Patents

Literature

42results about How to "Realize clamping limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

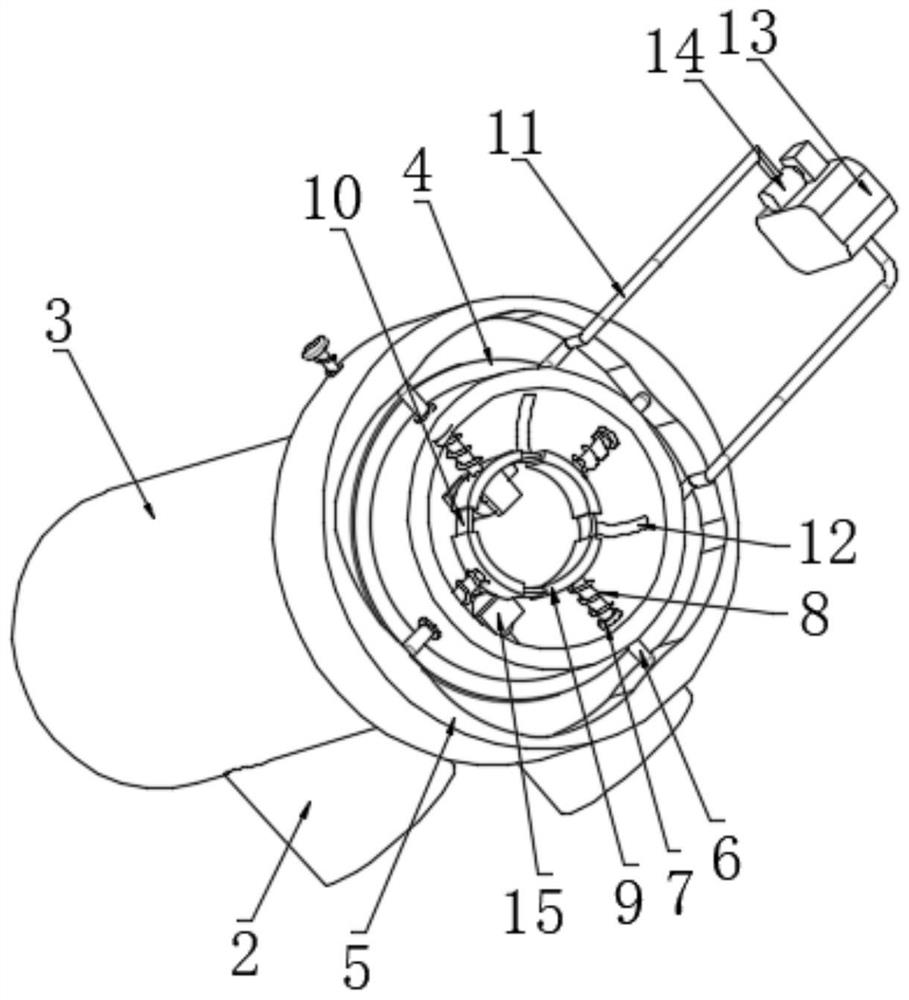

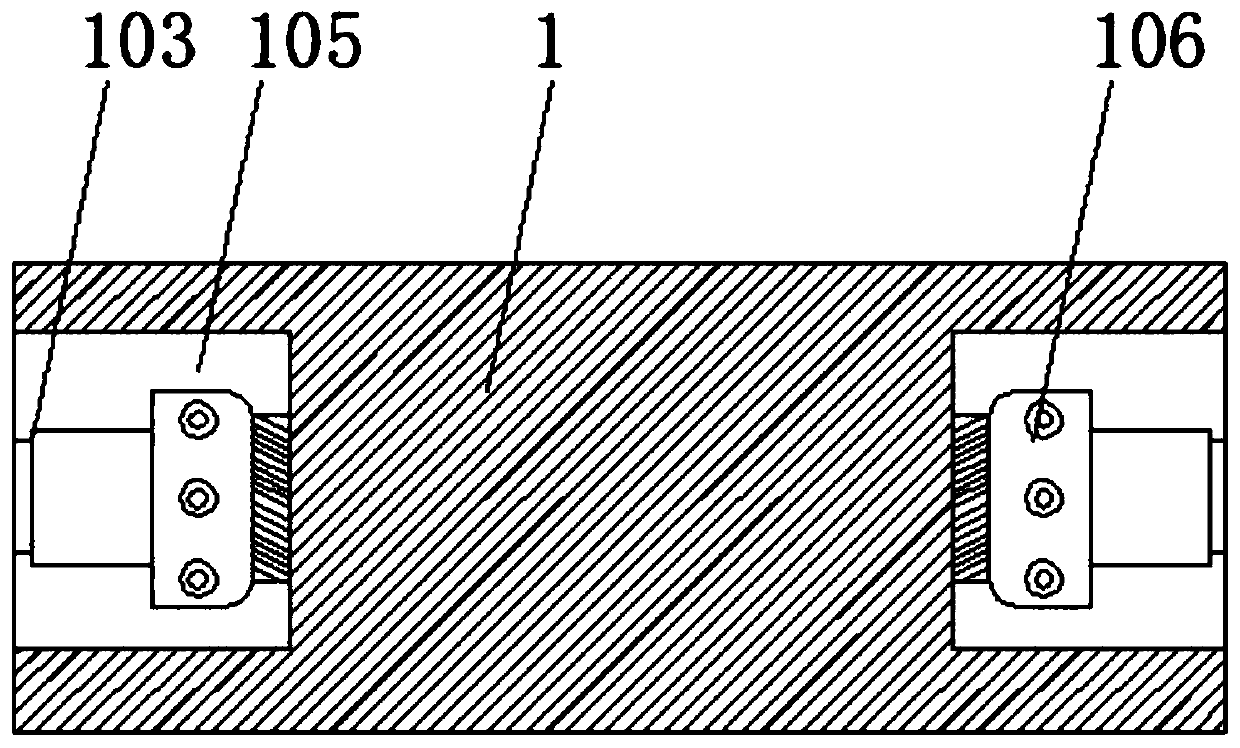

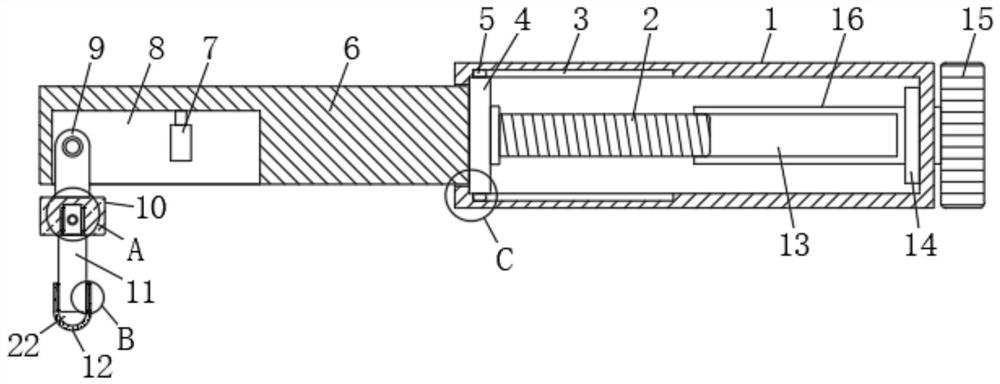

Marine pipeline flange with sealing structure

PendingCN112096983ARealize clamping limitFirmly connectedFlanged jointsSelf-bailing equipments/scuppersWater leakageMarine engineering

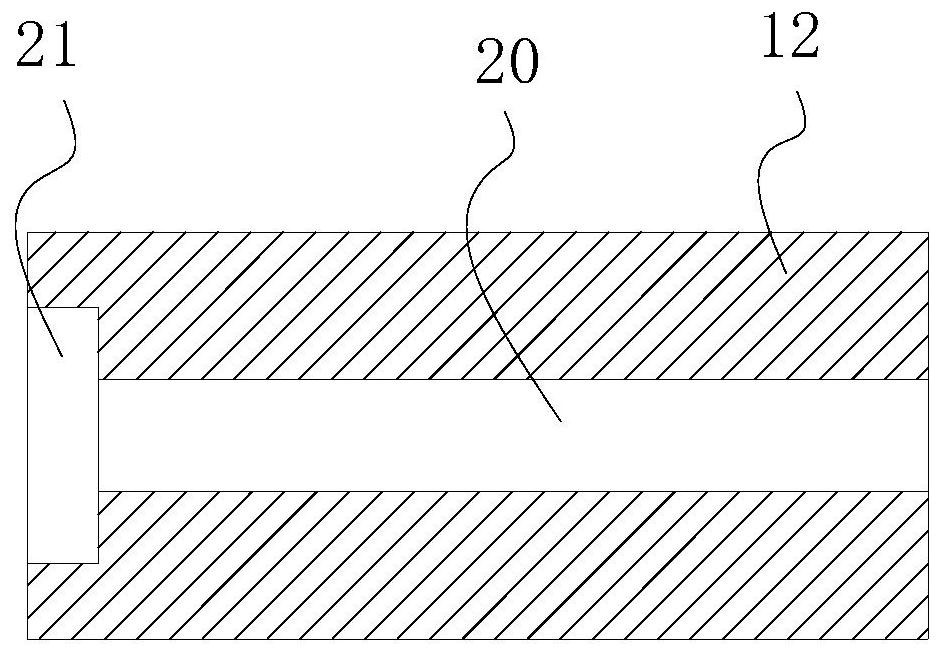

The invention discloses a marine pipeline flange with a sealing structure. A butt flange is arranged on one side of a fixed flange, a driven pipe is connected to the middle of the side wall of one side of the butt flange, a threaded column is connected to the butt flange and is connected in a threaded groove by a thread, a threaded rod is connected to a telescopic column, a mounting groove is formed in the middle of the inner part of the telescopic column, and the end, located in the mounting groove, of a screw is rotatably connected to a clamping plate. A telescopic motion of the telescopic column can be controlled effectively by the spring, and the connecting stability and the sealing property can be improved effectively through the threaded column, the threaded groove and the sealing property, so that excellent end stability of the pipeline in vibration of stormy waves can be still kept, and water leakage of the pipeline is avoided effectively. Openings of a main pipeline and a slave pipeline are attached tightly by way of threaded plugging, so that the problem of water leakage can be avoided effectively. Rubber gaskets are fixed to the side walls of the opposite sides of a joining plate and a flange plate, so that the sealing effect can be further improved.

Owner:JINGJIANG FUYUAN SHIP FITTINGS CO LTD

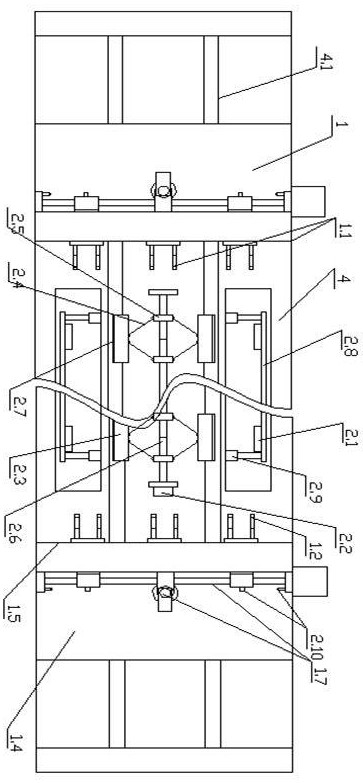

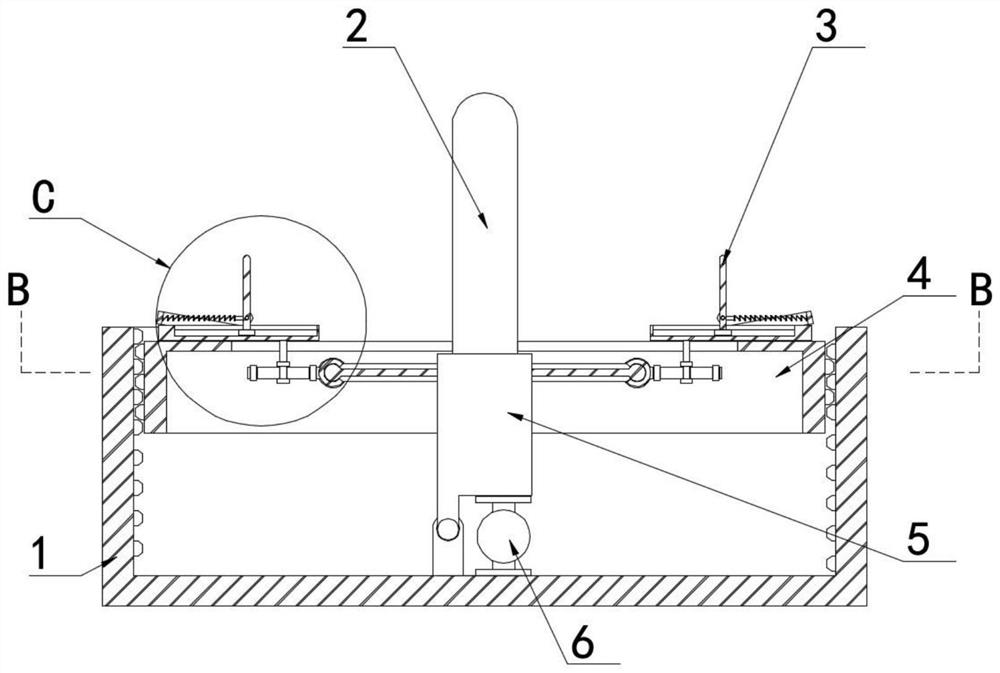

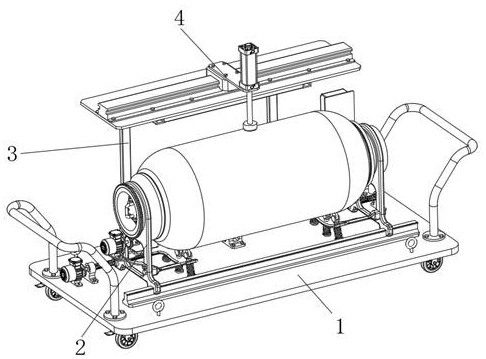

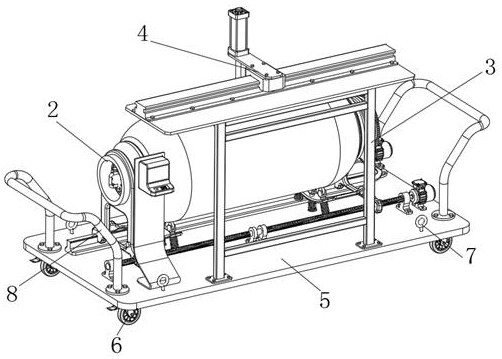

Pipeline container product machining and welding equipment with multi-directional positioning function

ActiveCN113878276ARealize clamping limitRapid coolingWelding/cutting auxillary devicesAuxillary welding devicesWater flowStructural engineering

The invention discloses pipeline container product machining and welding equipment with a multi-directional positioning function, and particularly relates to the technical field of welding machining. The pipeline container product machining and welding equipment comprises a bottom plate, the bottom ends of four fixing columns on the upper surface of the bottom plate are fixedly connected, and the top ends of the two fixing columns on the left side are fixedly connected with the lower surface of the same placing cylinder. According to the pipeline container product machining and welding equipment, a rotary extrusion cylinder, limiting rods, clamping plates, first elastic assemblies, a communicating water pipe, a water inlet pipe, a water outlet pipe, a connecting pump, supporting wheels and a welding head are arranged, and meanwhile, the close faces of the four clamping plates stably clamp the outer surface of a pipeline, so that clamping and limiting of the pipeline are achieved. Meanwhile, after welding is completed, water flows in a communicating water pipe through the water inlet pipe and the water outlet pipe, heat of a welding part is rapidly taken away for cooling by adopting non-contact type water cooling, and rapid cooling after welding is completed can be achieved while smooth and stable positioning in the welding process is achieved. the device has good welding stability and efficiency.

Owner:WUHAN FULI MACHINERY MFG CO LTD

Magnetic attraction locating automobile internal star wheel center hole polishing device

ActiveCN107891322AEasy to adjustPrevent slidingGrinding carriagesRevolution surface grinding machinesEngineeringElectromagnet

The invention discloses a magnetic attraction locating automobile internal star wheel center hole polishing device which comprises stop blocks, an electromagnetic guide block, a rotating shaft, a telescopic rod, a base and an internal star wheel; the upper end of the base is fixedly connected with an upright column; the top end of the upright column is fixedly connected with a limiting stopper; the part, below the limiting stopper, of the upright column is sleeved with an upper beam plate; a motor is arranged at the part, on one side of the upright column, of the top end of the upper beam plate; the bottom end of the motor is connected with the rotating shaft; a grinding sheet is arranged at the bottom end of the rotating shaft; the middle part of the upright column is connected with a fixing bracket; the electromagnetic guide block is arranged on the fixing bracket; electromagnet sleeves are arranged at the bottom of the electromagnetic guide block; inner guide cylinders are arrangedin the electromagnet sleeves; a coil is wound between each inner guide cylinder and the corresponding electromagnet sleeve; and iron-core rods penetrate through the inner guide cylinders. Height adjustment is realized when the grinding sheet carries outer rotating polishing; ball way limiting balls at the bottom ends of the iron-core rods are clamped into ball ways of the internal star wheel, so that clamping and limiting on the internal star wheel are realized, and the stability is good; and operation is convenient and quick, and no manual clamping or fixing is required.

Owner:安徽赢廷智能装备有限公司

Automatic smearing and rotating equipment for round cakes

ActiveCN113491278AApply evenlyEasy to operateFouling preventionBaked articles handlingElectric machineEngineering

The invention relates to rotating equipment, and in particular relates to automatic smearing and rotating equipment for round cakes. The technical problem of the invention is to provide the automatic smearing and rotating equipment for round cakes, and the equipment can realize automatic cleaning of a smearing scraping blade and limiting of the cakes. According to the technical scheme, the automatic smearing and rotating equipment for round cakes comprises a bottom plate, a motor, a first rotating shaft, a first belt, a rotating disc and a movable disc, the motor is arranged in the middle of one side of the bottom plate, the first rotating shaft is rotationally connected to the middle of the bottom plate, the first belt is wound between the middle of the first rotating shaft and an output shaft of the motor, the rotating disc is arranged at the top of the first rotating shaft, and the top of the rotating disc is slidably connected with a movable disc. Through cooperation of a material scraping mechanism and a material spraying mechanism, cream can be automatically sprayed to a cake, meanwhile, the cream can be evenly smeared to the cake, and operation is easy.

Owner:GANZHOU LIANGHUA FEIER SNOW FOOD CO LTD

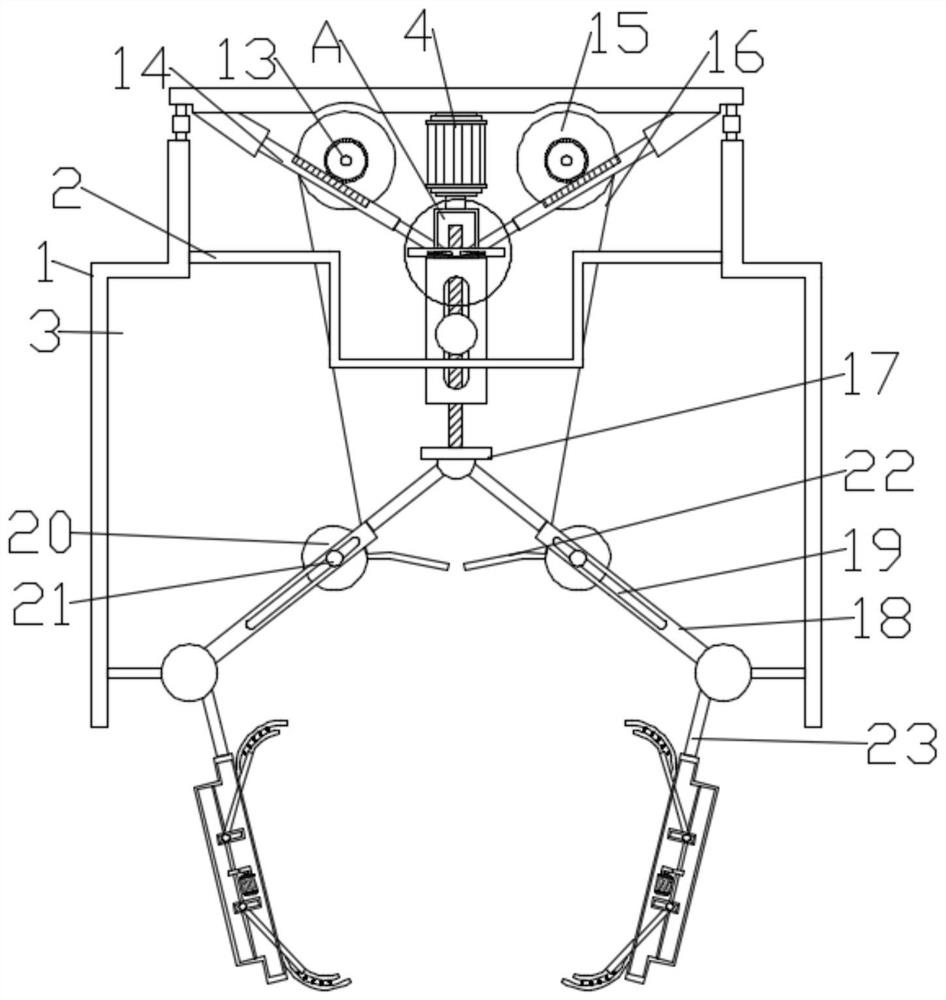

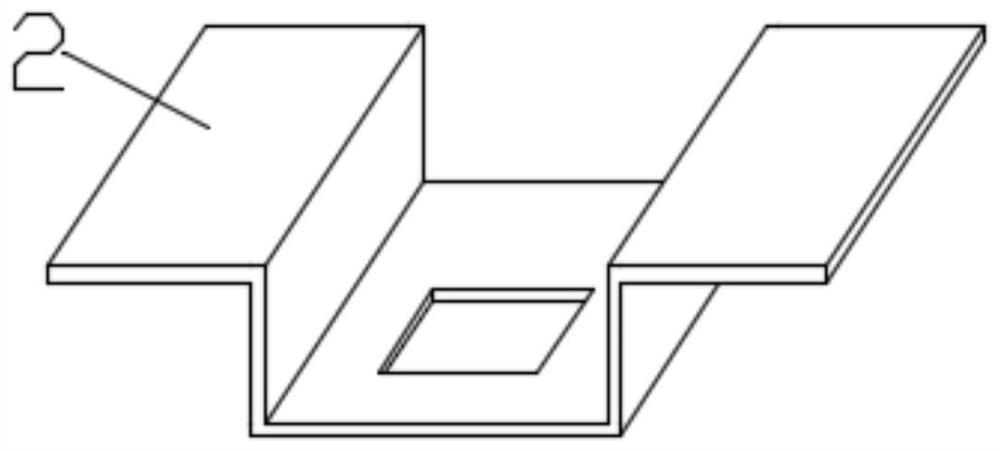

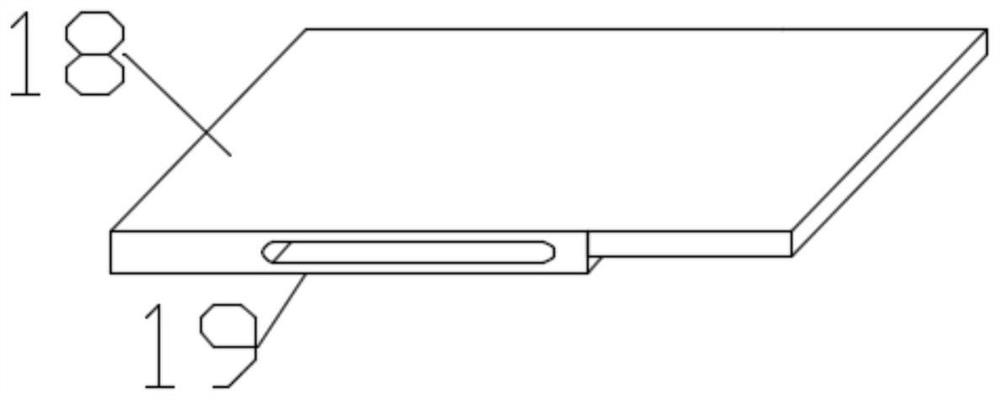

Automatic workpiece clamping device for industrial machining

The invention discloses an automatic workpiece clamping device for industrial machining, belongs to the technical field of automation, and solves the problem that the clamping range of a mechanical claw of an existing device cannot be adjusted, so that the practicability of the device is low. The device comprises a shell, a working cavity is formed in the shell, a positioning seat is arranged in the middle of the working cavity, a driving assembly is arranged at the top of the working cavity, the driving assembly is connected with an auxiliary assembly, and the auxiliary assembly is connected with a clamping assembly. The device is provided with a grabbing assembly, due to the grabbing assembly, workpiece grabbing is achieved, falling of workpieces with types can be avoided, through the arrangement of a pressing plate, clamping and limiting of a workpiece are achieved, meanwhile, the effect of protecting the workpiece can be achieved, meanwhile, the clamping range of the clamping assembly is flexible and adjustable, and the application range of the device is widened.

Owner:苏州君洹自动化设备有限公司

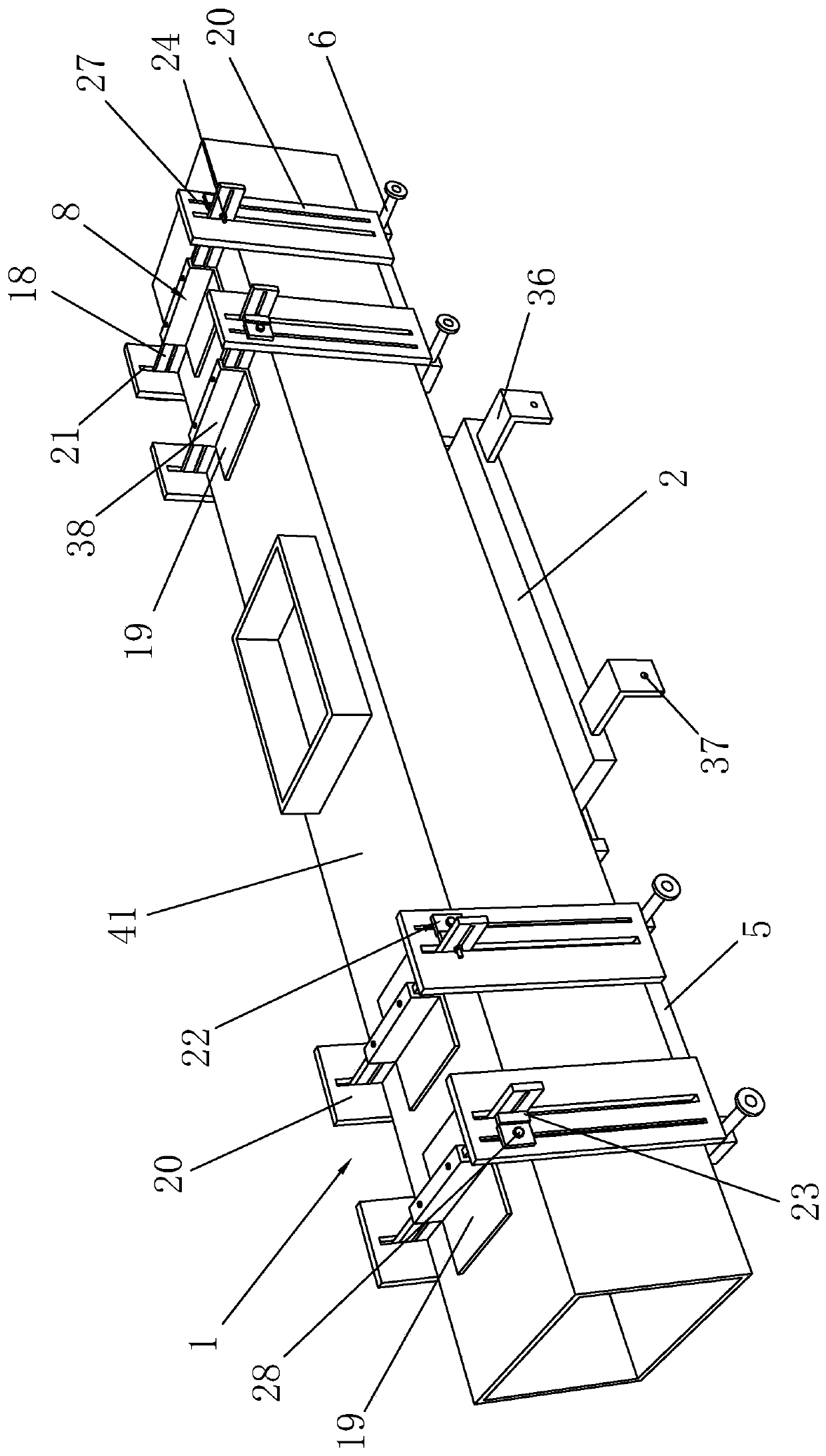

Material conveying equipment for building construction and use method thereof

InactiveCN111498738ARealize clamping limitInhibit sheddingSafety devices for lifting equipmentsLifting framesArchitectural engineeringMechanical engineering

The invention discloses material conveying equipment for building construction and a use method thereof, and belongs to the technical field of constructional engineering. The material conveying equipment for building construction comprises a sleeve column and a base, a moving assembly is mounted on the bottom of the base, the sleeve column is fixedly mounted on the top of the base, a lifting mechanism is mounted on the interior and the outer surface of the sleeve column in a penetrating manner, an extension column is movably mounted at the position, on the inner side of the sleeve column, of the top of the lifting mechanism, according to the material conveying equipment for building construction and the use method thereof, according to different needs of thicknesses and sizes of an actually-conveyed plate or regular rectangular material, an adjusting rod is manually twisted for real-time rotation, an inner side thread of an adjusting hole drives an upper abutting plate to move downwards in a twisting manner, the upper abutting plate and a lower abutting plate can be in abut limit with the top and the bottom of the plate or the regular rectangular building material, clamping and fixing of the conveying material can be achieved, and building material automatic falling in the conveying process can be prevented.

Owner:倪官杰

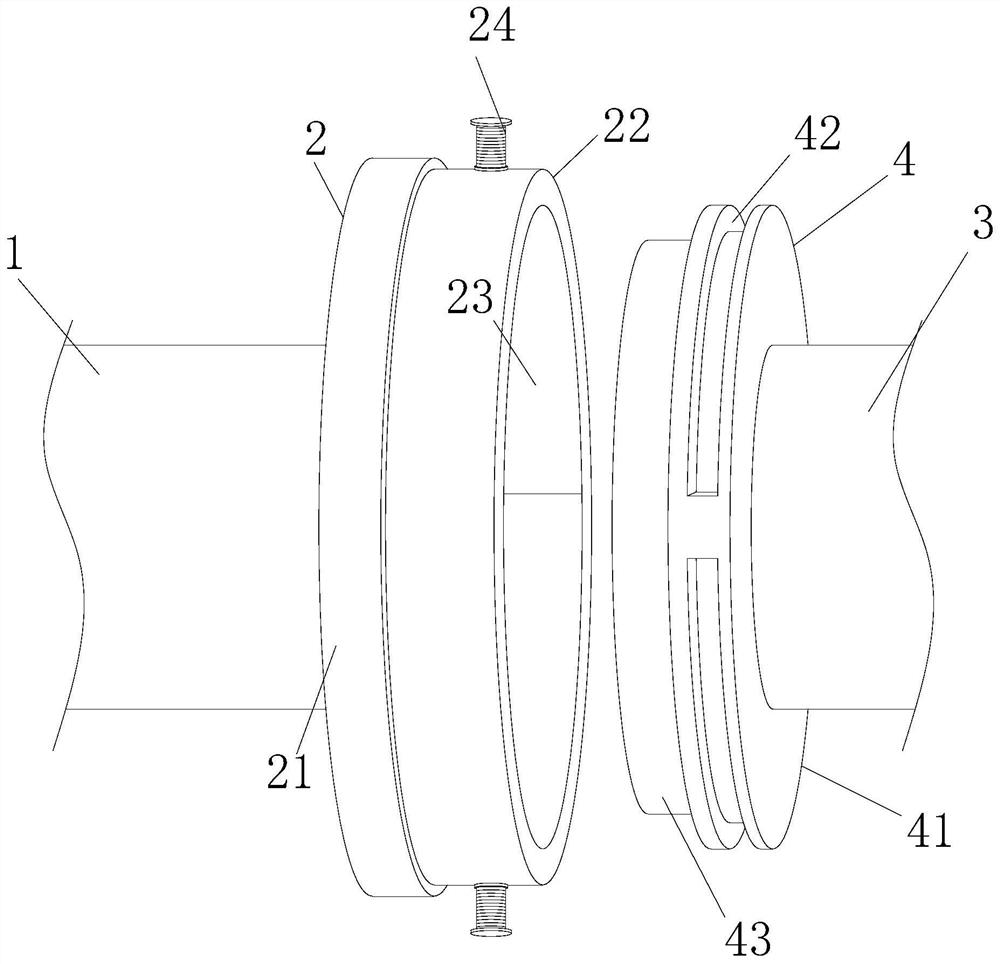

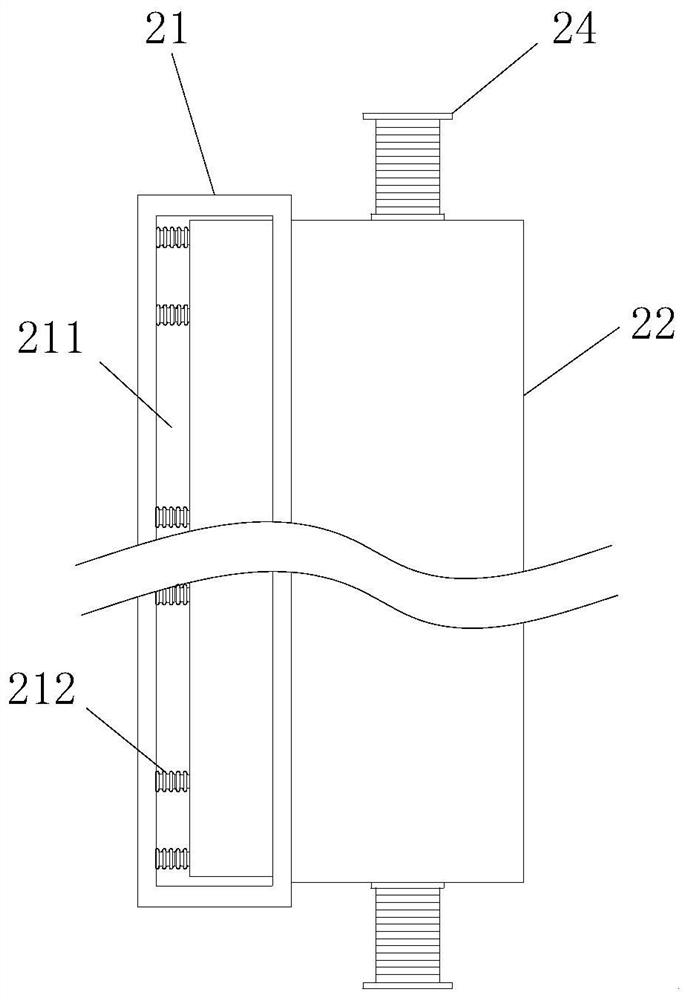

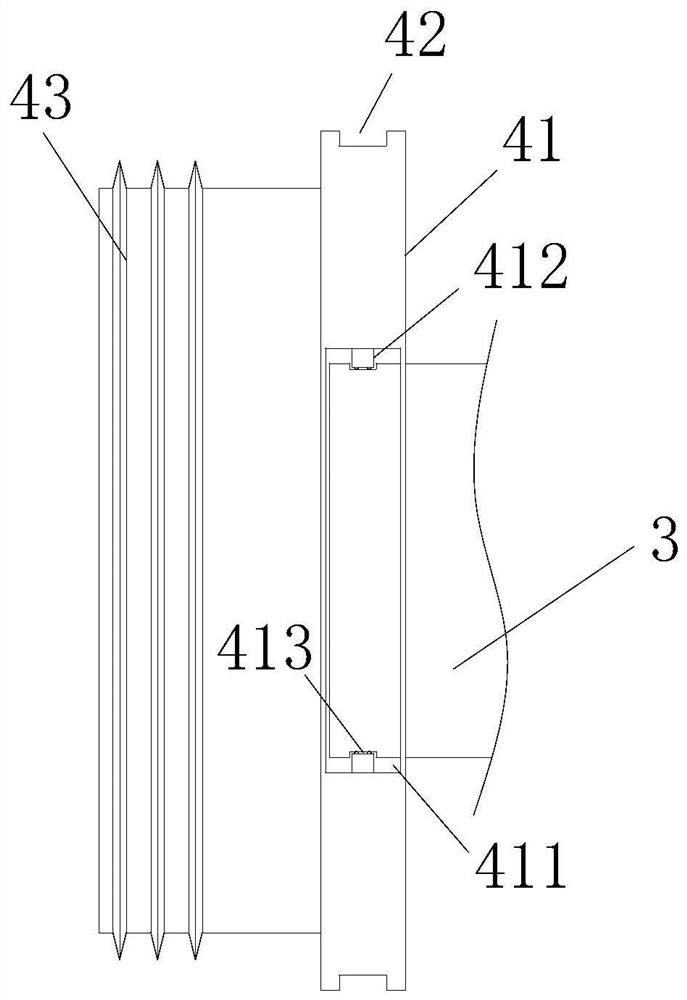

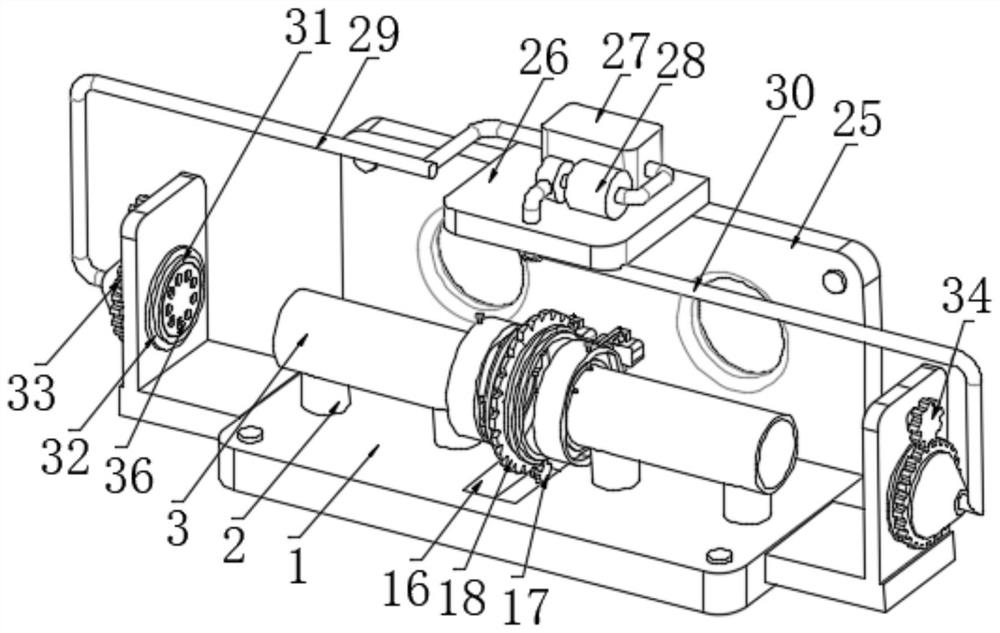

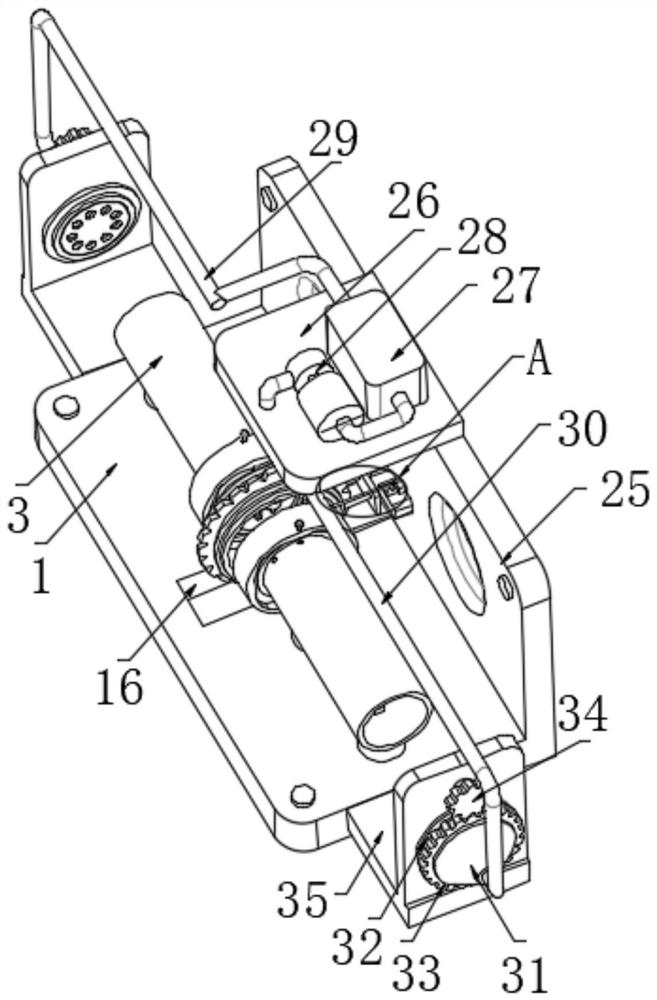

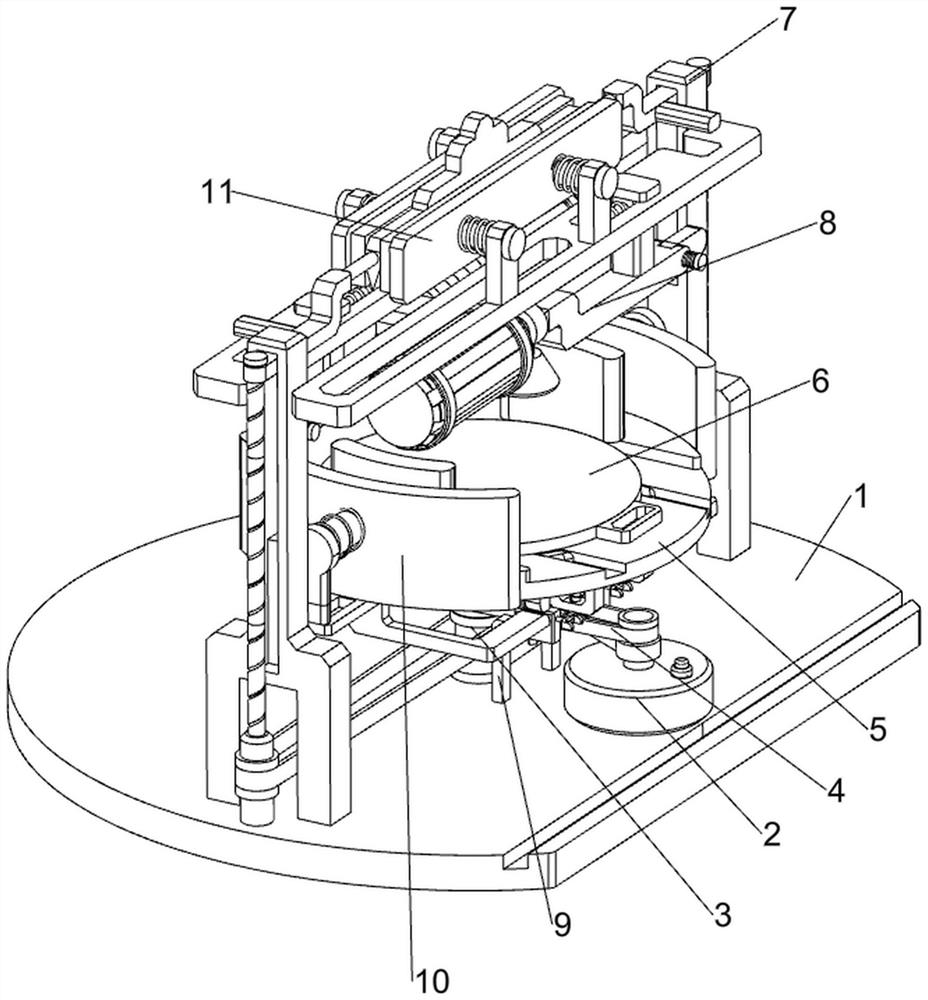

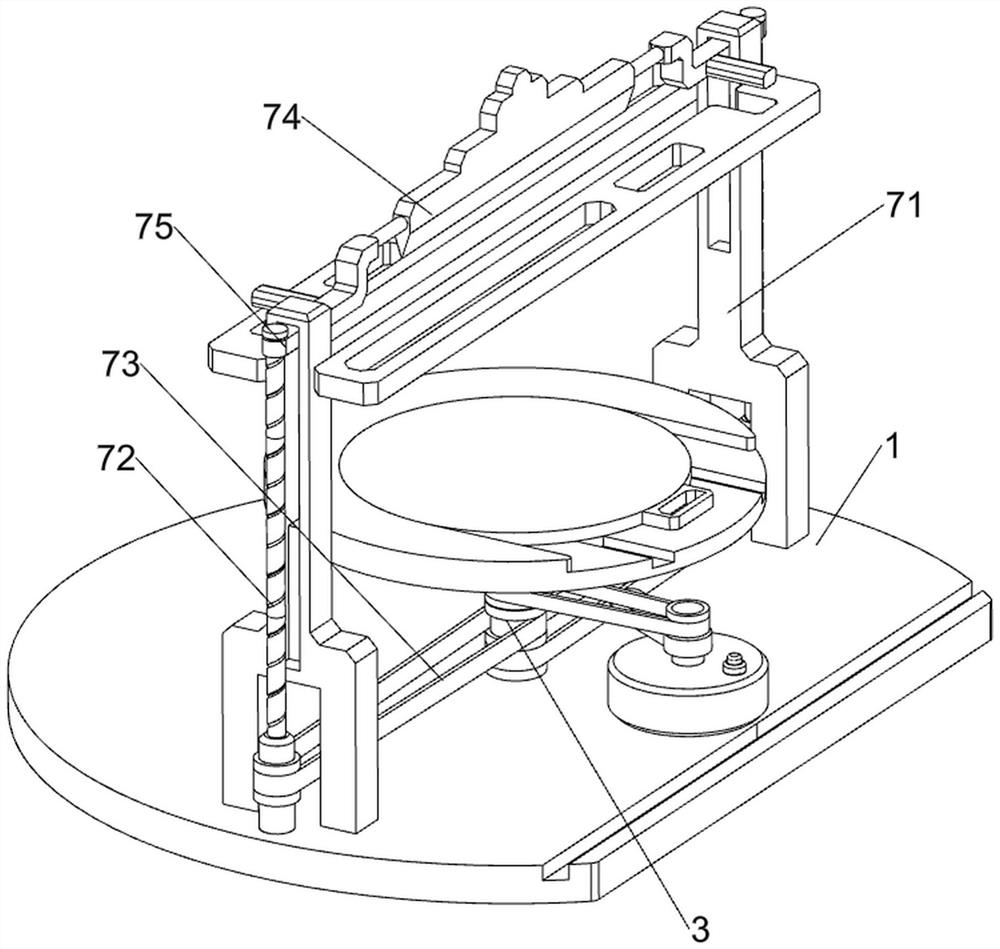

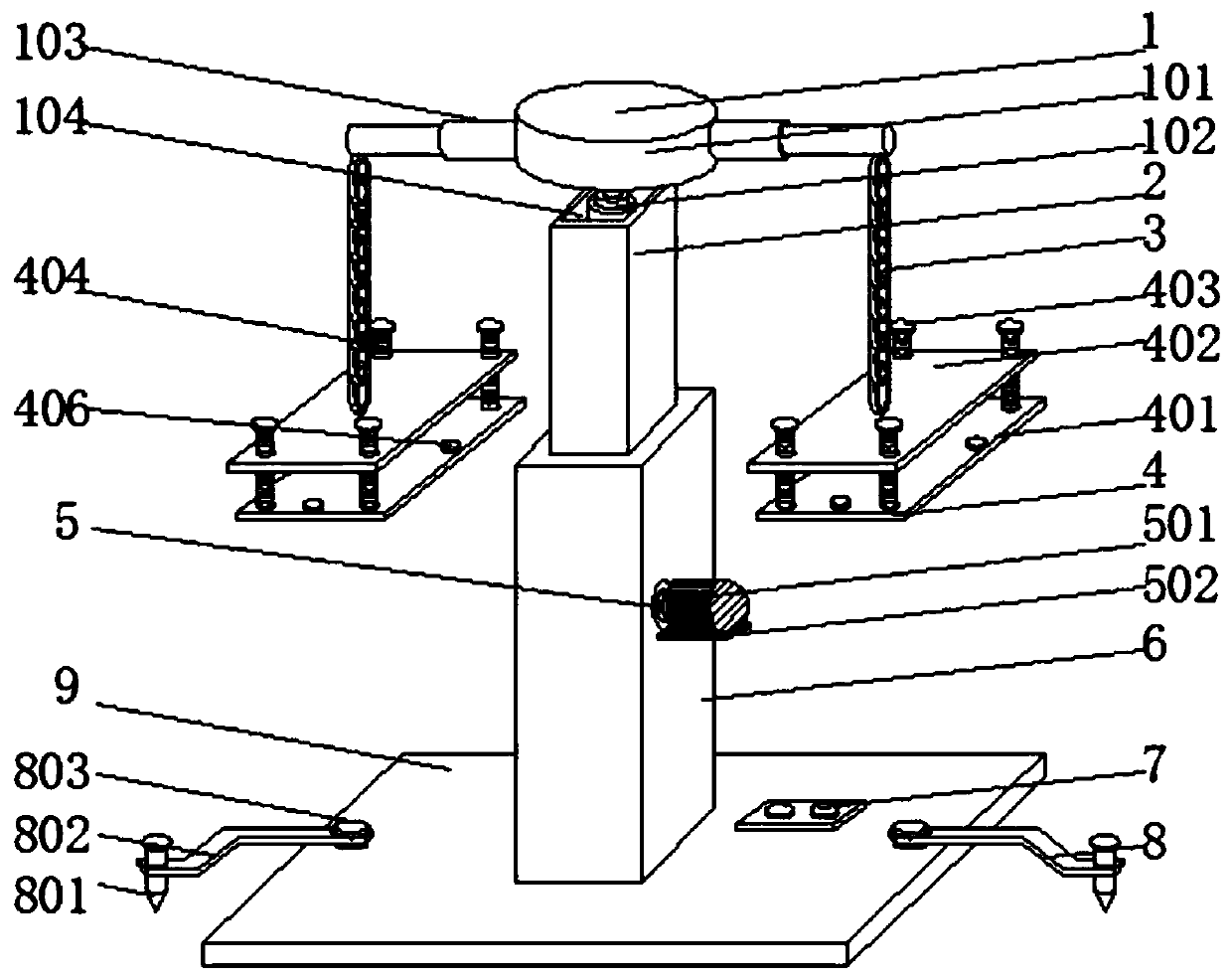

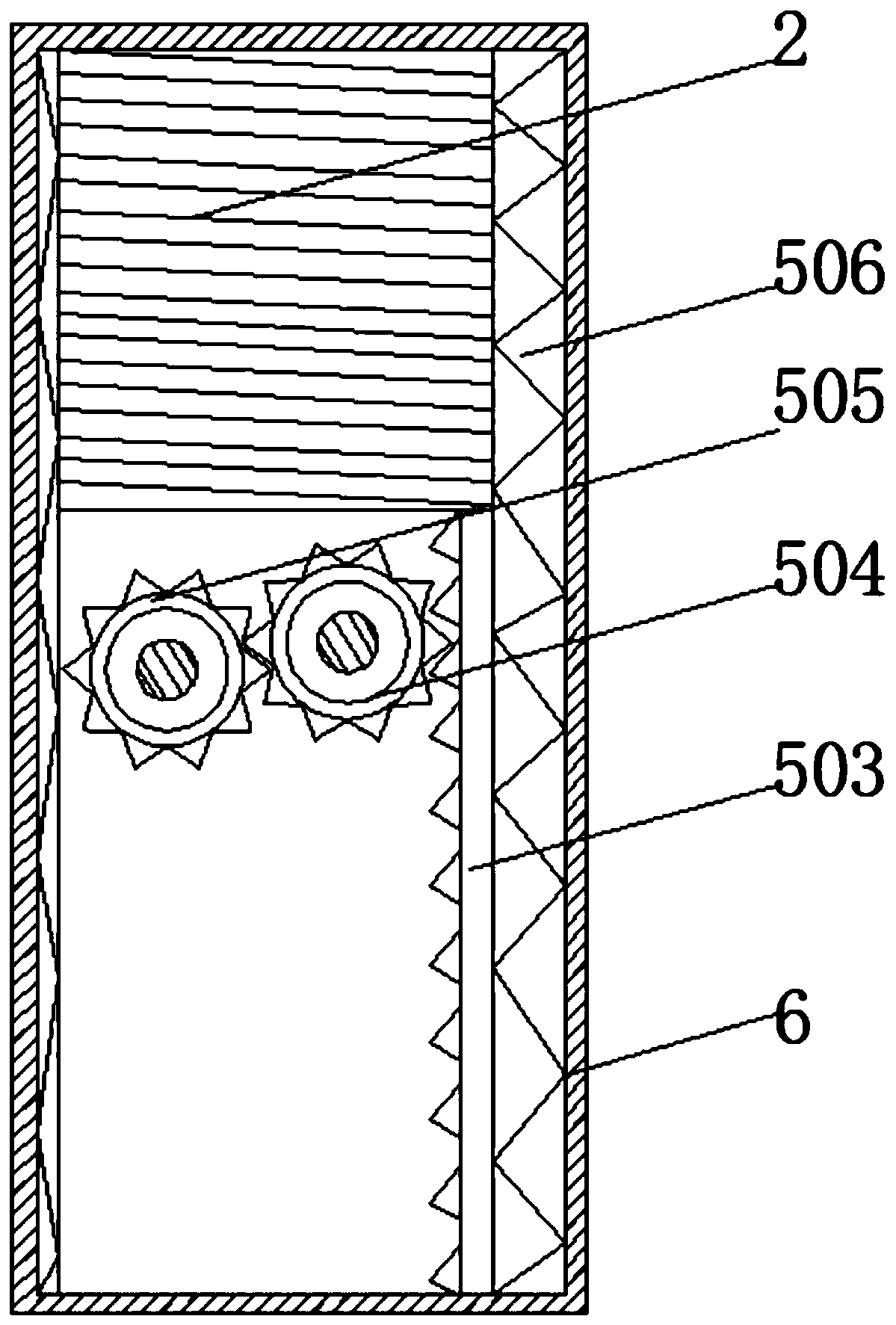

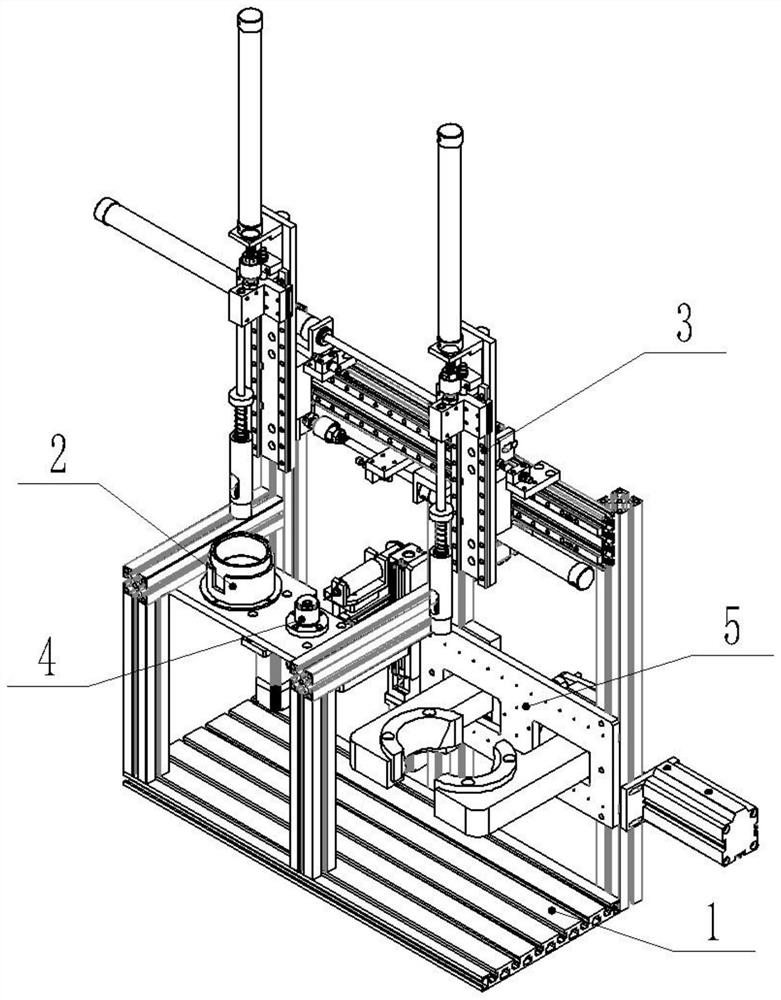

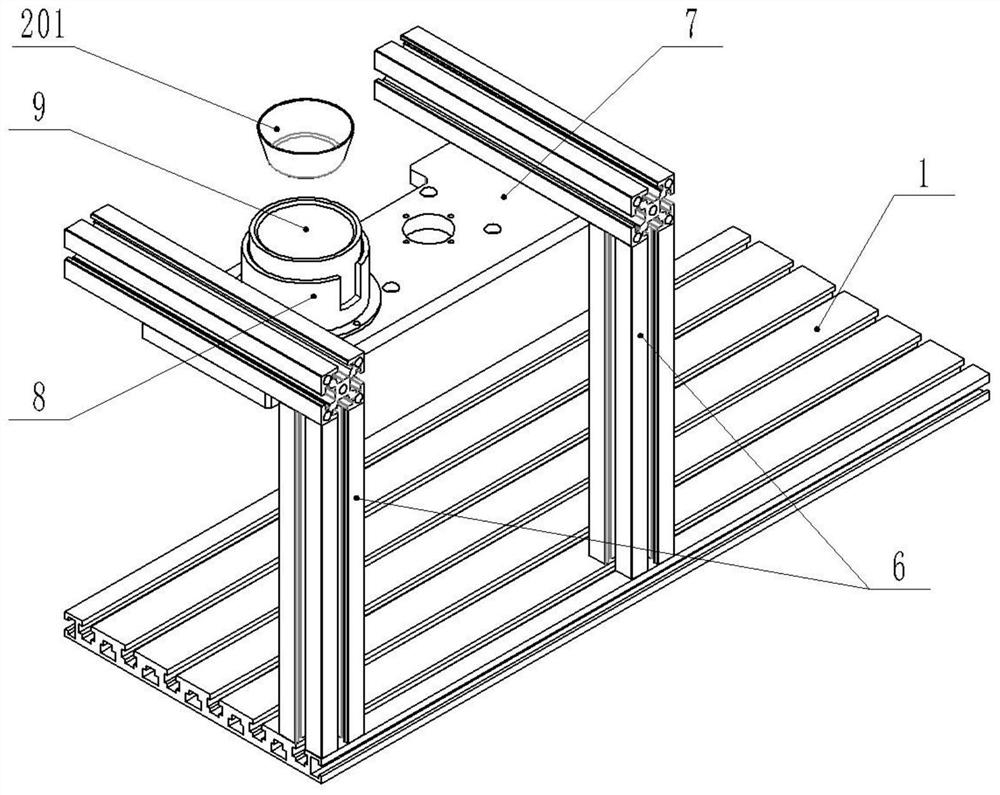

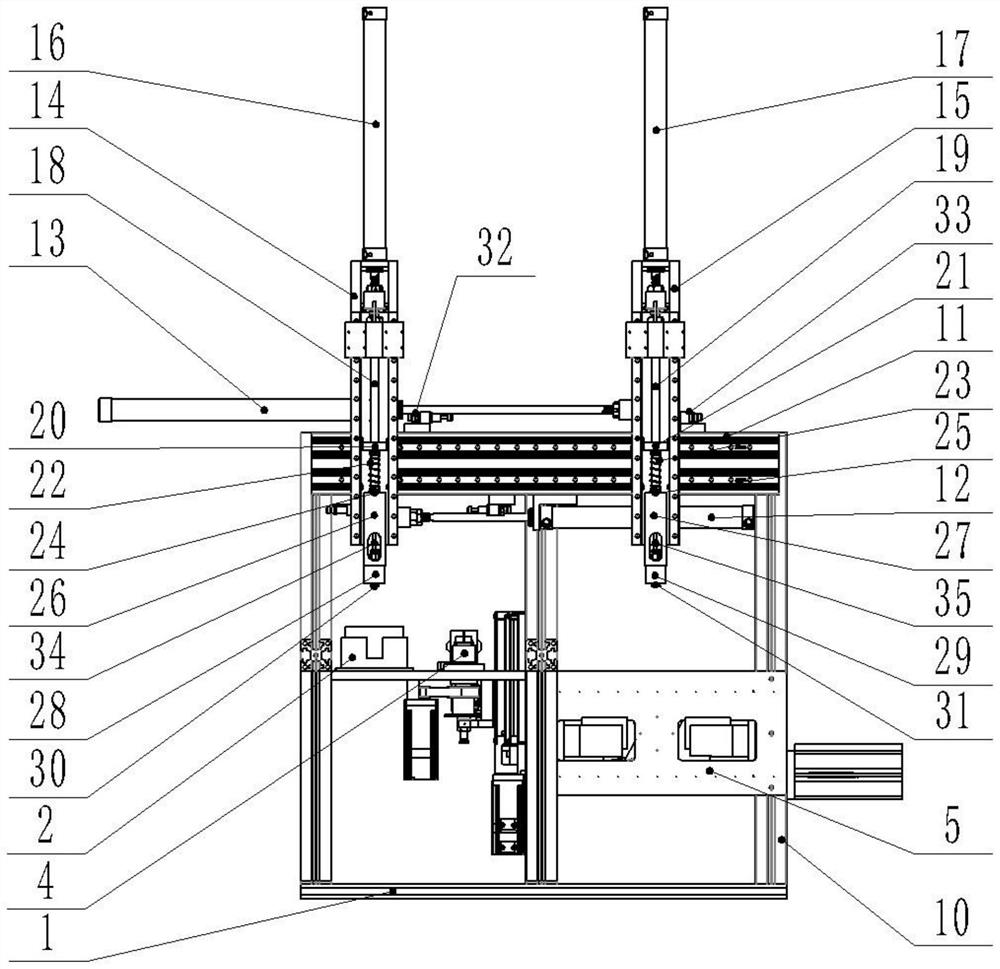

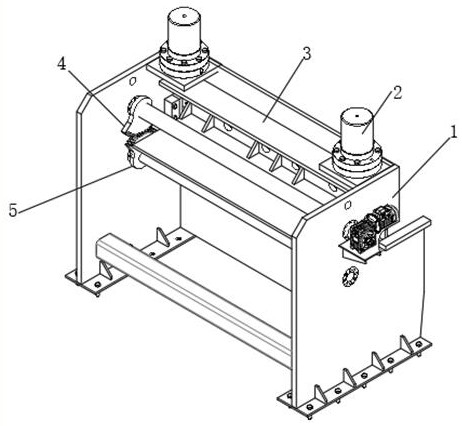

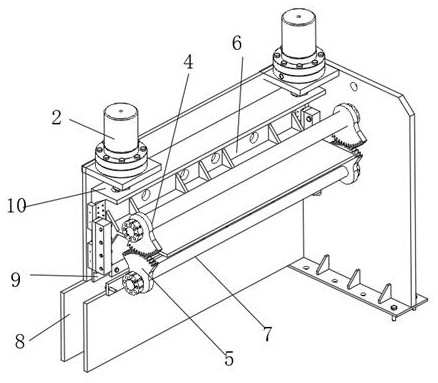

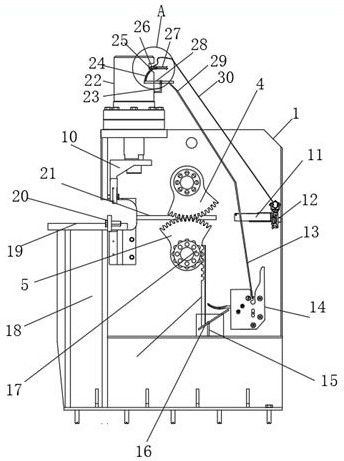

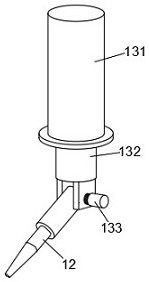

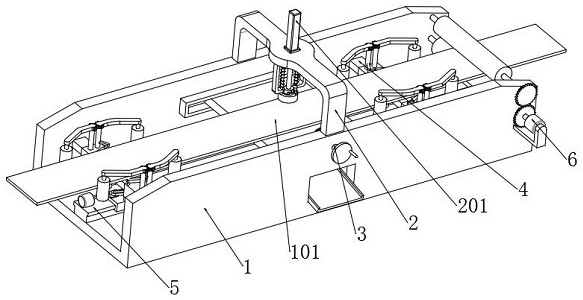

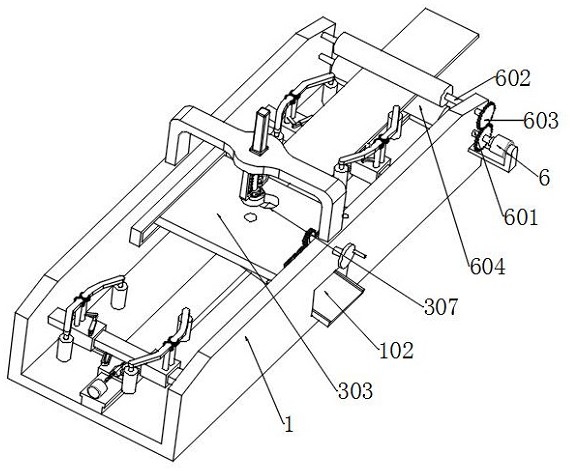

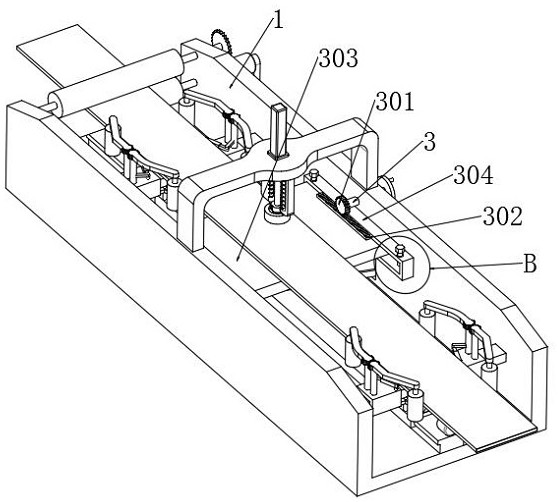

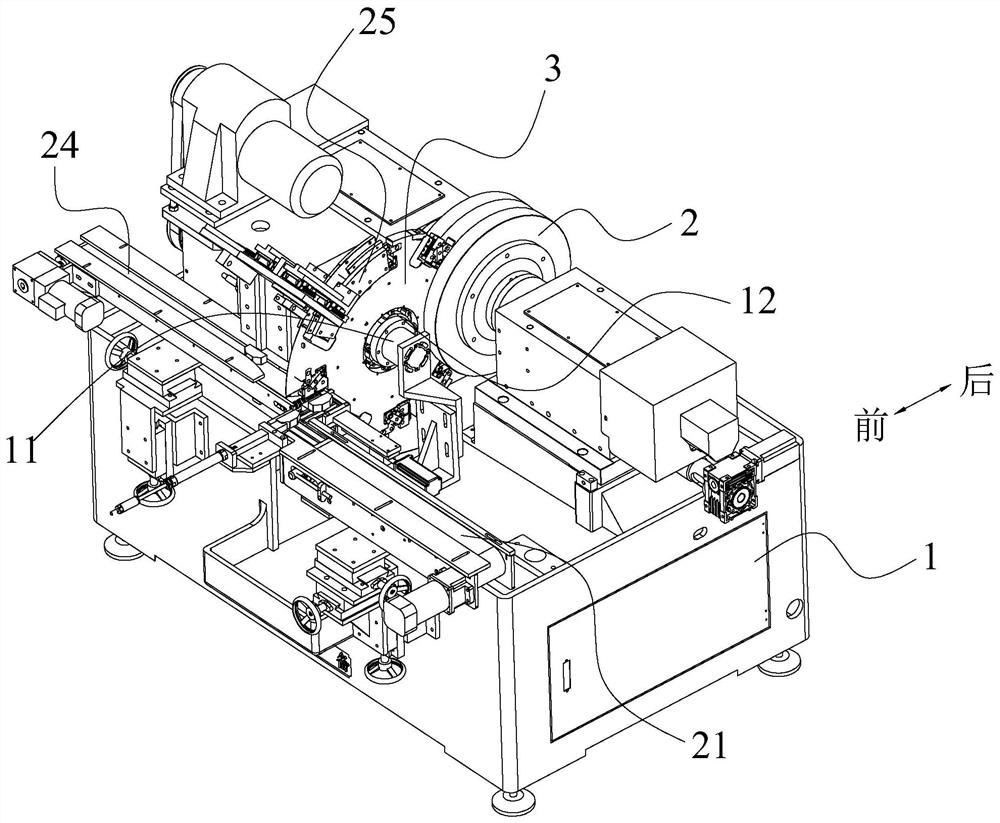

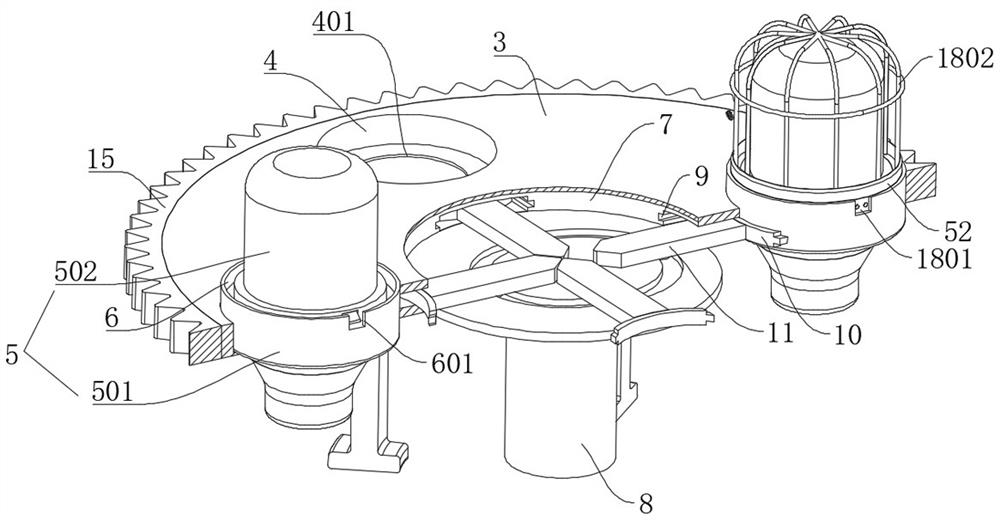

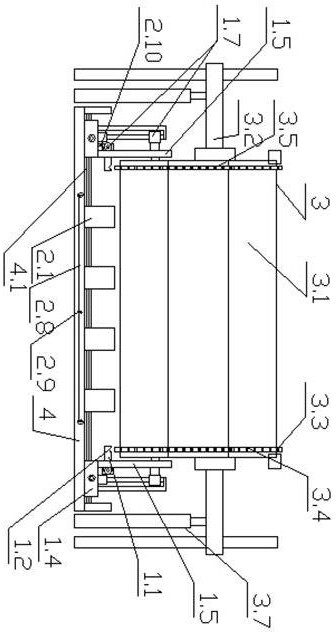

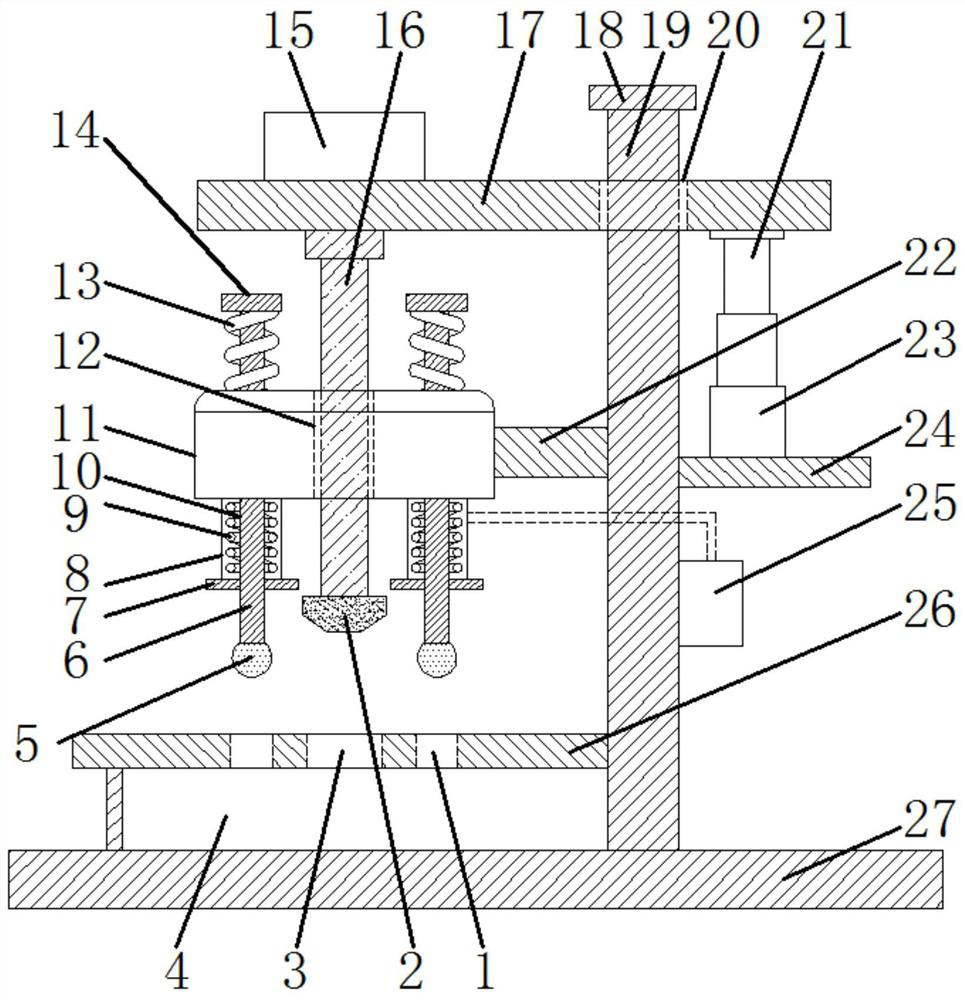

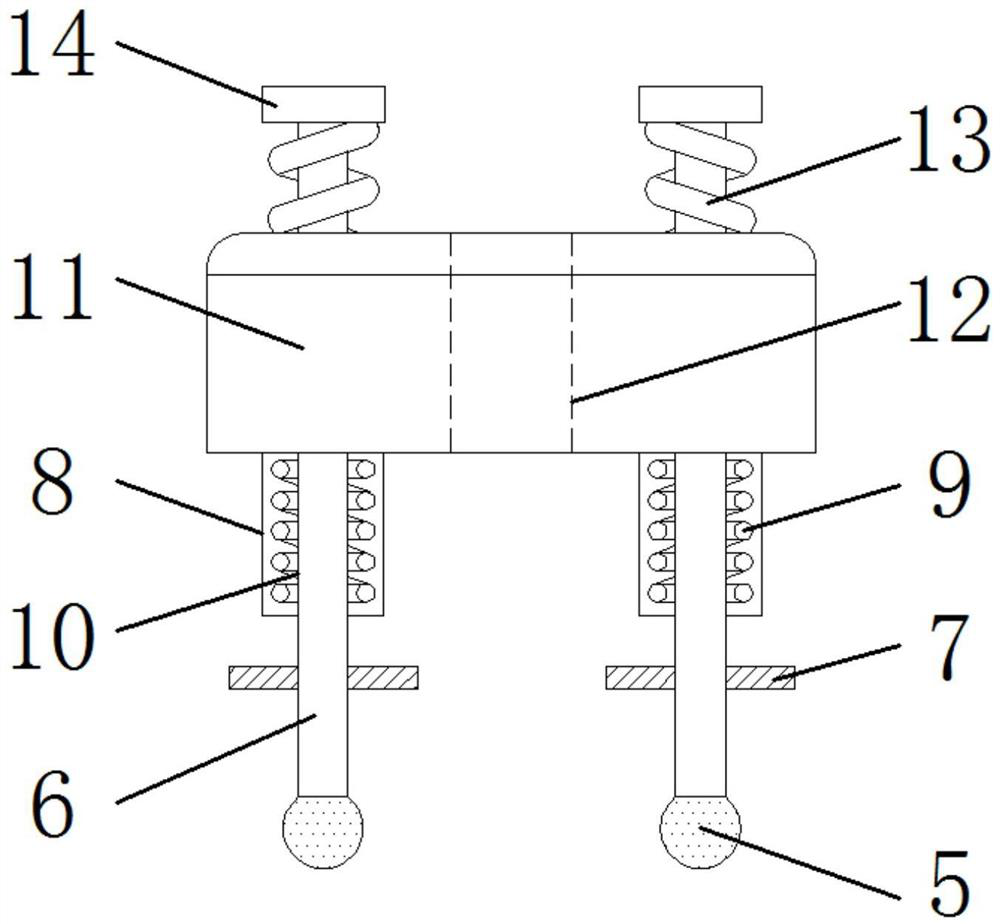

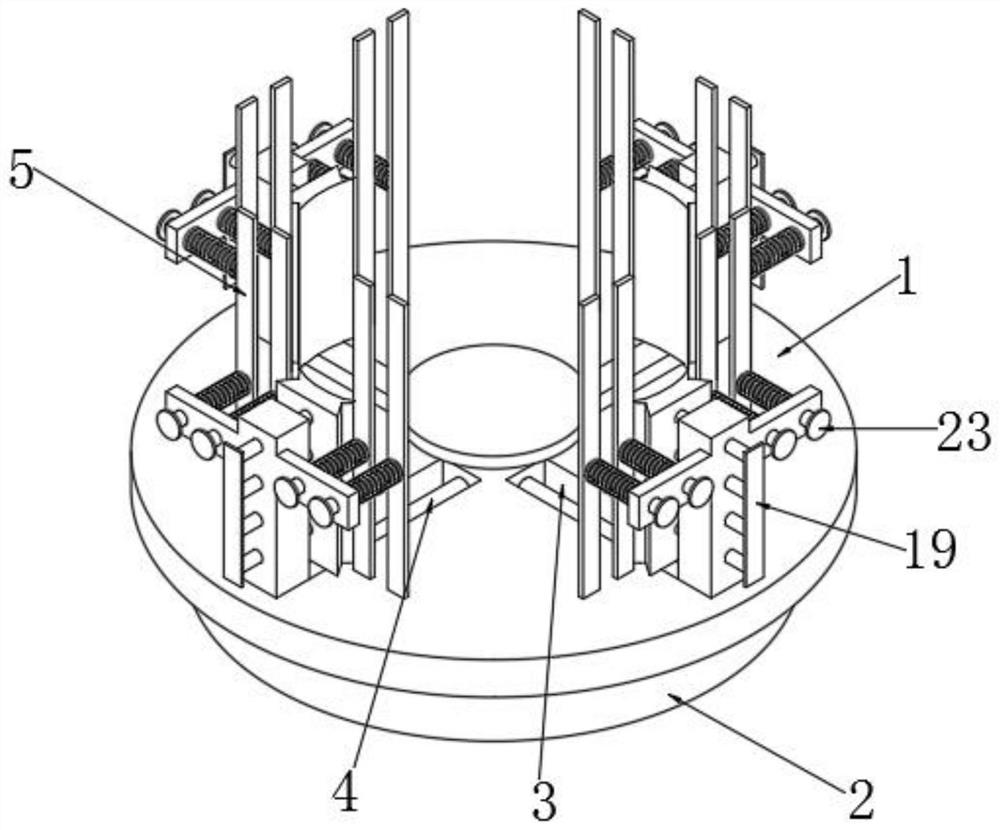

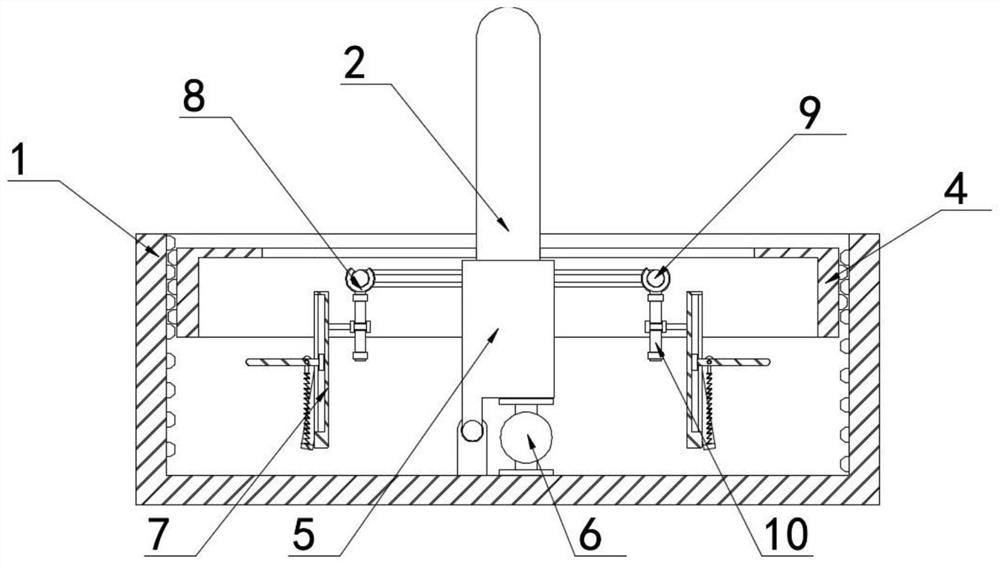

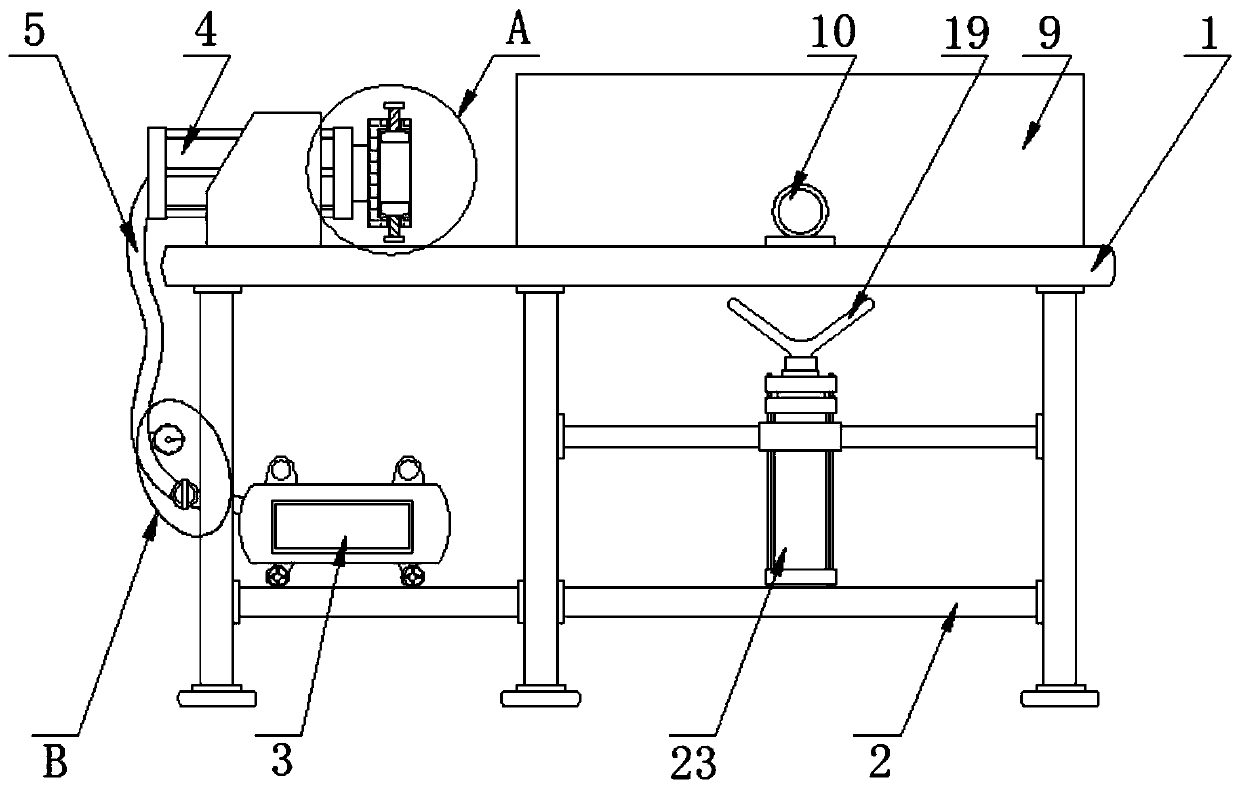

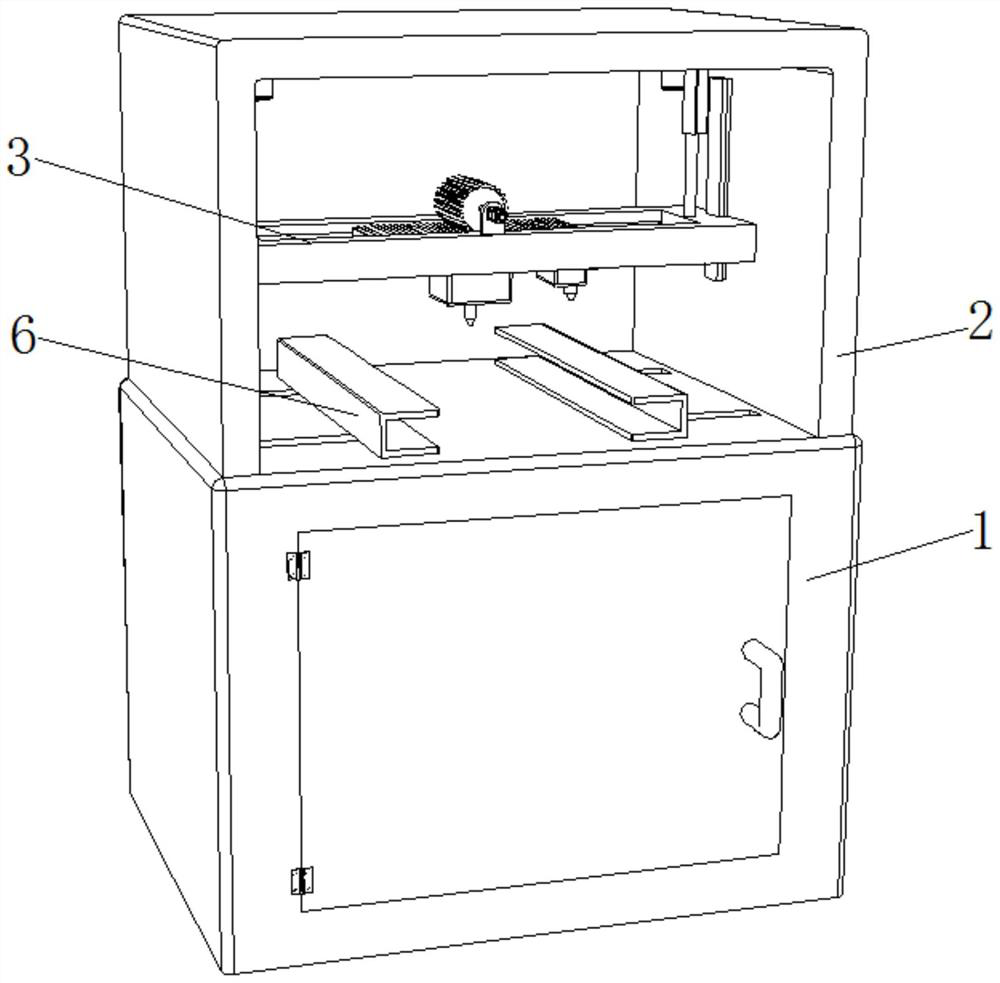

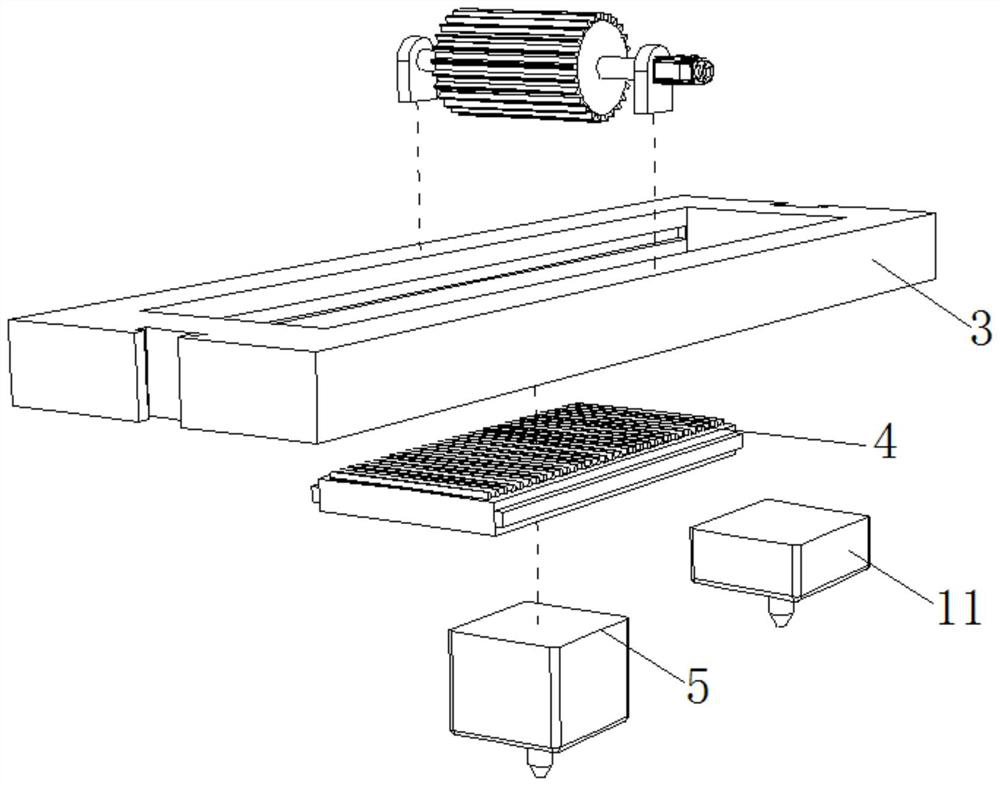

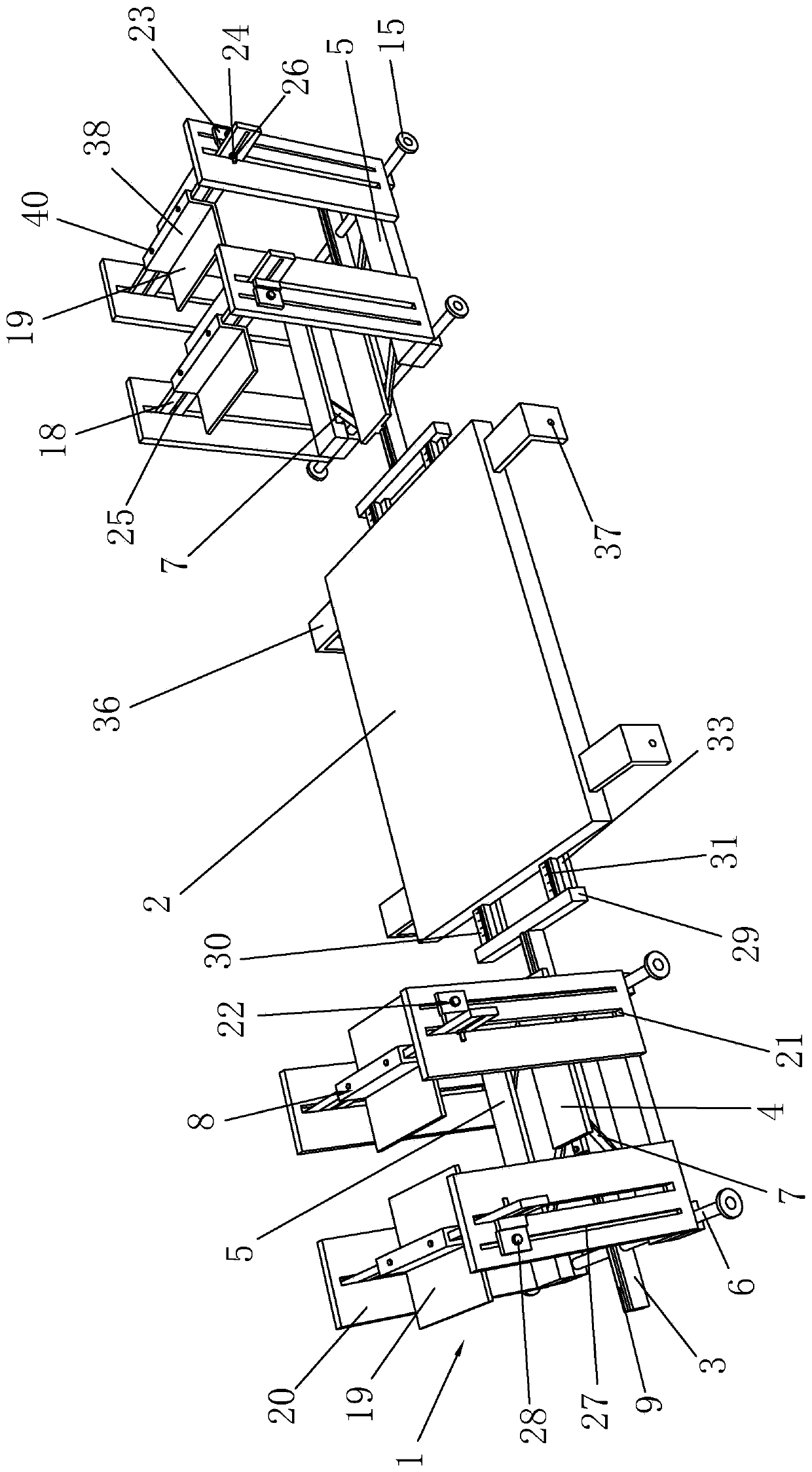

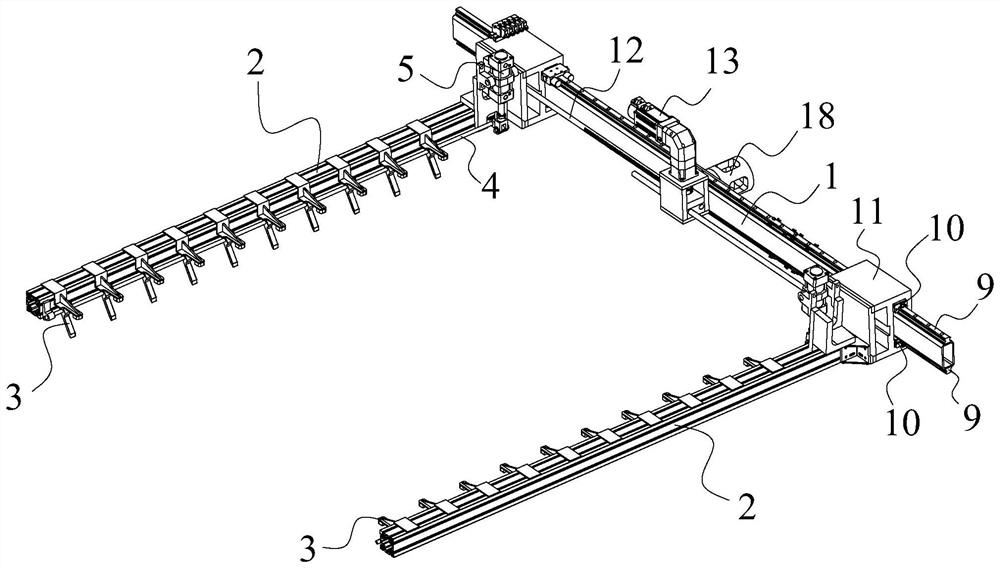

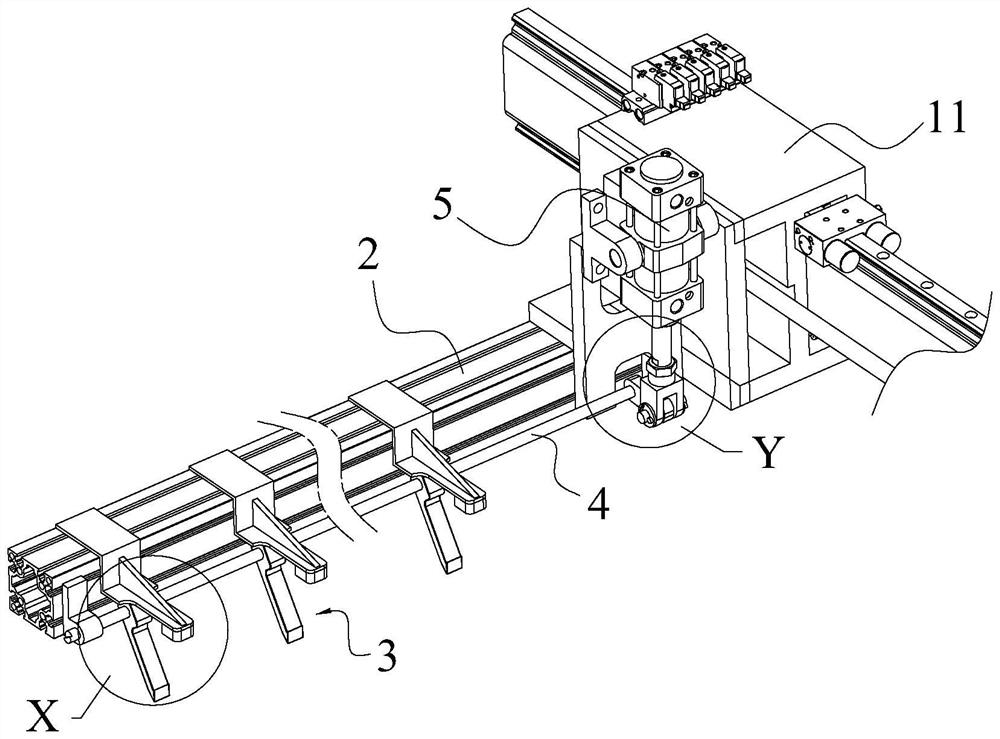

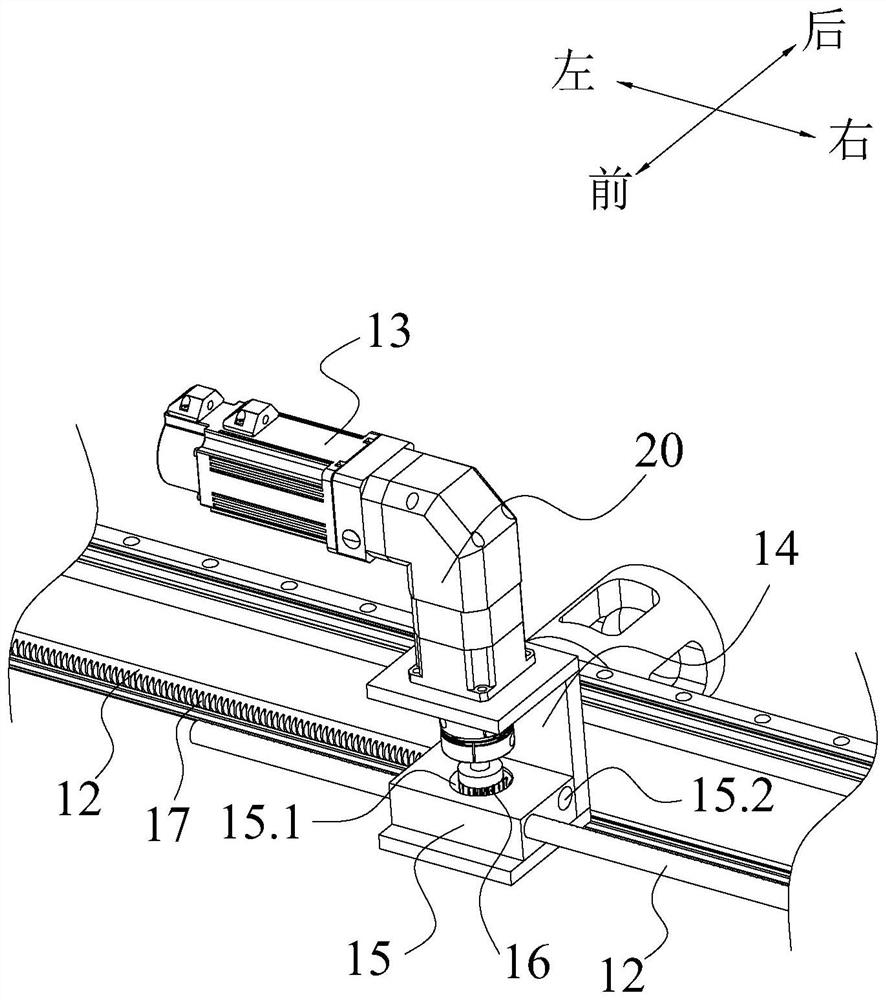

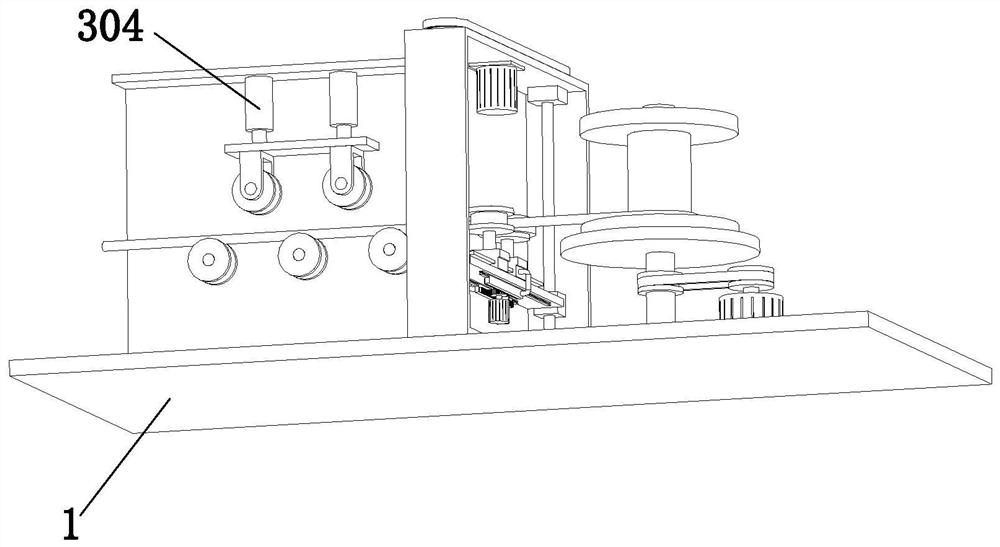

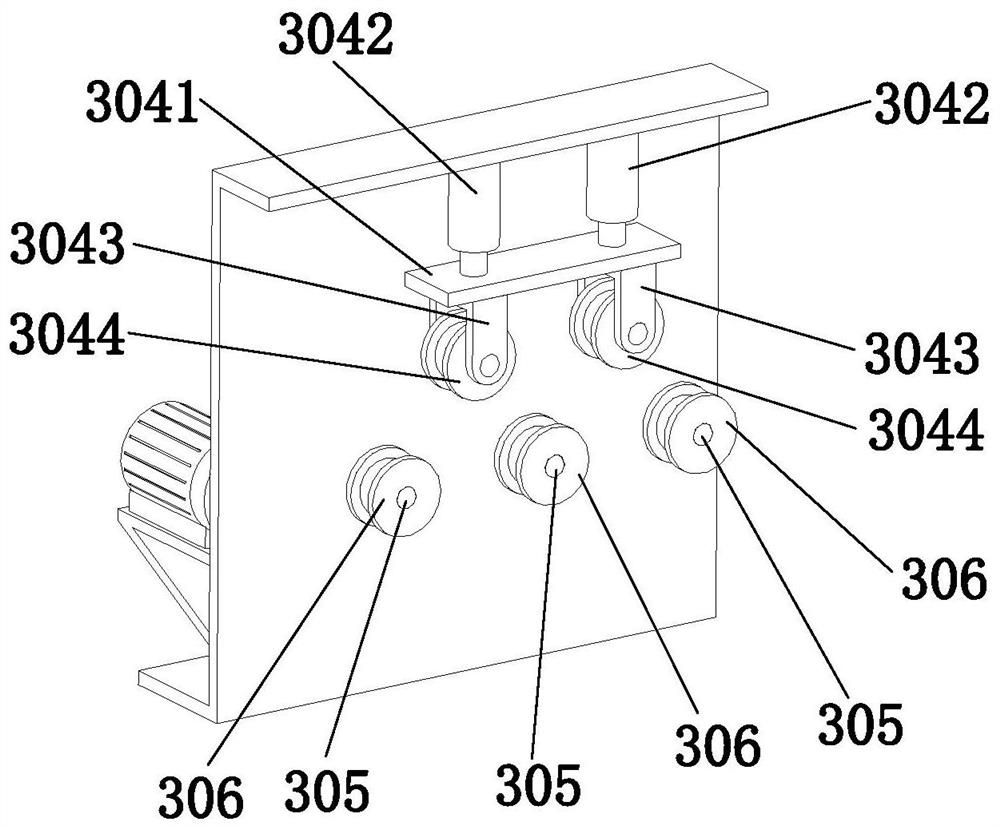

Automatic assembling device for nozzle closure of small solid rocket engine

ActiveCN111911504ARealize clamping limitSimple structureMaterial gluingMechanical componentsStructural engineering

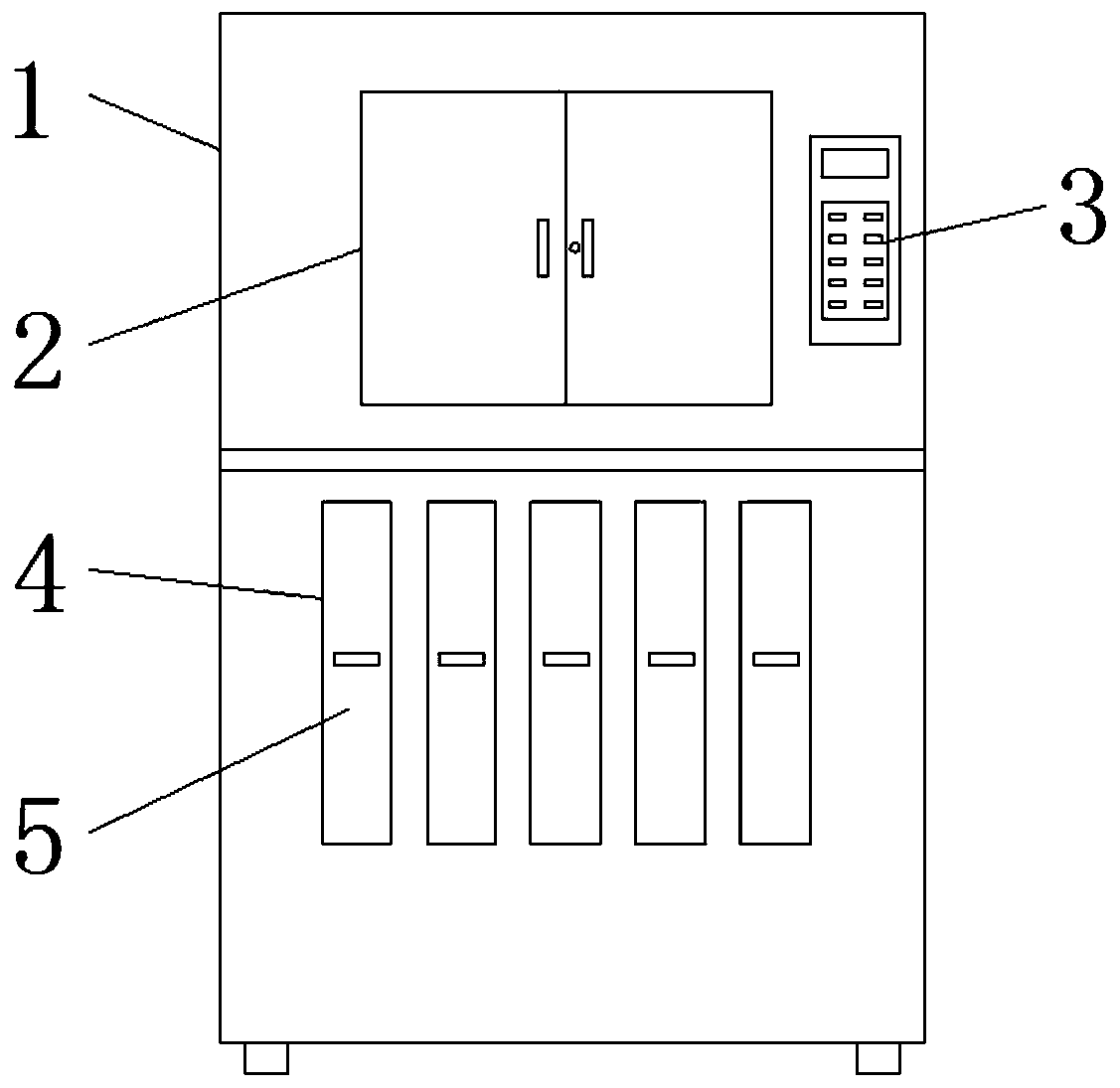

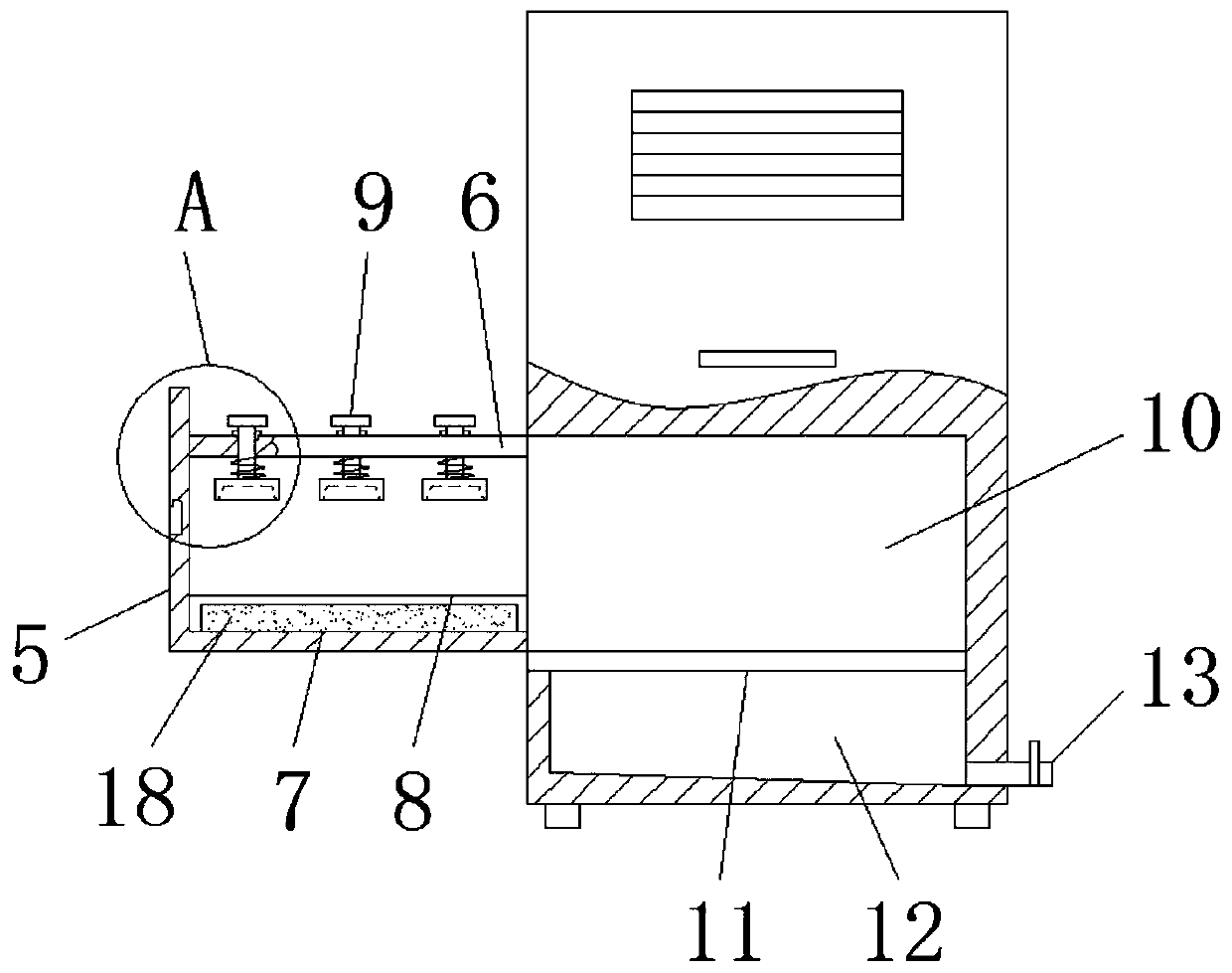

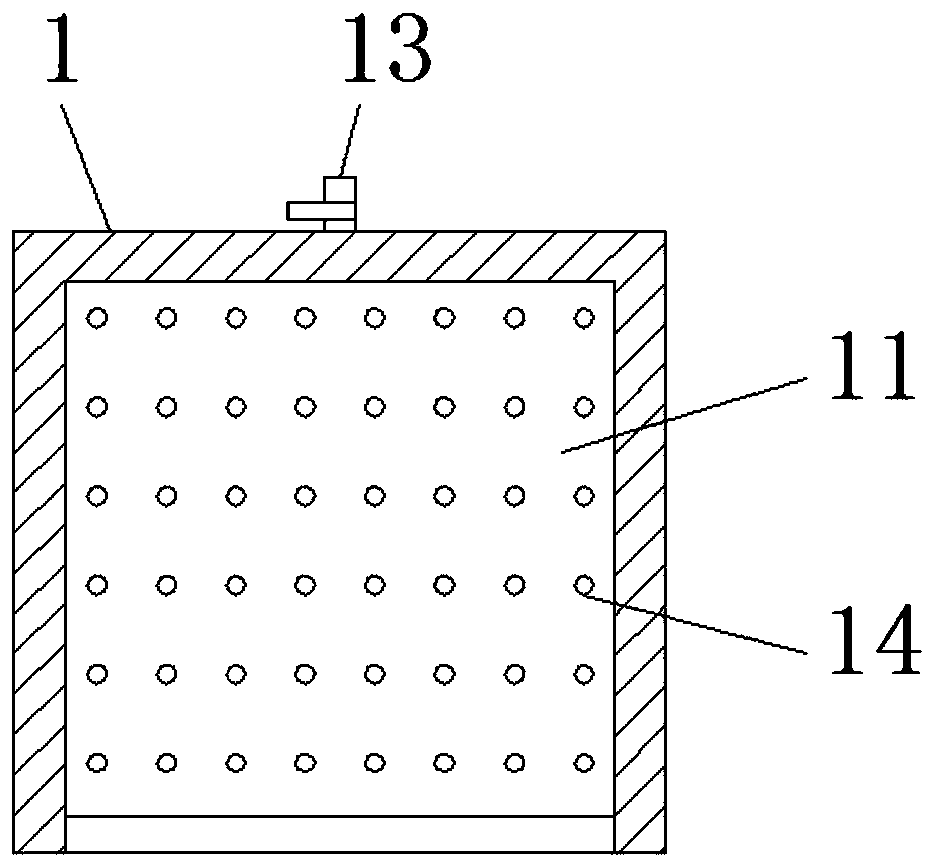

The invention discloses an automatic assembling device for a nozzle closure of a small solid rocket engine, and belongs to the field of assembly of mechanical parts of initiating explosive devices. The automatic assembling device comprises a bottom plate (1), a closure storage mechanism (2), a double-station closure carrying mechanism (3), an automatic gluing mechanism (4) and a nozzle clamping and limiting mechanism (5), wherein the closure storage mechanism (2) is arranged on the bottom plate (1) and is used for providing the closure for the double-station closure carrying mechanism (3); thedouble-station closure carrying mechanism (3) is used for carrying the closure in the closure storage mechanism (2) to the automatic gluing mechanism (4) for gluing, and carrying the glued closure tothe nozzle clamping and limiting mechanism (5) for closure bonding and compaction; the automatic gluing mechanism (4) is used for automatically gluing the outer conical surface of the closure; and the nozzle clamping and limiting mechanism (5) is used for enabling a nozzle mouth to be vertically clamped and positioned upwards, and meanwhile, is matched with the double-station closure carrying mechanism (3) to vertically put the glued closure into the inner conical surface of the nozzle to be bonded and compacted.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

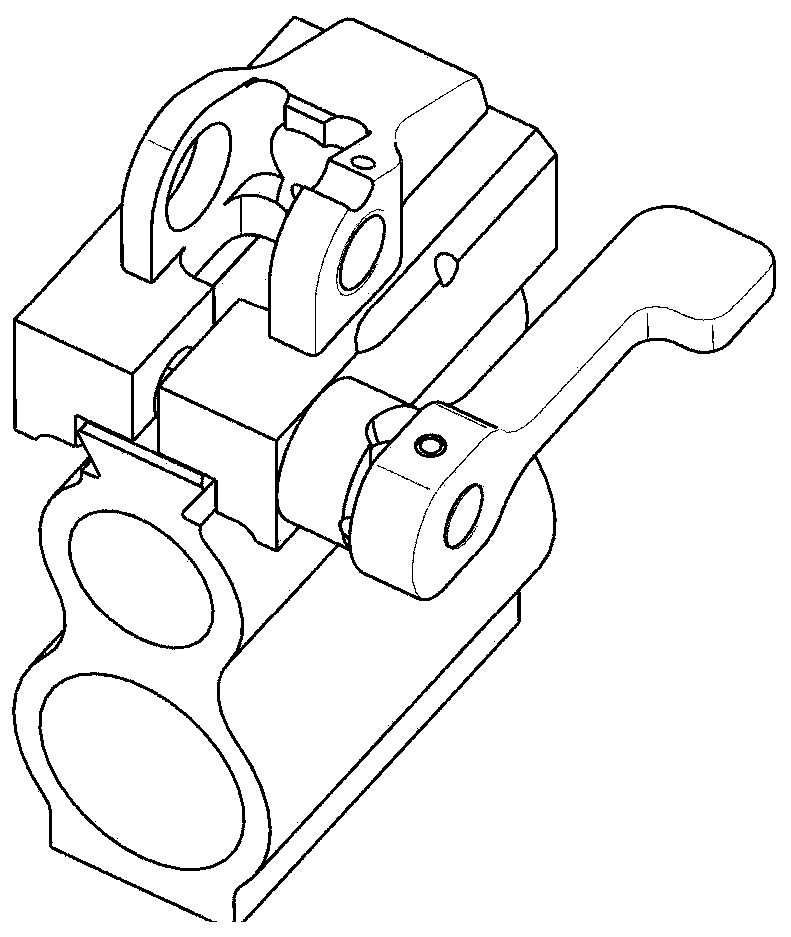

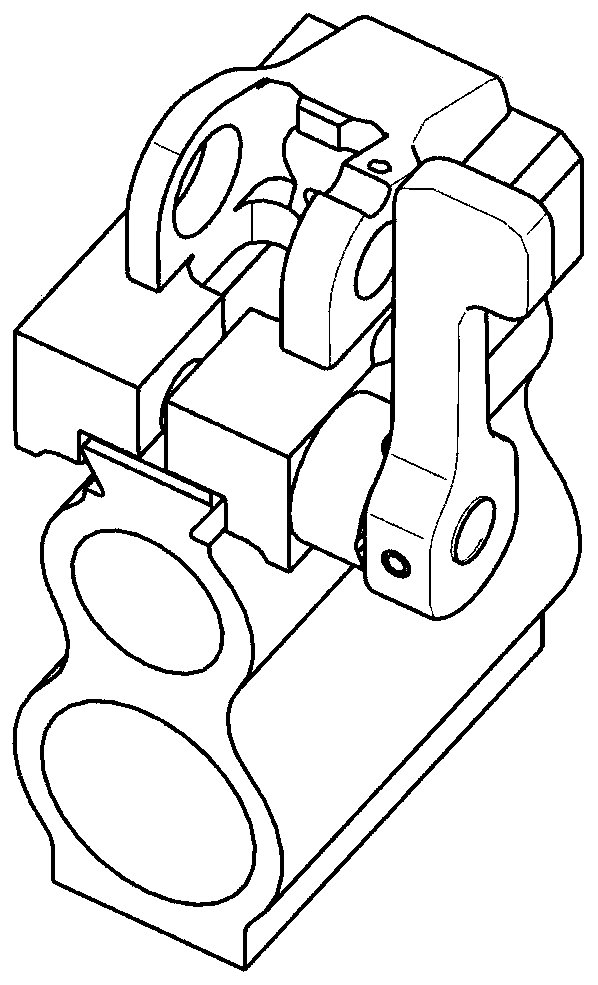

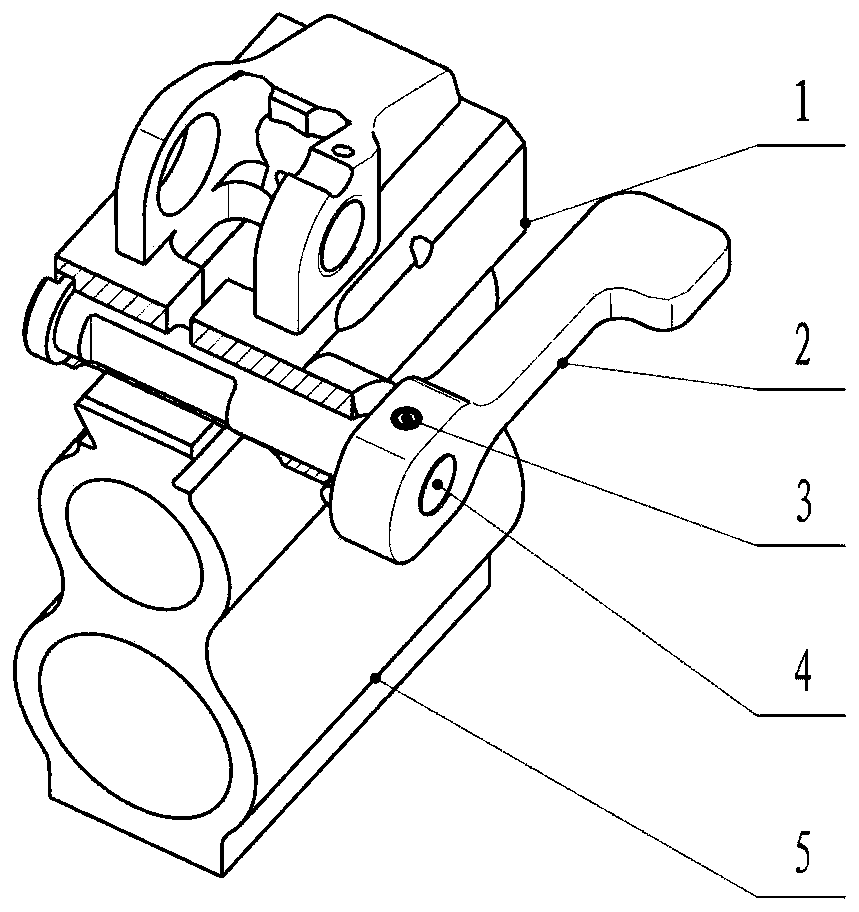

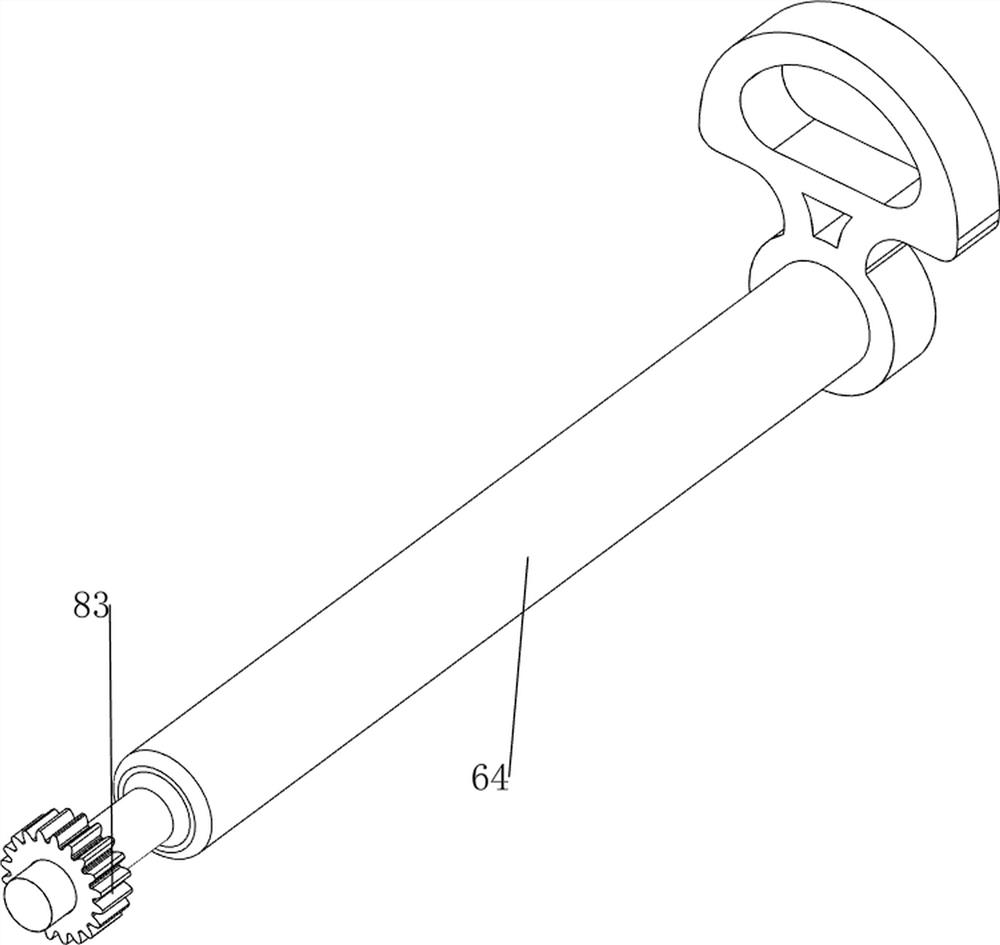

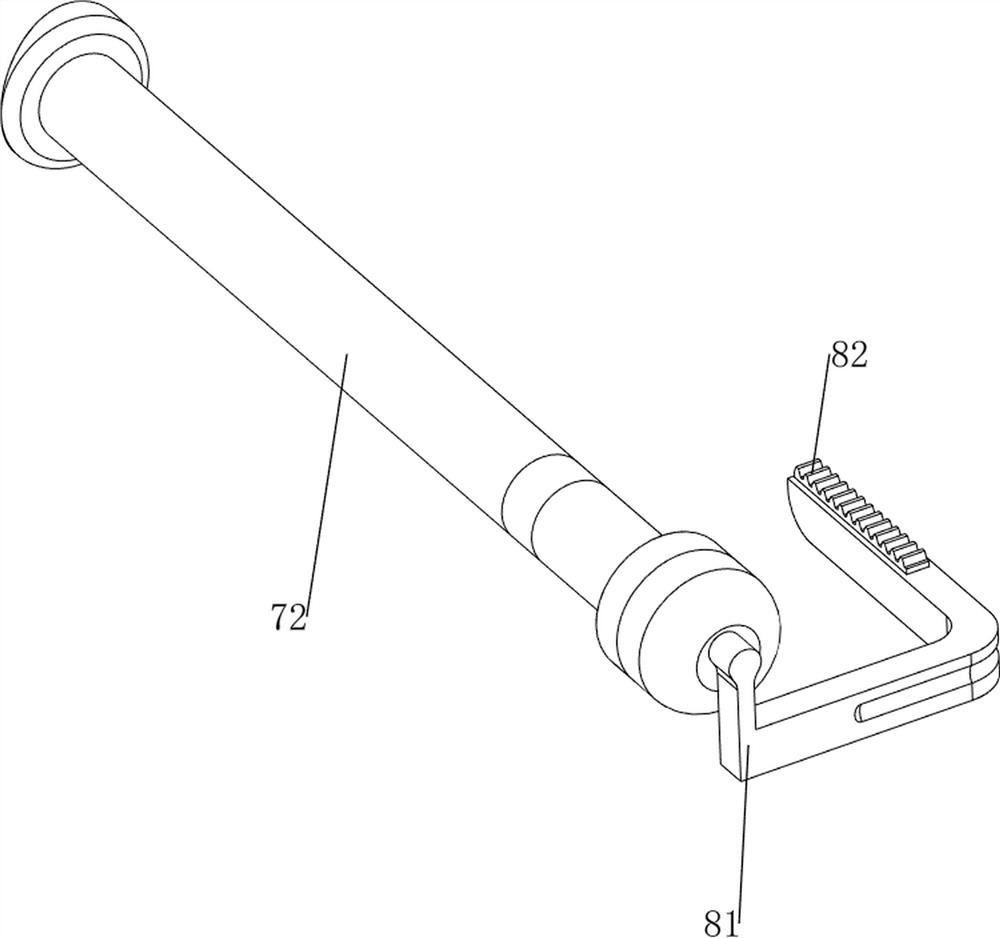

Quick limiting locking structure

PendingCN111551076AAchieve lockingAchieve separationSighting devicesButtsStructural engineeringMechanical engineering

The invention discloses a quick limiting locking structure. The quick limiting locking structure comprises a base, a dovetail seat, a limiting shaft and a handle, a groove opening is formed in the upper part of the base, the dovetail seat is arranged above the base and slidably connected with the base, the tail of the dovetail seat is provided with a longitudinal groove, one side of the tail of the dovetail seat is provided with a cylindrical part, the end face of the cylindrical part is provided with a spiral face, a limiting shaft is arranged at the tail of the dovetail seat in a sleeving mode, one end of the limiting shaft is in threaded connection with a handle, one side of the limiting shaft is provided with a notch, a boss is arranged on one side of the handle, the boss is matched with the spiral face of the dovetail seat, a lock pin is arranged on the handle in the radial direction and used for stopping rotation when the handle and the limiting shaft are connected, in a naturalstate, the handle is in a vertical state, the boss of the handle is located at the lowest position of the spiral face, the cylindrical face of the limiting shaft is separated from the groove opening of the base, the dovetail seat can be slidably separated from the base, when limiting locking is needed, the handle is rotated, the boss of the handle climbs from the low position of the spiral face tothe high position of the spiral face to lock the dovetail seat and the base, after the handle is rotated by 90 degrees, the boss of the handle is separated from the spiral face, and at the moment, the cylindrical face of the limiting shaft is superimposed with the groove opening of the base to limit sliding of the dovetail seat and the base.

Owner:CHONGQING JIANSHE IND GRP

Plate shearing machine with anti-slip structure for machining mechanical mold

PendingCN114505525AAchieve operational controlAchieve electrical connectionShearing machinesShearing machine accessoriesGear wheelMachining

The invention discloses a mechanical mold processing plate shearing machine with an anti-slip structure, which comprises a plate shearing machine, air cylinders are mounted on the left side and the right side of the upper surface of the plate shearing machine, mounting plates are mounted at the driving ends of the air cylinders, and a semi-arc gear I and a semi-arc gear II are respectively arranged at the upper part and the lower part of an inner cavity of the plate shearing machine. According to the plate shearing machine with the anti-slip structure for mechanical mold machining, a wire hose electrically connected to the left side of the outer wall of an arc cavity pipe can input electric energy to a plate fixing mechanism, an electric telescopic rod on the plate fixing mechanism is braked to operate, a telescopic rod connected to the driving end of the electric telescopic rod stretches out and draws back, and the plate fixing mechanism is driven to rotate; when the operating panel is cut, the rotating shaft and the fixing seat are pulled towards the mounting base plate, and meanwhile, the right clamping hand on the right side moves towards the left clamping hand, so that the operating panel between the two groups of clamping hands is clamped, the operating panel on the lower contact block is clamped and limited, and the stability of the operating panel in the cutting process is ensured.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

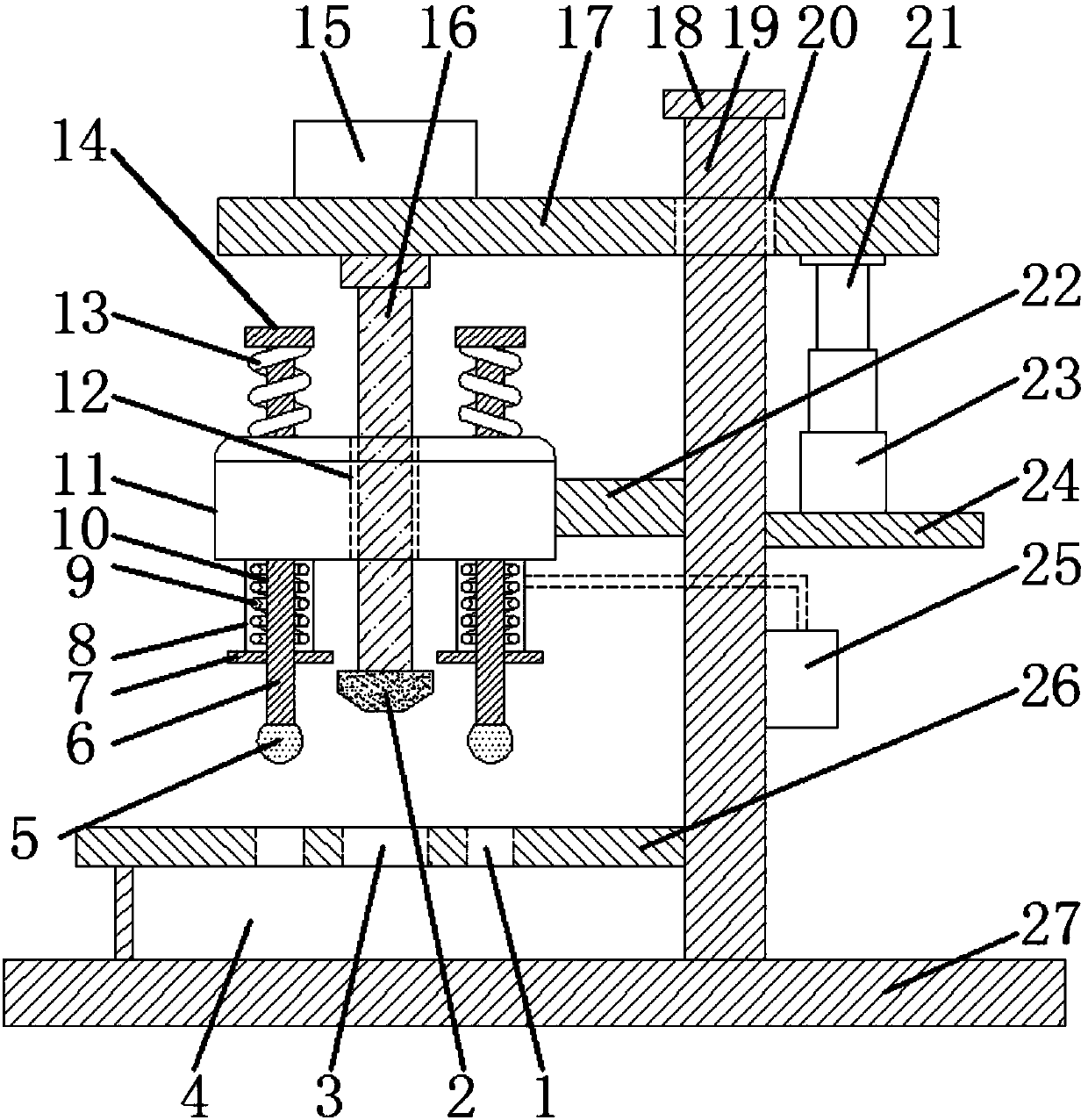

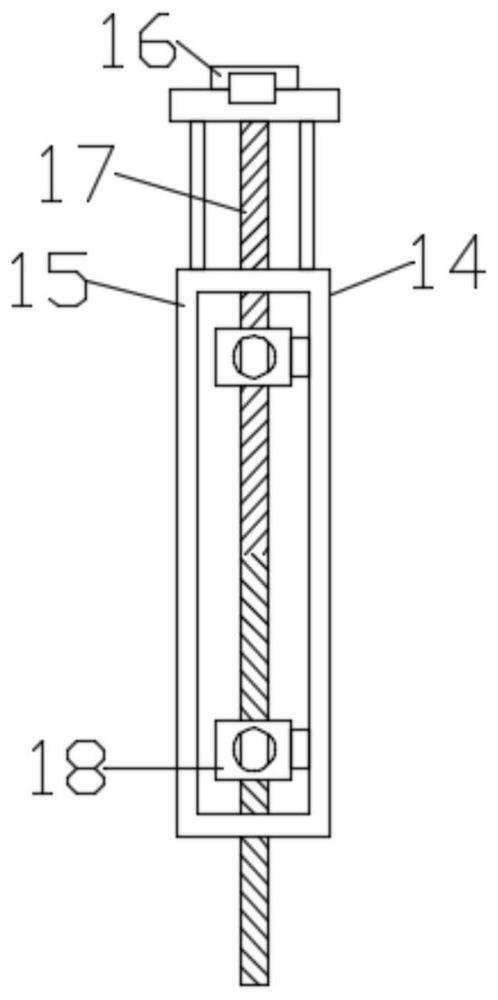

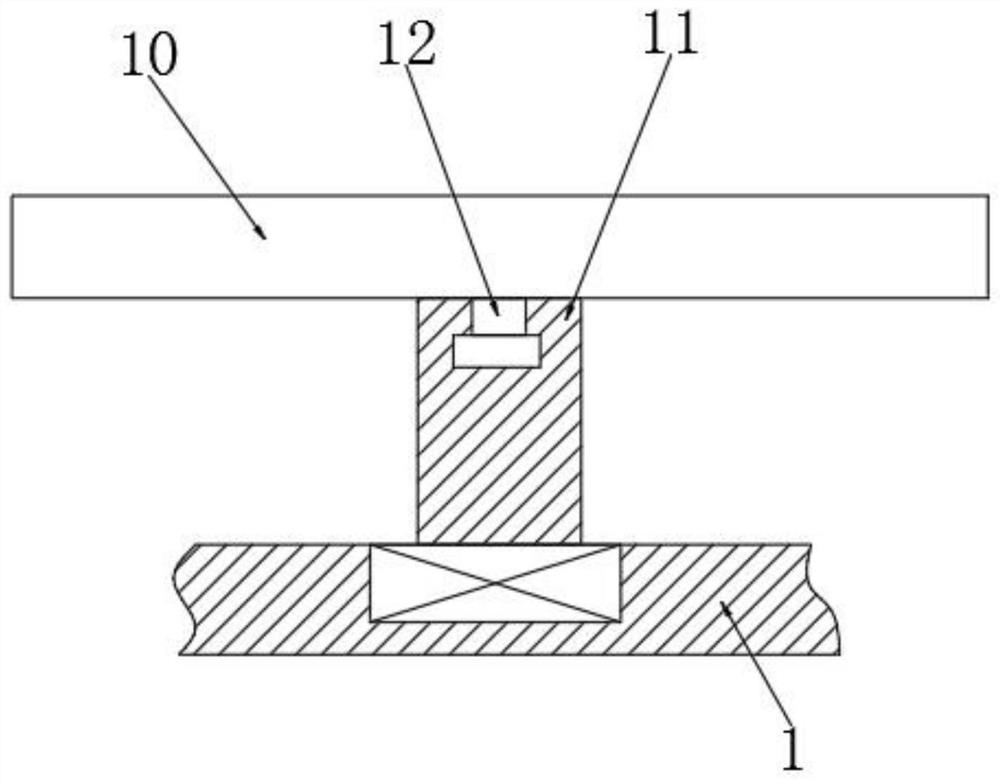

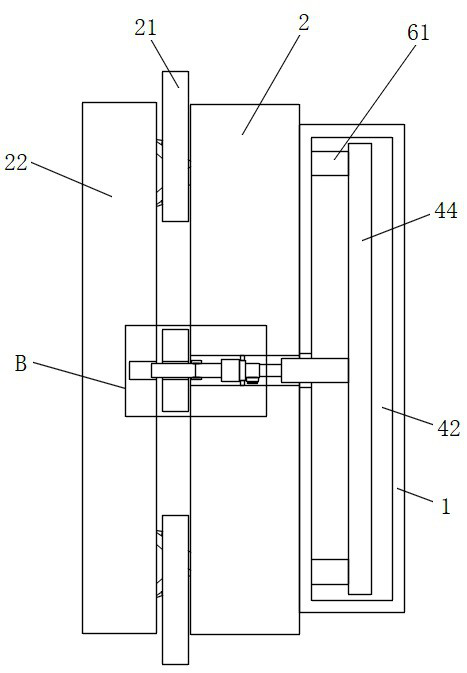

Positioning clamp for sewing machine head shell machining

InactiveCN112475990AHeight adjustableRealize clamping limitLarge fixed membersPositioning apparatusMachiningPhysics

The invention discloses a positioning clamp for sewing machine head shell machining, belongs to the technical field of sewing machines, and solves the problem that the machining difficulty of a shellis increased due to the fact that an existing device cannot adjust the position of a clamping plate mechanism. The positioning clamp is technically characterized by comprising a base and a stand column; the stand column is arranged above the base; an installation base is fixedly installed in the middle of the stand column; clamping assemblies used for clamping the shell are symmetrically arrangedon the two sides of the installation base; the installation base is fixedly connected with the clamping assemblies; and a position adjusting assembly used for adjusting the height of the stand columnis arranged between the stand column and the base. According to the embodiment of the invention, the position adjusting assembly is arranged, the height of the clamping assemblies is adjusted throughthe arrangement of the position adjusting assembly, shells can be conveniently clamped in different environments, the shell machining efficiency is improved, and meanwhile, the shells of different shapes are clamped and limited through the arrangement of a swing assembly.

Owner:WUJIANG ZHENYU SEWING EQUIP

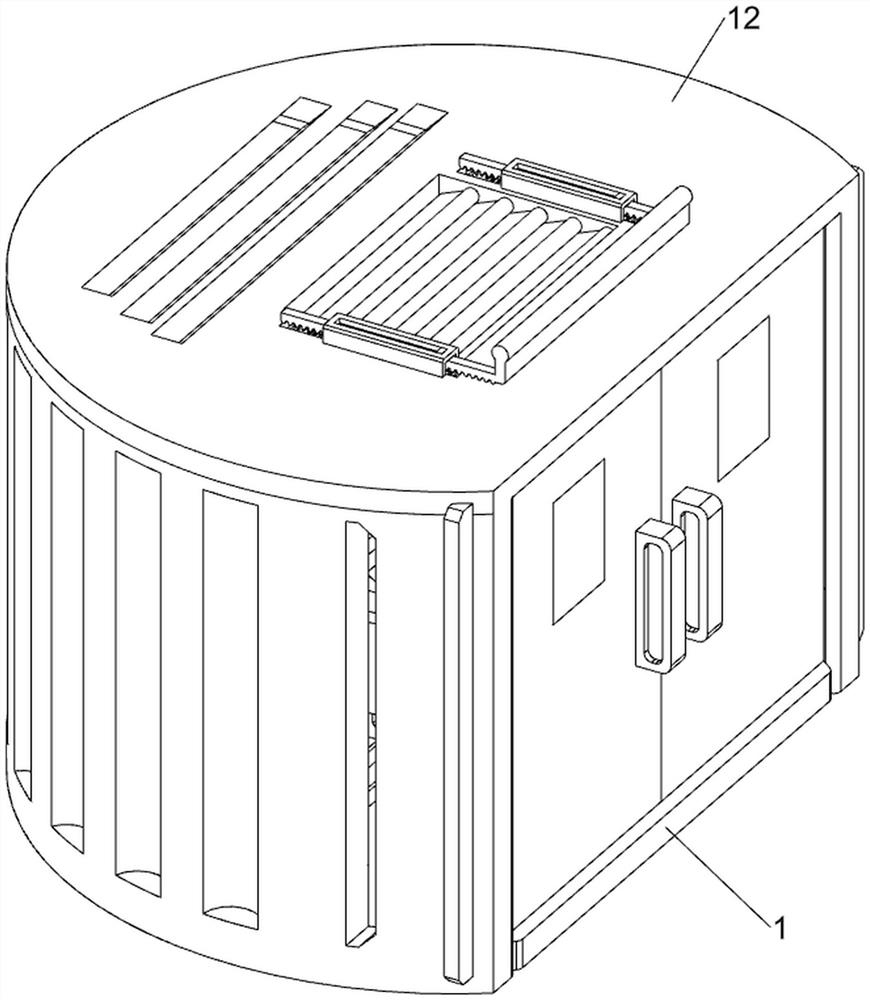

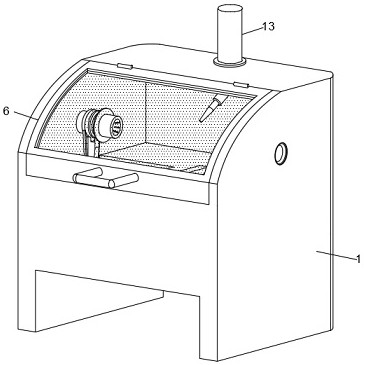

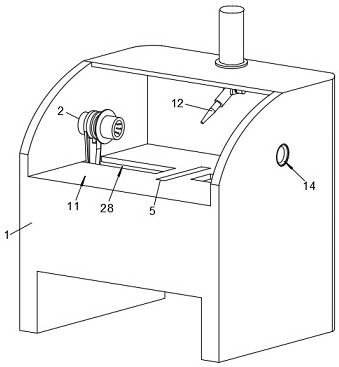

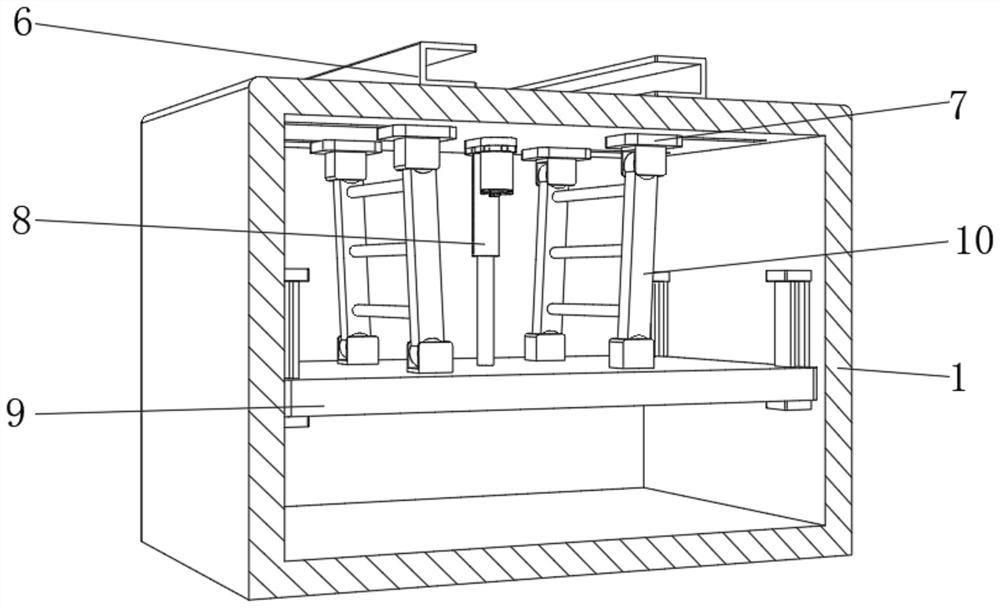

Industrial automatic electric arc welding workbench

InactiveCN114833505AEasy to operateImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryEngineering

The invention provides an industrial automatic electric arc welding workbench. The industrial automatic electric arc welding workbench comprises a shell, a machining cavity is formed in the shell, a welding head is mounted in the machining cavity through an adjusting assembly, a protective door is mounted at an opening of the machining cavity, a rotating assembly is mounted in the machining cavity, and the rotating assembly comprises two positioning pipes; the two positioning pipes are symmetrically installed in the machining cavity, feeding ports matched with the positioning pipes are formed in the outer side wall of the shell, the positioning pipes are sleeved with limiting covers rotationally connected with the positioning pipes, supporting plates are fixedly installed at the bottoms of the limiting covers, limiting sliding grooves are formed in the shell, and the supporting plates penetrate through the limiting sliding grooves. And a bidirectional driving motor is fixedly mounted in the shell. The industrial automatic electric arc welding workbench has the advantages of being convenient and fast to operate, high in working efficiency and high in safety.

Owner:江苏梦尧智能制造有限公司

Machining equipment for air conditioner metal plate underframe

ActiveCN114871330AEasy to typeEasy to operateMetal-working feeding devicesPositioning devicesHydraulic cylinderPunching

The invention relates to the technical field of air conditioner bottom frame machining, in particular to air conditioner metal plate bottom frame machining equipment which comprises a machining table, a steel belt is arranged in the machining table, a punching mechanism used for punching the steel belt is installed on the machining table, and the punching mechanism comprises a U-shaped frame fixedly connected to the top of the machining table; when a sliding block is located in a vertical groove, a telescopic hydraulic cylinder drives a punching block to rapidly move downwards to punch a steel belt, a rotating ring is pushed to drive the sliding block to rotate, so that the sliding block moves into an arc-shaped groove, a rotating rod is shaken to drive a rotating gear to rotate, and the steel belt is punched. And when the rotating gear rotates to drive the rack and the sliding plate to move to the other fixing plug pin, and the telescopic hydraulic cylinder drives the punching block to quickly move downwards, the punching block can drive the punching column to move downwards for punching, so that holes of different specifications can be conveniently punched in the steel belt, the punching head does not need to be replaced, and the operation is simple.

Owner:江苏江平新环境科技有限公司

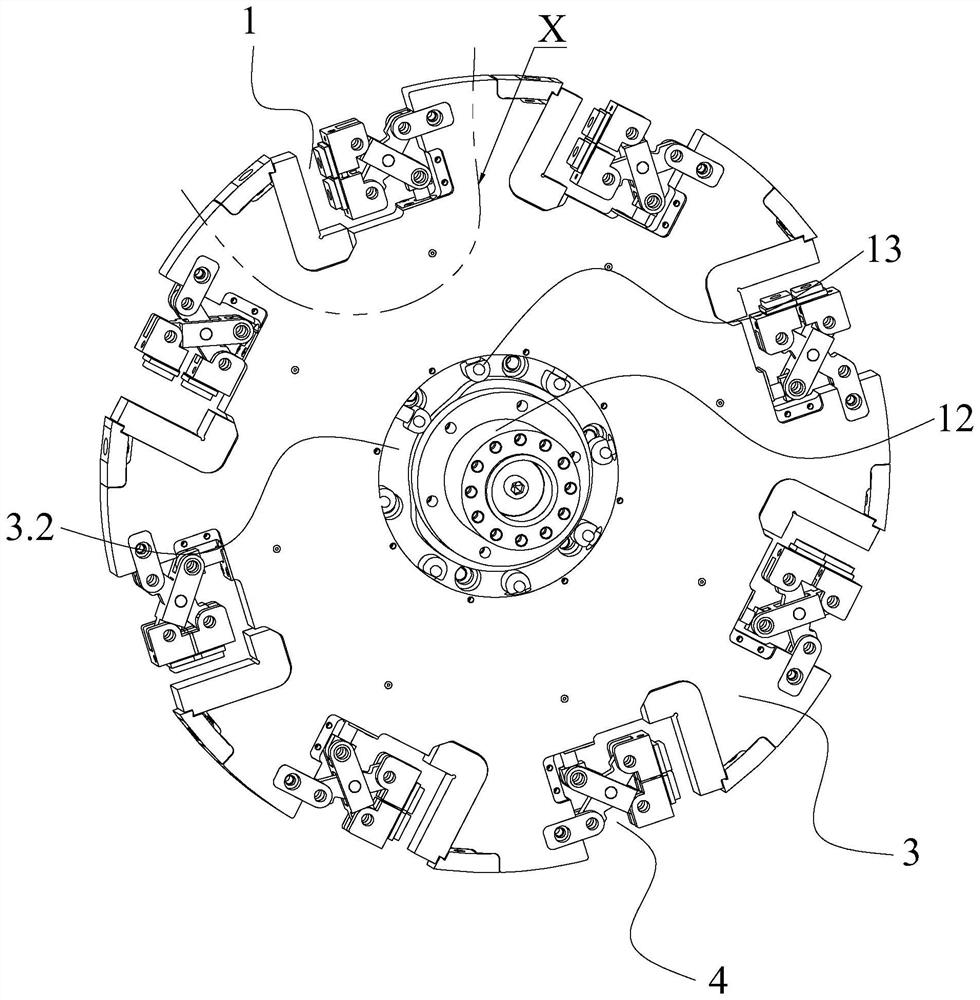

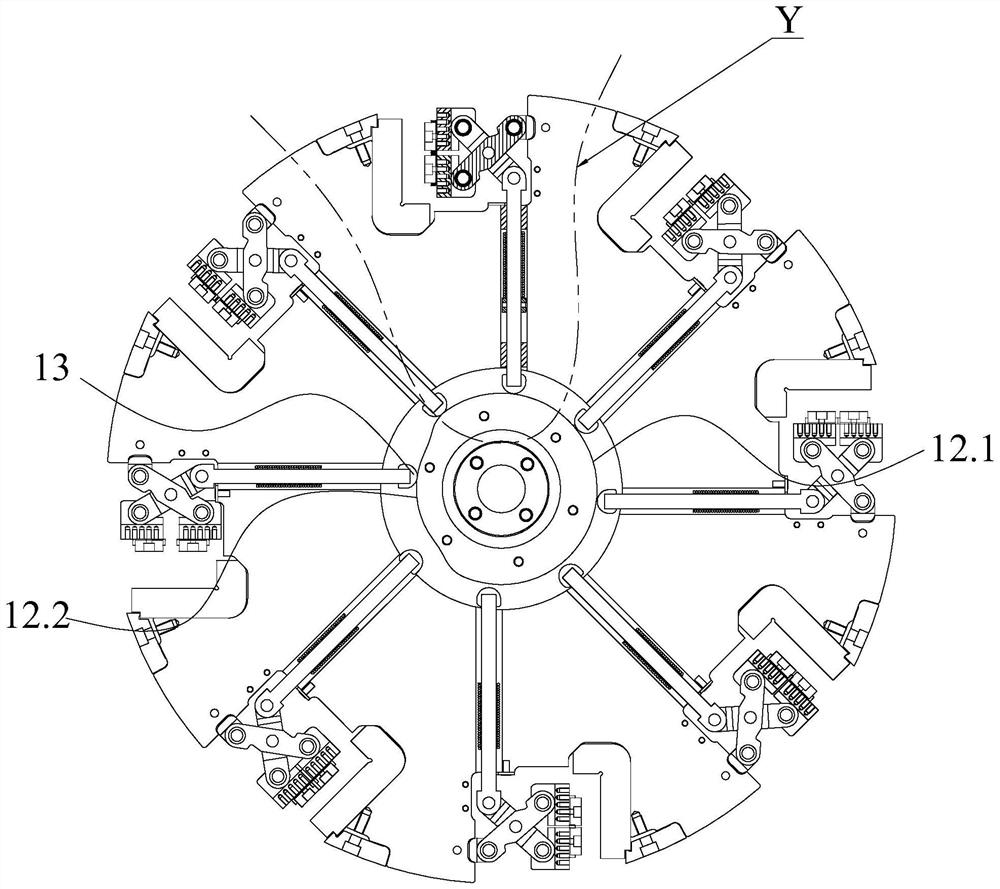

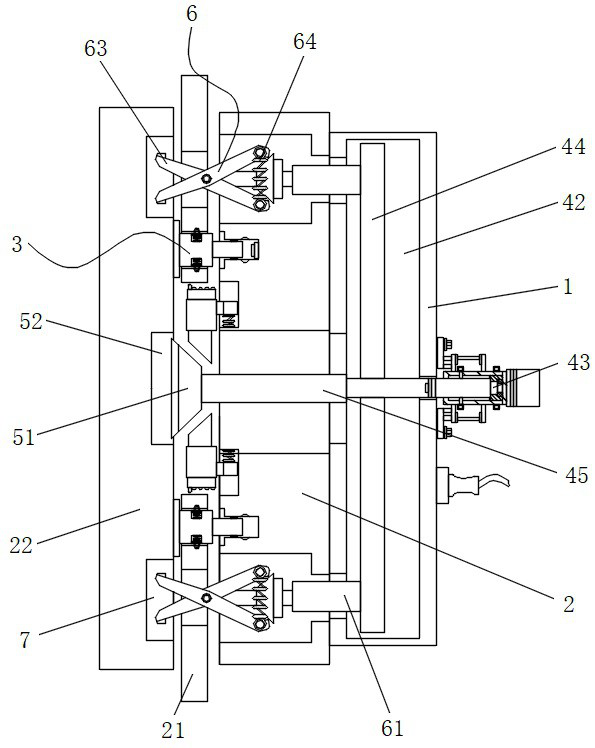

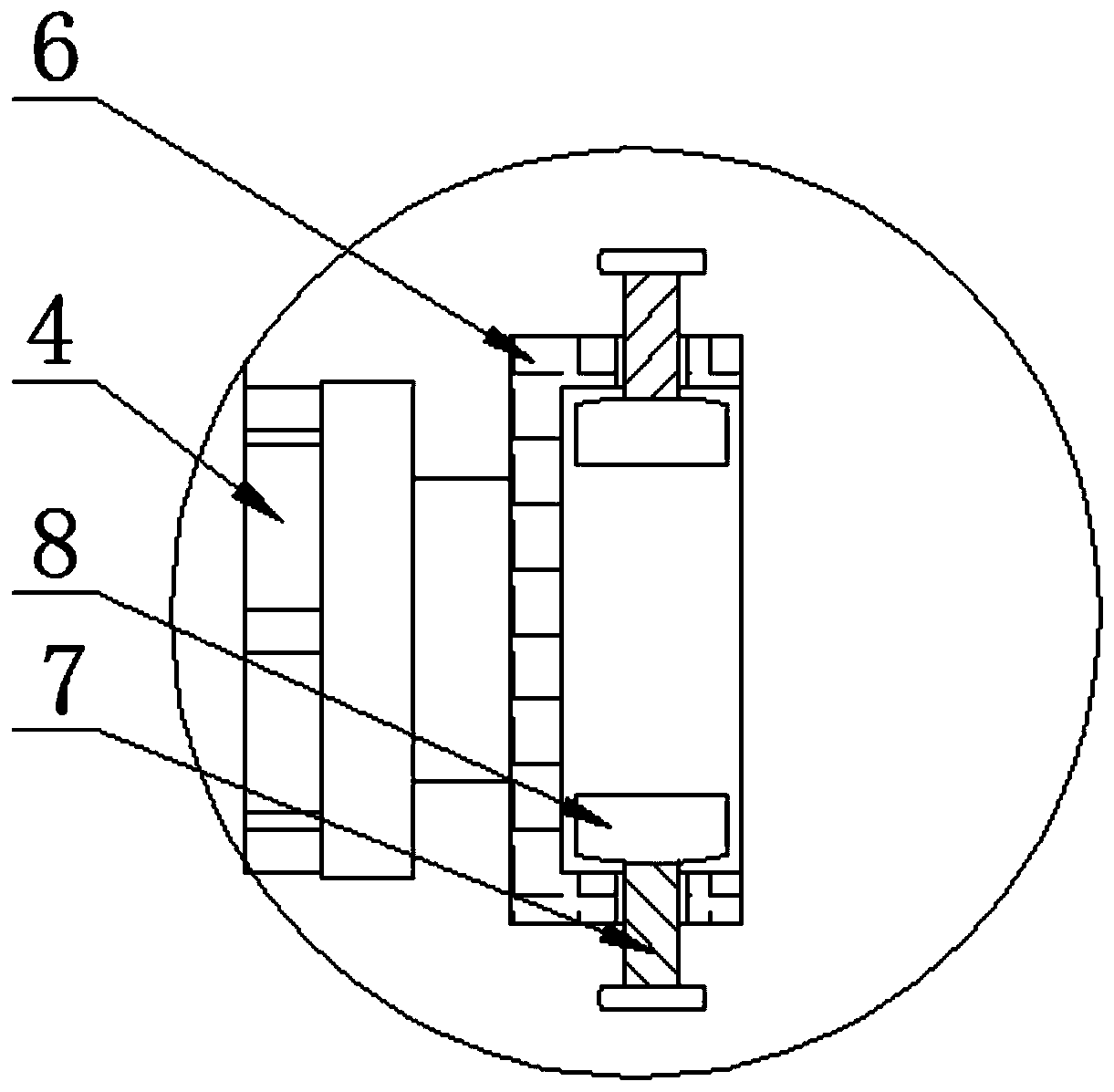

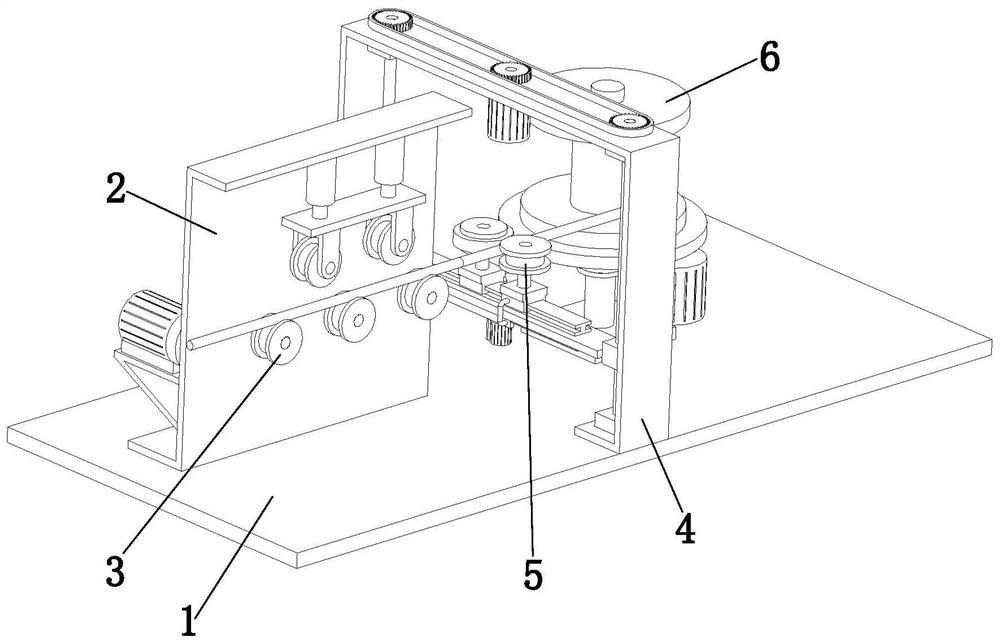

Double-end-face grinding machine

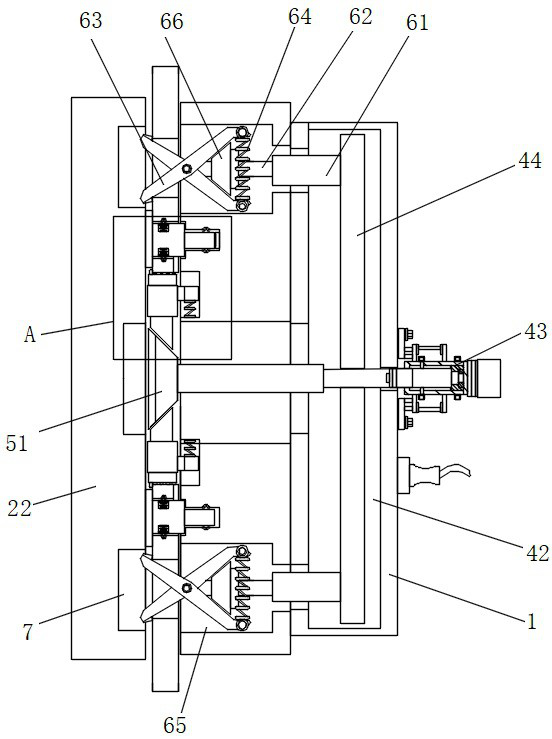

ActiveCN114850995AAchieve clampingAchieve releaseGrinding carriagesGrinding feedersElectric machineryEngineering

The invention provides a double-end-face grinding machine which comprises a machine base. Two grinding discs, a feeding assembly, a feeding rotary disc and a motor for driving the feeding rotary disc to rotate are installed on the machine base. A plurality of mounting grooves are formed in the circumferential outer wall of the feeding rotary disc in an inward concave mode, and pressing assemblies are assembled on the sides, in the width direction, of the interiors of the mounting grooves and can stretch out and draw back in the width direction of the mounting grooves; a workpiece positioning channel with the adjustable width is formed between the pressing face of the pressing assembly and the other side of the installation groove in the width direction. The feeding rotary disc is further connected with a driving assembly, and when the motor drives the feeding rotary disc to rotate to different set positions in the circumferential direction, the driving assembly is used for driving the pressing assembly to stretch out or retract, so that the workpieces are clamped or loosened. According to the double-end-face grinding machine, the grinding channel used for conveying workpieces on the feeding mechanism to the position between the grinding discs one by one is additionally arranged between the two grinding discs, and clamping of the workpieces is stable and efficient.

Owner:宁波邦一机械科技有限公司

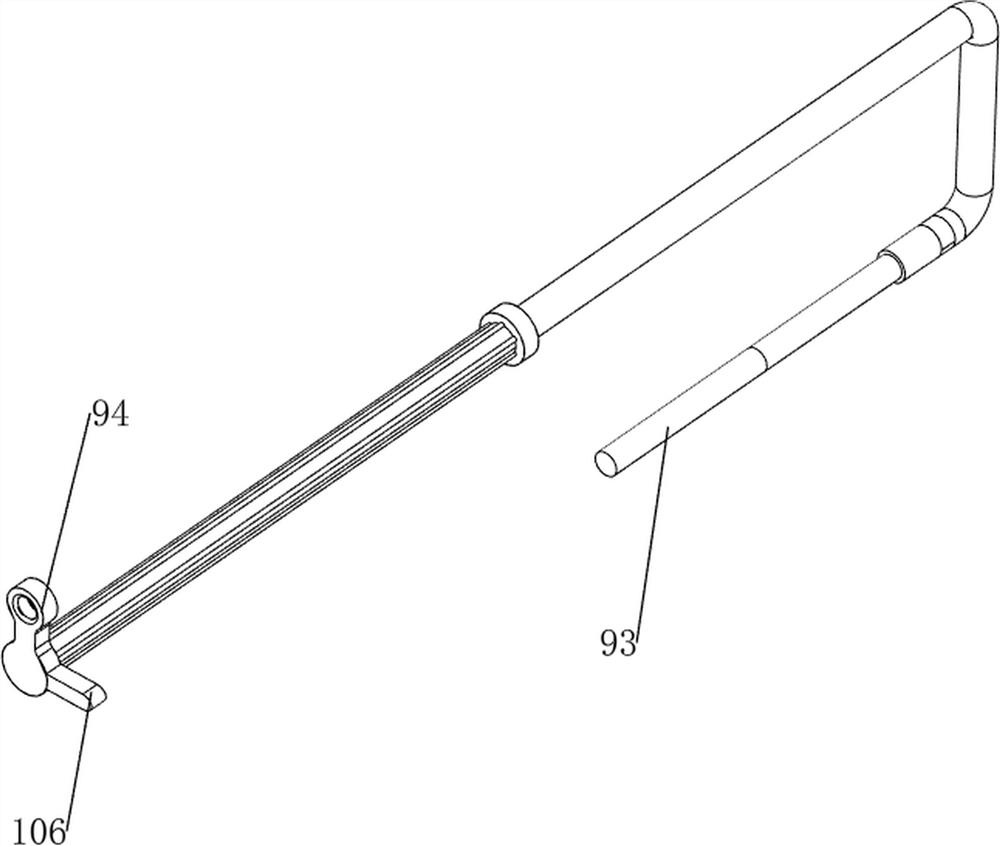

Skin perception examination device for neurology department

PendingCN113069075ATurn and fold to achieveRealize storageDiagnostic recording/measuringSensorsPhysical medicine and rehabilitationNeurology department

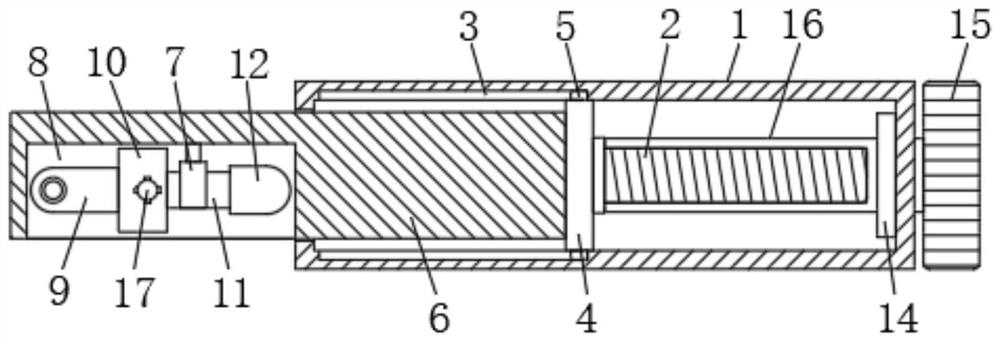

The invention discloses a skin perception examination device for the neurology department, and relates to the technical field of medical instruments. The skin perception examination device for the neurology department comprises an outer cylinder and an extension cylinder, an adjusting mechanism is arranged in the outer cylinder, the outer cylinder and the extension cylinder are connected through the adjusting mechanism, a rotary folding mechanism is arranged at one end of the extension cylinder, the rotary folding mechanism comprises a storage groove formed in the extension cylinder and a damping rotating shaft installed on one side of the interior of the storage groove, the damping rotating shaft is sleeved with a rotating rod, and the bottom end of the rotating rod is connected with a contact through a connecting assembly. Through arrangement of the rotating folding mechanism, rotating folding of the contact can be achieved, so that storage of the contact is achieved, the occupied space of the device is effectively reduced, the storage space of the device is greatly saved, so that the device is convenient to store, the device is more portable, the device is convenient to use, and the practicability of the device is improved.

Owner:THE SECOND HOSPITAL OF HEBEI MEDICAL UNIV

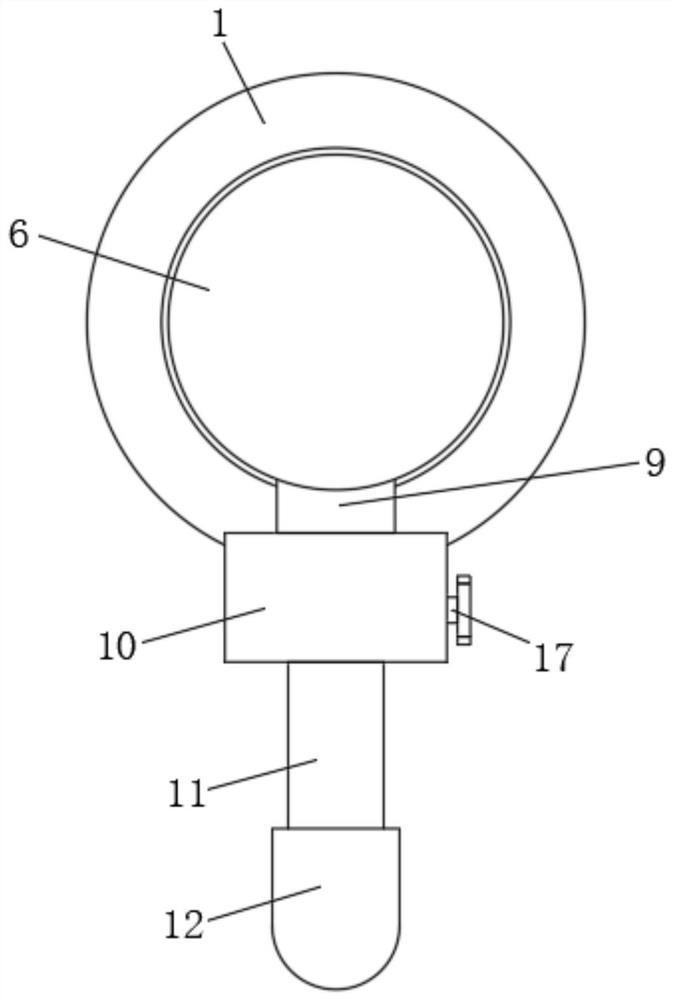

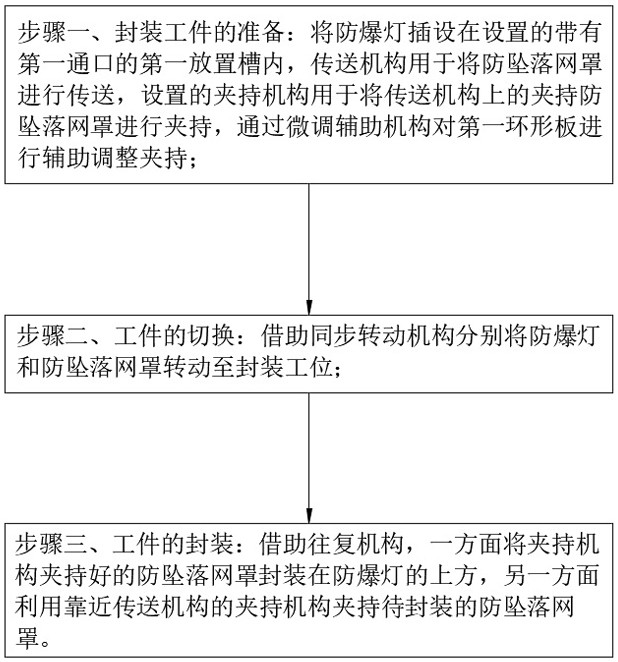

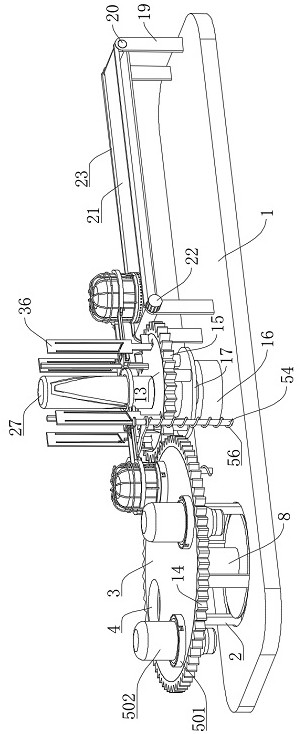

Optical device production, processing and packaging device and packaging method thereof

InactiveCN114755771AEasy to holdEasy to packCoupling light guidesMechanical engineeringElectrical and Electronics engineering

The invention relates to the technical field of optical device packaging, in particular to an optical device producing, processing and packaging device and a packaging method thereof.The optical device producing, processing and packaging device comprises a bottom plate and a second circular plate, the top of the bottom plate is slidably connected with four sliding blocks, and the tops of the four sliding blocks are jointly and fixedly connected with a first circular plate; four first placement grooves are formed in the top of the first circular plate in a circumferential array mode, first through openings are formed in the bottoms in the first placement grooves, explosion-proof lamps are inserted into the first placement grooves and are composed of lamp holders and bulbs which are fixedly connected with one another, first annular grooves are formed in the tops of the lamp holders, and first through openings are formed in the bottoms in the first placement grooves; second through openings are symmetrically formed in the side wall of the first annular groove. The reciprocating mechanism drives the mounting block to move downwards, the mounting block moving downwards close to the packaging station can insert the anti-falling net cover into the first annular groove in the top of the lamp holder through the clamping mechanism, and therefore one-time packaging of the explosion-proof lamp and the anti-falling net cover is completed, manual packaging is not needed in the whole process, and more automation is achieved.

Owner:深圳市兆捷科技有限公司

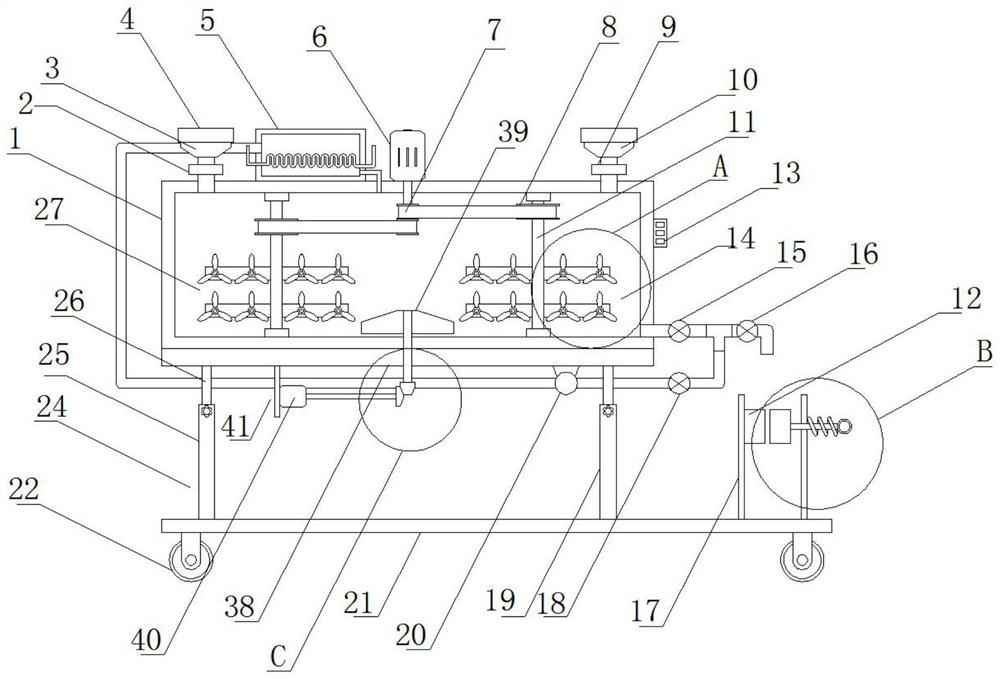

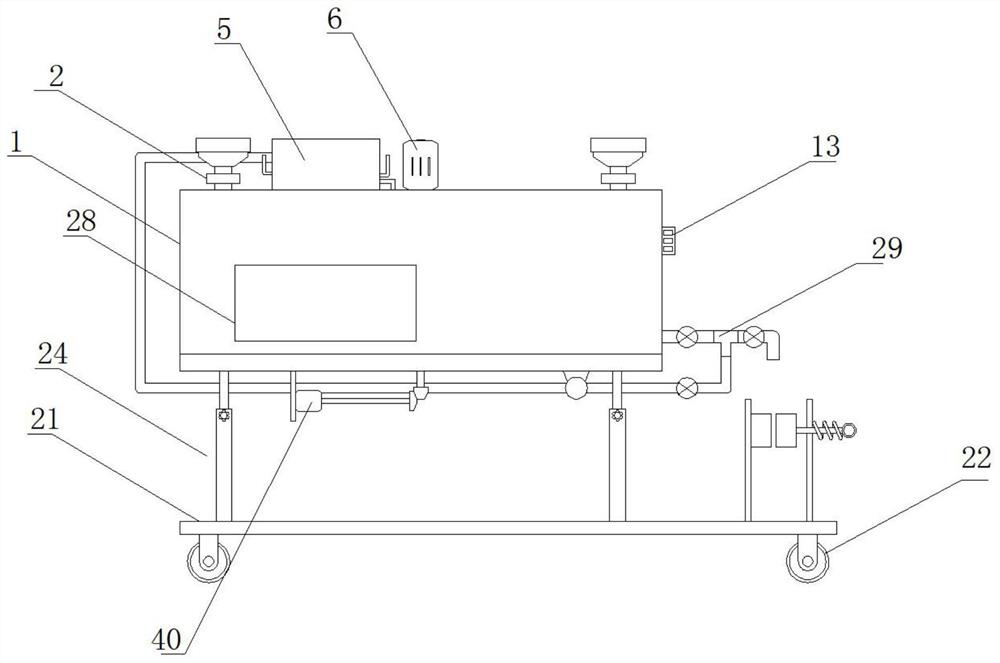

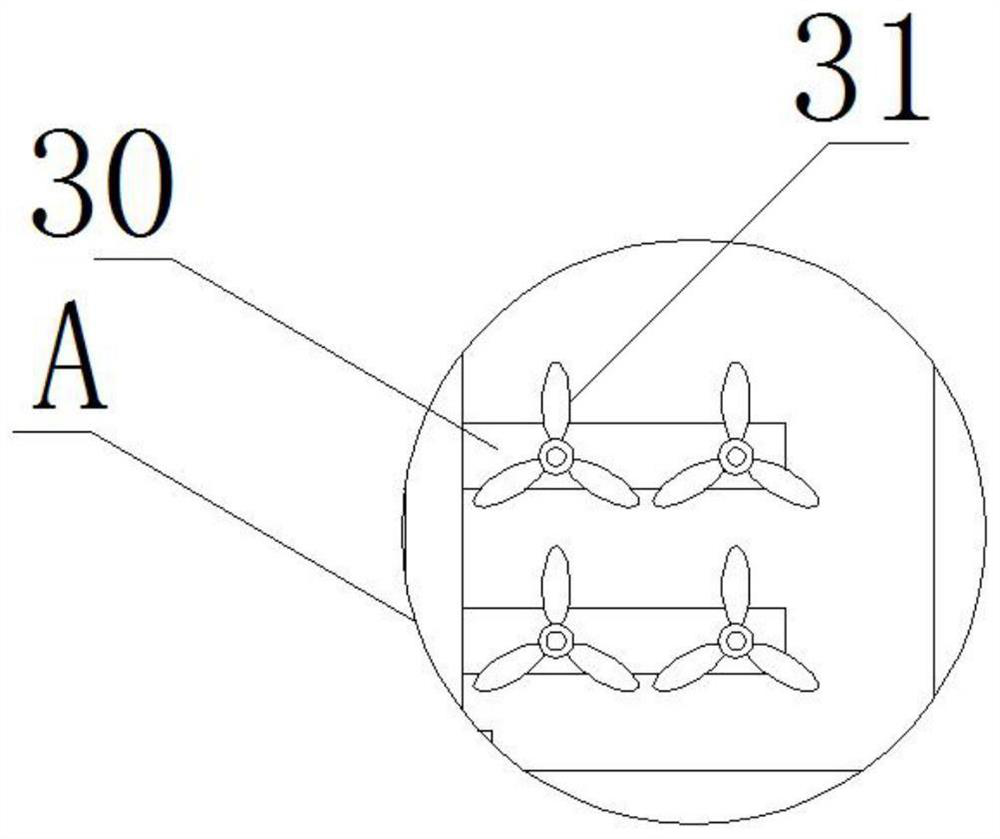

Uniform mixing device for DNA extraction

ActiveCN112159805AAchieve mixingImprove the mixing effectRotary stirring mixersTransportation and packagingElectric machineryDNA extraction

The invention discloses a uniform mixing device for DNA extraction. The uniform mixing device comprises a first motor, a water pump, uniform mixing blades, a temperature adjusting box and a uniform mixing box; the first motor rotates to drive a first belt wheel to rotate, so that a second belt wheel is driven to rotate, stirring blades on a stirring rotating shaft are driven to rotate, and a solution in the uniform mixing box is uniformly mixed; the uniform mixing blades rotate together in the rotating process of the stirring blades, so that the effect of uniformly mixing a solution in the uniform mixing box is improved; the temperature of the solution in the temperature adjusting box is adjusted by utilizing a heat conduction medium through a heat conduction tube, the solution in the temperature adjusting box further enters the uniform mixing box through the liquid guide tube, and manual uniform mixing of detection personnel is not needed, so that the working intensity of a detectionpersonnel is highly lowered; after uniform mixing is completed, containers such as test tubes and the like are placed between a first clamping plate and a second clamping plate, the second clamping plate moves towards the first clamping plate under the action of the elastic force of a spring, and therefore the containers such as the test tubes and the like are clamped and limited, and DNA extraction by the detection personnel is facilitated.

Owner:JILIN UNIV

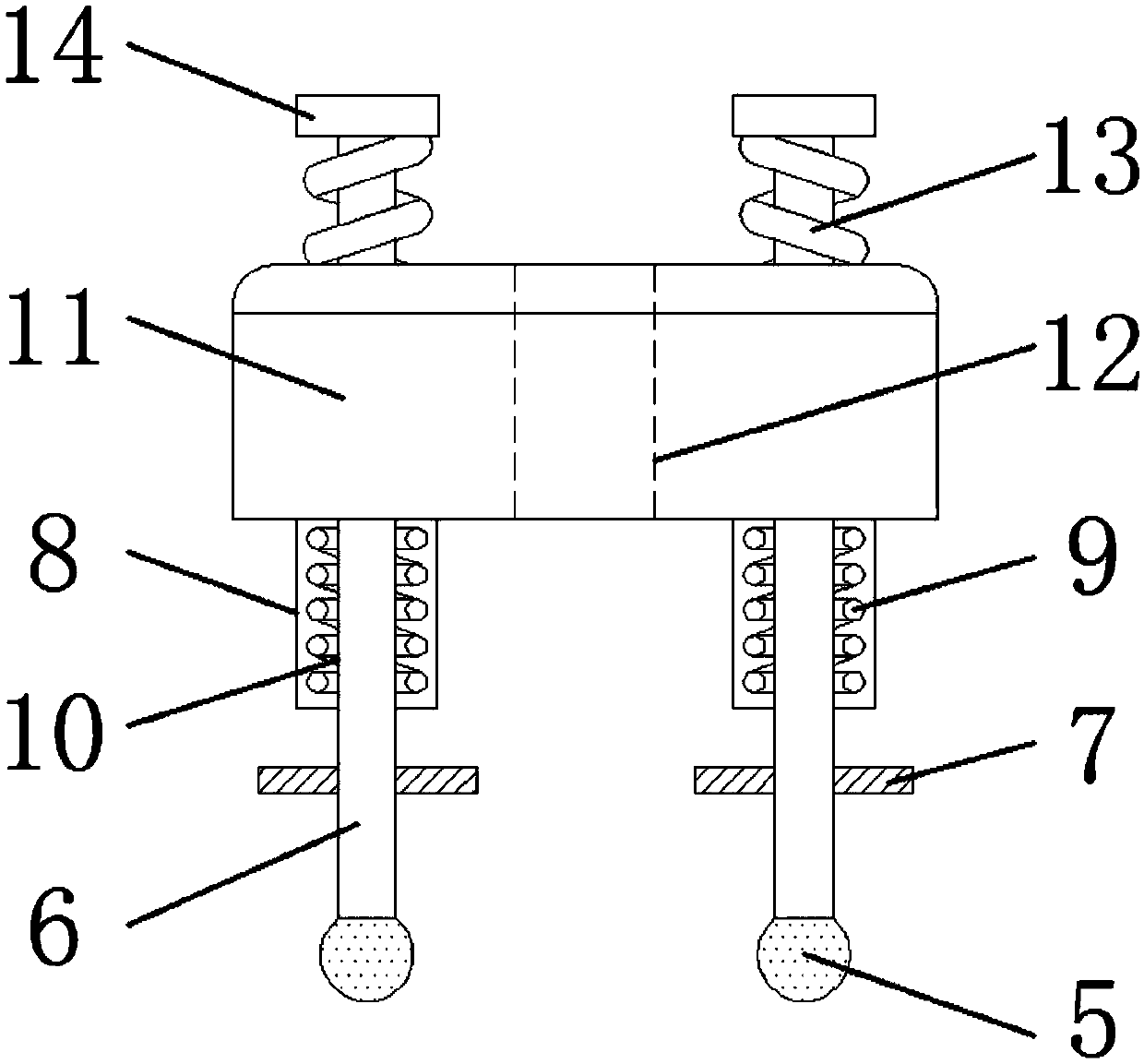

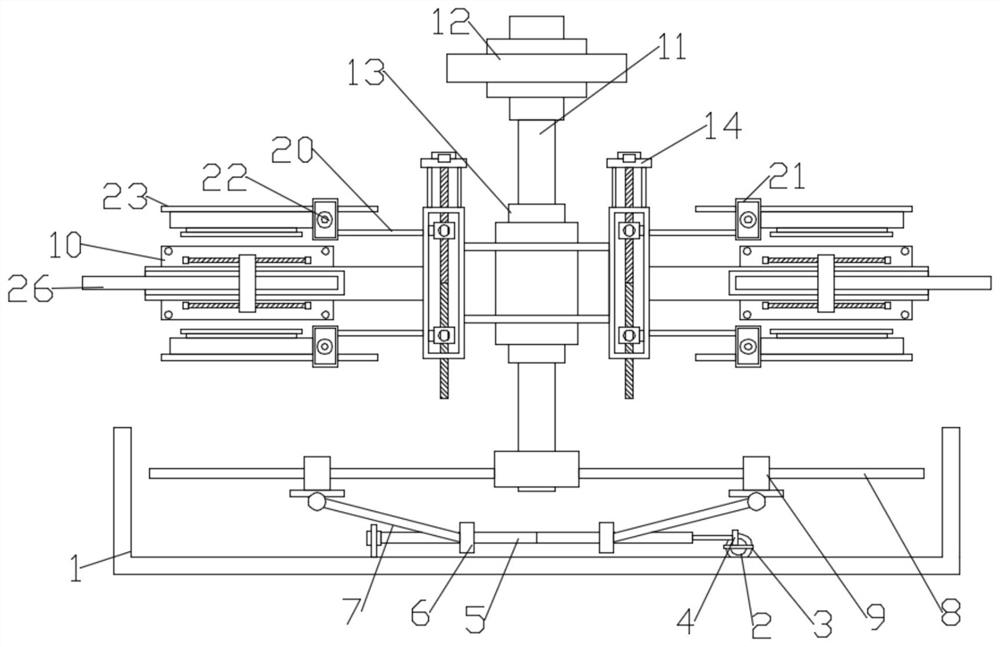

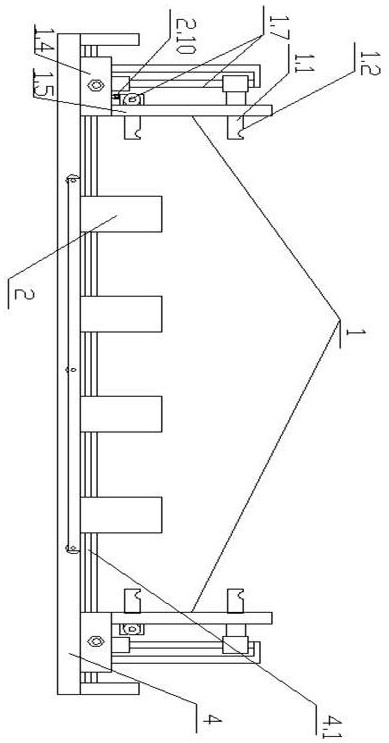

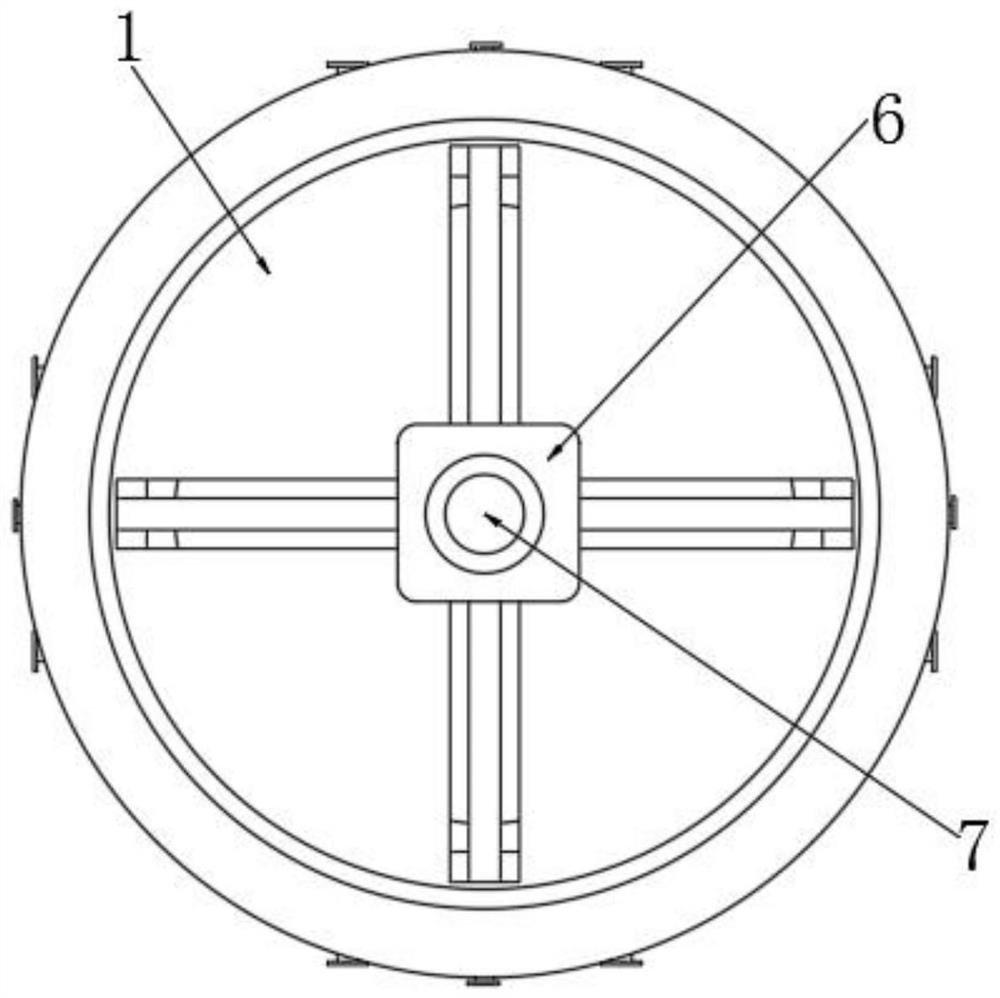

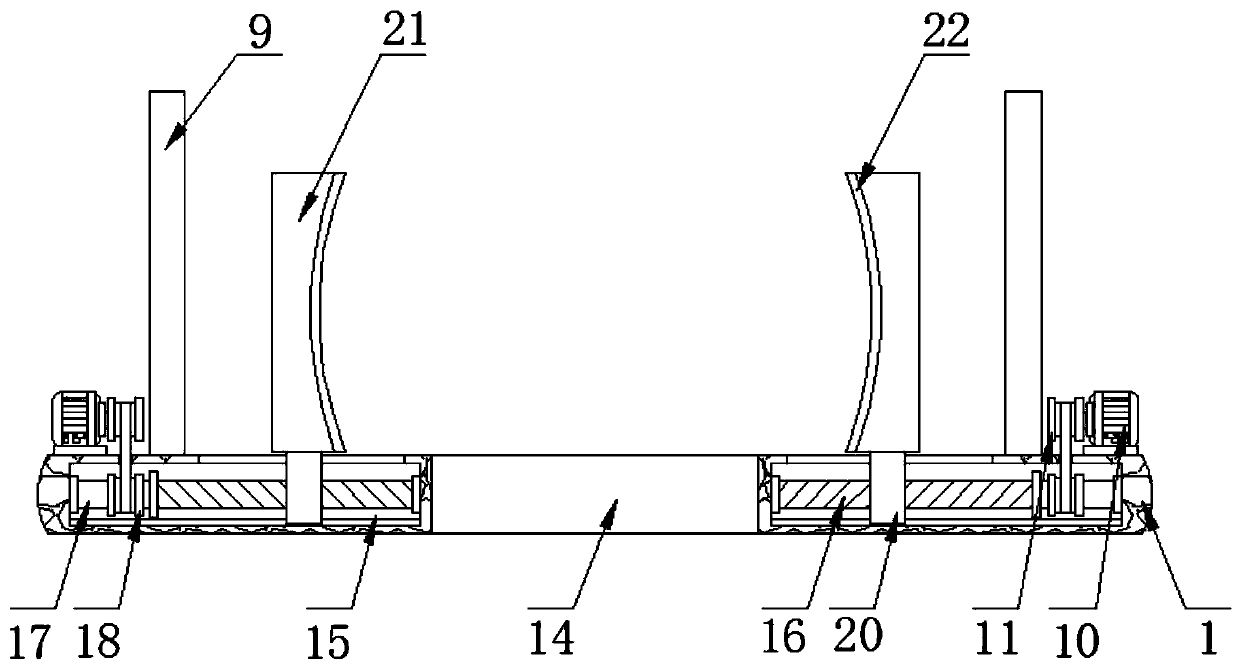

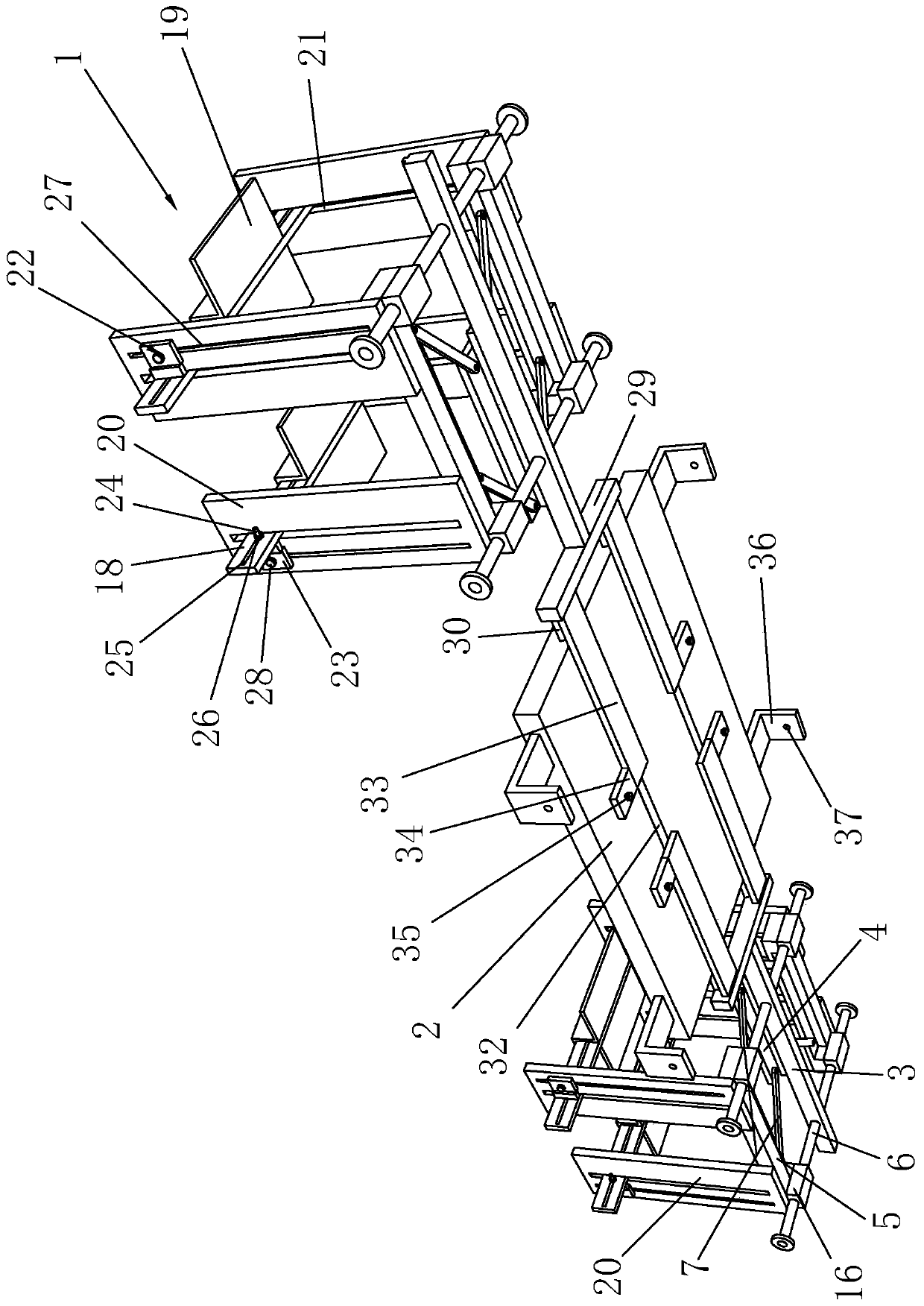

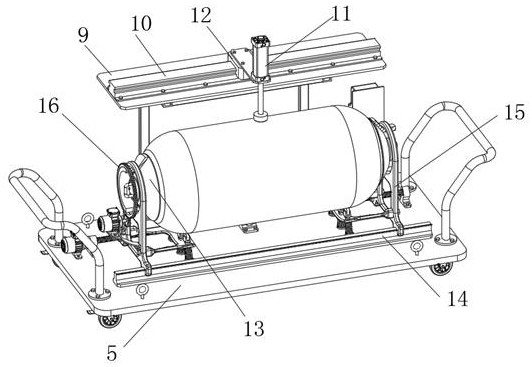

Tower crane boom welding device

PendingCN114029673AEasy clampingRealize clamping limitWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringTower crane

The invention discloses a tower crane boom welding device which comprises mounting and clamping mechanisms, clamping mechanisms and an automatic conveying mechanism, and is characterized in that a mounting base is mounted on the ground, a sliding assembly is arranged on the mounting base, the mounting and clamping mechanisms moving on the sliding assembly are arranged at the two ends of the sliding assembly, the two mounting and clamping mechanisms are used for clamping the ends of a chord member, the clamping mechanisms are arranged on the mounting base, the two ends of the chord member are clamped through the clamping mechanisms, the automatic conveying mechanism is arranged on one side of the mounting base, and the chord member is automatically mounted and dismounted through the automatic conveying mechanism. The chord member of the lifting arm can be conveniently clamped, meanwhile, clamping and limiting of the chord member are achieved in an automatic clamping mode, and bending deformation of the middle section of the chord member during welding is prevented. Meanwhile, automatic clamping and unloading are conducted, so that the clamping speed and the disassembling speed are high, the machining efficiency of the lifting arm is improved, and the production process tends to be simplified.

Owner:临澧金华天机械制造有限公司

Skipping rope handle coloring device for sporting goods processing

The invention relates to a paint brushing device, in particular to a skipping rope handle coloring device for sporting goods processing. According to the technical purpose, the skipping rope handle coloring device for sporting goods processing can automatically paint handles. A skipping rope handle coloring device for sports goods processing comprises a supporting plate, a first supporting frame, a rotating frame, first rubber, a motor, a manual rotating mechanism and a clamping mechanism, the first supporting frame is arranged on one side of the top of the supporting plate, the rotating frame is rotationally arranged on the first supporting frame, the first rubber is arranged in the rotating frame, the motor is arranged on the first supporting frame, and the manual rotating mechanism is arranged on the motor. A motor output shaft is connected with the rotating frame, a manual rotating mechanism is arranged in the middle of one side of the top of the supporting plate, and a clamping mechanism is arranged on the first supporting frame. A user places a handle in the rotating frame, and through cooperation of the movable rods on the two sides, the handle can be clamped and limited, so that when the handle is painted, the handle does not need to be manually taken.

Owner:韦东美

A center hole grinding device of an automobile inner star wheel with magnetic suction positioning

ActiveCN107891322BEasy to adjustPrevent slidingGrinding carriagesRevolution surface grinding machinesRotational axisElectric machinery

The invention discloses a magnetic attraction locating automobile internal star wheel center hole polishing device which comprises stop blocks, an electromagnetic guide block, a rotating shaft, a telescopic rod, a base and an internal star wheel; the upper end of the base is fixedly connected with an upright column; the top end of the upright column is fixedly connected with a limiting stopper; the part, below the limiting stopper, of the upright column is sleeved with an upper beam plate; a motor is arranged at the part, on one side of the upright column, of the top end of the upper beam plate; the bottom end of the motor is connected with the rotating shaft; a grinding sheet is arranged at the bottom end of the rotating shaft; the middle part of the upright column is connected with a fixing bracket; the electromagnetic guide block is arranged on the fixing bracket; electromagnet sleeves are arranged at the bottom of the electromagnetic guide block; inner guide cylinders are arrangedin the electromagnet sleeves; a coil is wound between each inner guide cylinder and the corresponding electromagnet sleeve; and iron-core rods penetrate through the inner guide cylinders. Height adjustment is realized when the grinding sheet carries outer rotating polishing; ball way limiting balls at the bottom ends of the iron-core rods are clamped into ball ways of the internal star wheel, so that clamping and limiting on the internal star wheel are realized, and the stability is good; and operation is convenient and quick, and no manual clamping or fixing is required.

Owner:安徽赢廷智能装备有限公司

Tank bottom supporting structure for tank transportation and working method of tank bottom supporting structure

The invention discloses a tank bottom supporting structure for tank transportation. The structure comprises a mounting disc and limiting mechanisms, wherein a plurality of sliding grooves are formed in the top of the mounting disc at equal angles. A tank body is placed on a rotary disc, a servo motor works, a speed reducer adjusts the speed to drive a main bevel gear to rotate, the main bevel gearand auxiliary bevel gears are in meshing transmission to drive threaded rods of the sliding grooves to rotate, at the moment, sliding columns of the limiting mechanisms get close to the inner side along with rotation of the threaded rods, movable bases make contact with the surface of the tank body, first movable rods are driven to move to compress first springs, the tank body is limited throughthe movable bases due to reaction generated by the first springs, when the first movable rods move, limiting rods make contact with the surface of the tank body in sequence, and the limiting rods at different positions drive second movable rods to move by different distances; and through elastic deformation of second springs, it is guaranteed that the limiting rods make contact with the surface ofthe tank body for secondary limiting, and tank bodies of different specifications can be clamped and limited.

Owner:马鞍山天哲环保科技有限公司

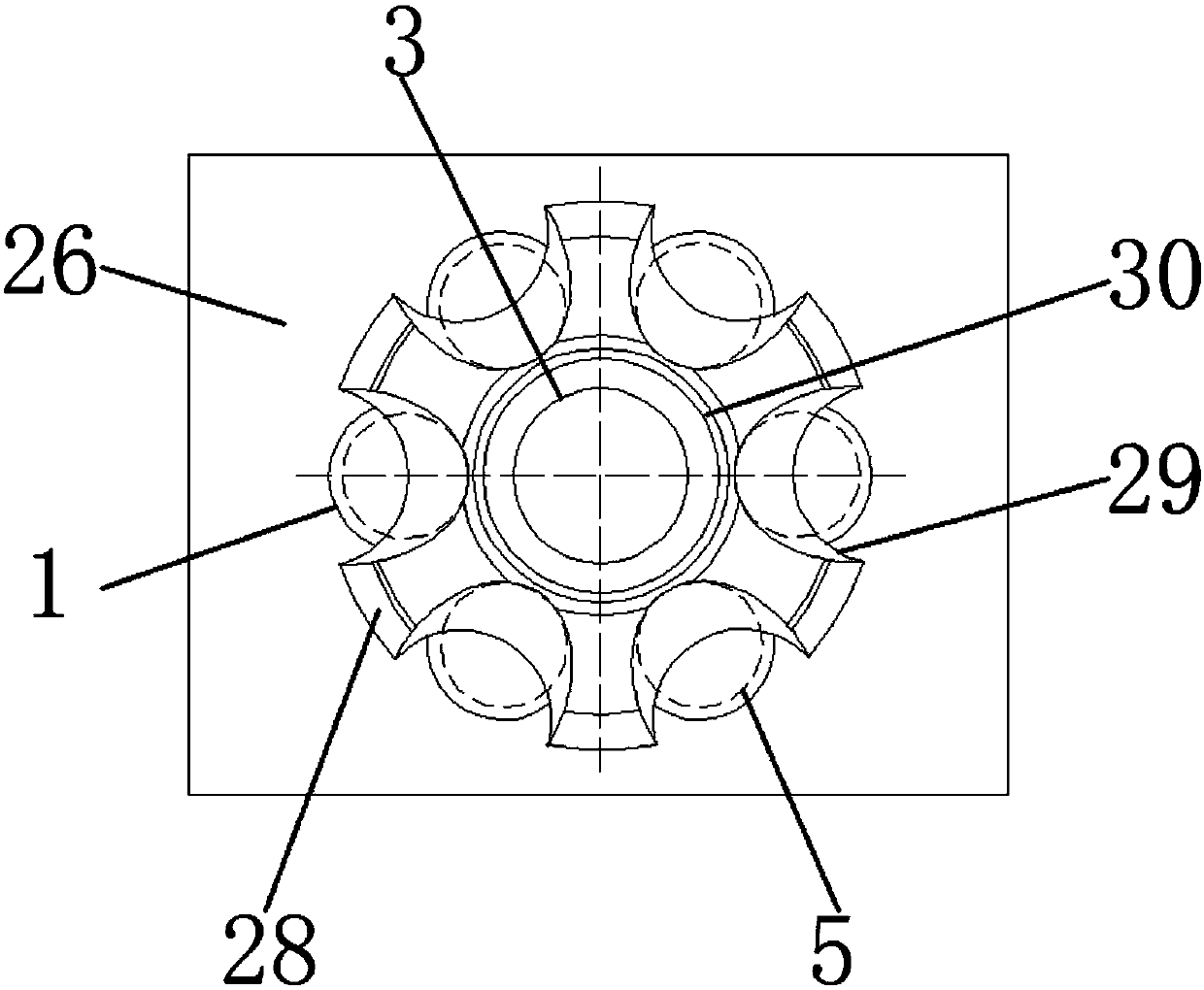

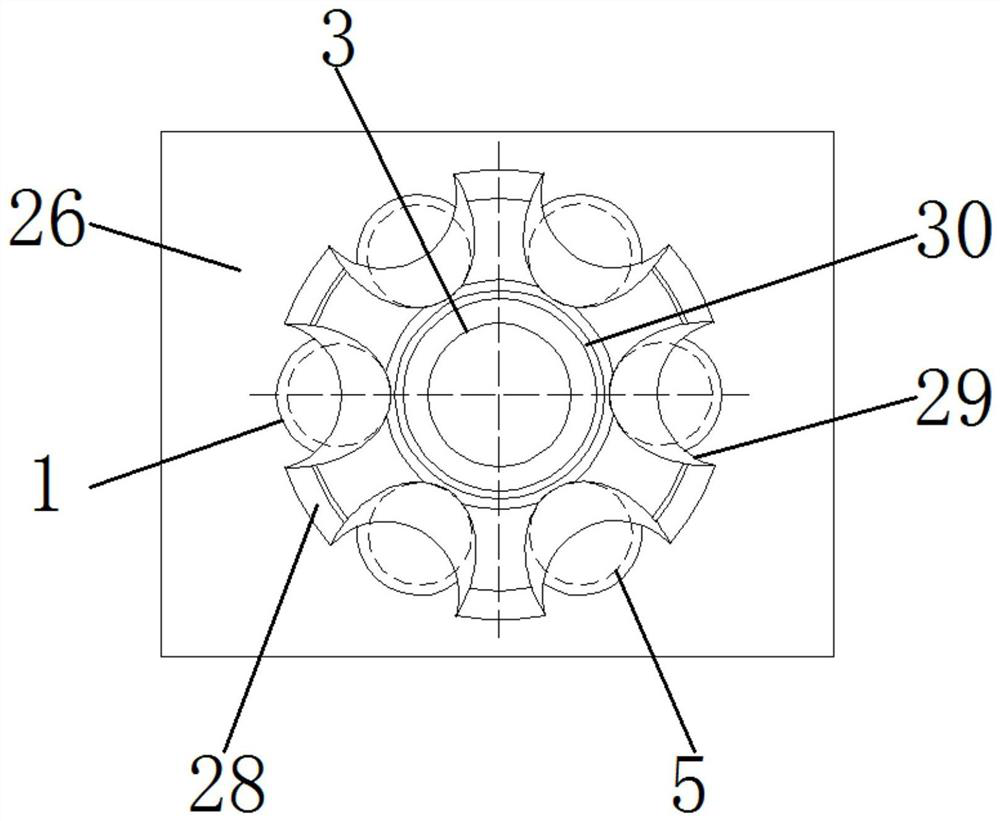

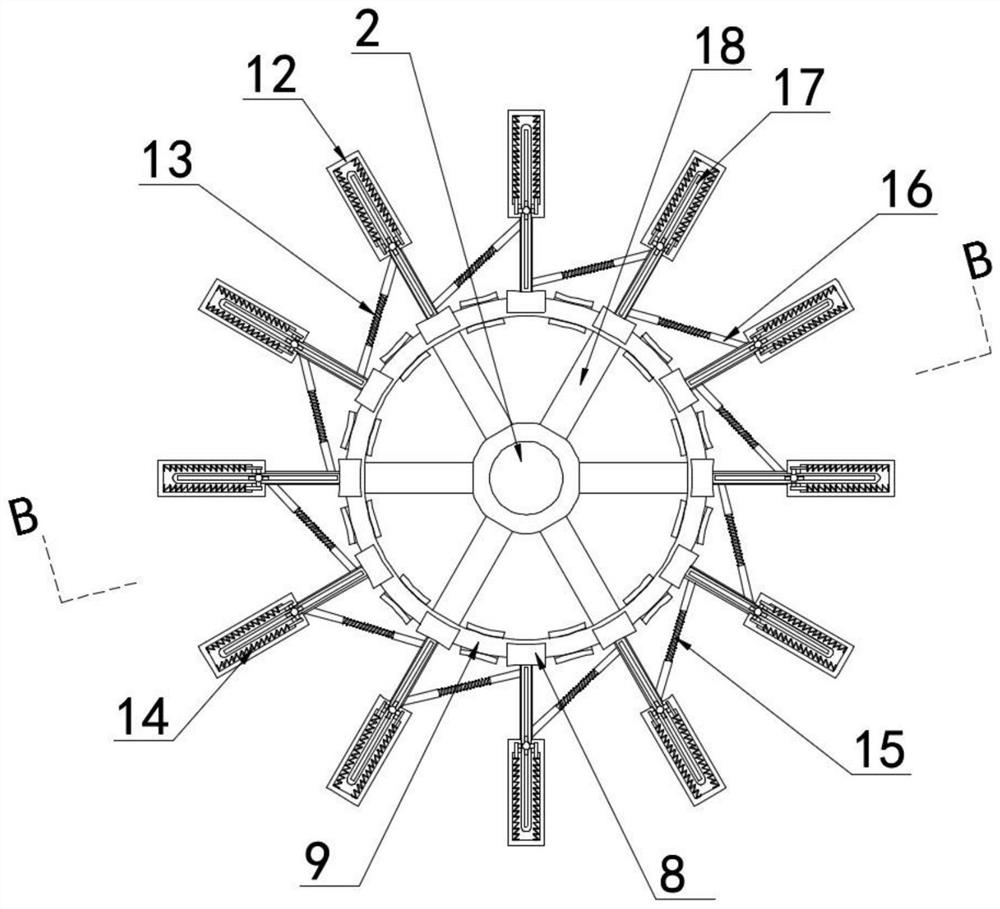

System arrangement device for motor stator punching sheet production

ActiveCN114094777ARealize clamping limitAdjustable sliding directionManufacturing stator/rotor bodiesPunchingElectric machine

The invention discloses a systematic arrangement device for motor stator punching sheet production. The system arrangement device comprises an annular frame and a rotating disc connected with the inner wall of the annular frame in a screwed mode, wherein a base is rotationally connected to the center of the bottom part of an inner cavity of the annular frame through a rotating shaft, a vibration motor is fixedly connected between an opening of the base and the annular frame, a vertical column is fixedly installed at the top end of the base, the outer side of the base is fixedly connected with an annular sleeve through a first connecting rod, a sliding block is slidably connected into the sliding groove, a side column is fixedly installed on the sliding block, and the side column is rotationally connected with a rotating frame through a rotating shaft. According to the systematic arrangement device, due to the adoption of a turnover type bidirectional adjustable push rod structure, motor stator openings with openings in different directions can be clamped and limited, and due to the adoption of a shaft connection adjustable mounting structure, the motor stator openings with various numbers of openings can be matched for use; therefore, the systematic arrangement device is suitable for the motor stator punching sheet with multiple hole slots.

Owner:湖南威斯特机电科技股份有限公司

Radian turning tool of scrap cutter with rapid splicing structure in longitudinal direction

InactiveCN114559063AAchieve pre-positioningAchieve initial positioningPositioning apparatusTurning machinesClassical mechanicsEngineering

The invention relates to the technical field of radian turning tools, in particular to a radian turning tool with a scrap cutter longitudinally provided with a rapid splicing structure, which comprises a connecting seat, a first mounting seat is fixed on the side wall of the connecting seat, a second mounting seat is arranged on the side wall of the first mounting seat, and a workpiece is arranged between the second mounting seat and the first mounting seat; and the splicing mechanism comprises a positioning rod, the positioning rod is fixed to the surface of the second mounting base, a positioning hole corresponding to the positioning rod is formed in the workpiece, an inserting rod is fixed to the side, close to the connecting base, of the positioning rod, and an inserting cavity corresponding to the inserting rod is formed in the first mounting base. According to the clamping device, pre-positioning of a workpiece can be achieved, initial positioning between the workpiece and the second mounting base can be achieved, and when the movable plate moves, limiting clamping of the grabbing clamp on the workpiece can be controlled, rapid fixing of the workpiece can be achieved, and pressing of the rubber clamping plate on the workpiece is achieved, so that cooperation is achieved.

Owner:南京宝佳刀具制造有限公司

Device and method for pulling cover of membrane module

InactiveCN110817772AGuarantee the quality of cap removalAvoid spendingFlanged caps applicationEngineeringAir compressor

The invention discloses a device for pulling a cover of a membrane module. The device comprises a supporting frame and a connecting frame, the bottom of the supporting frame is fixedly connected withthe surface of the connecting frame through supporting legs, an air compressor is fixedly connected with one side of the top of the connecting frame, one side of the top of the supporting frame is fixedly connected with an air cylinder through a fixing frame, an air outlet of the air compressor is in communication with an air outlet pipe, the end, away from the air cylinder, of the air outlet pipeis in communication with an air inlet of the air cylinder, a clamping block is fixedly connected with the output end of the air cylinder, the top and the bottom of the clamping block are in thread connection with screw rods, and one end of each screw rod penetrates through the clamping block and extends into the clamping block. The invention relates to the technical field of membrane separation water treatment equipment. According to the device and method for pulling the cover of the membrane module, compared with a mode of pulling the cover manually, the controllability is high, meanwhile, the production efficiency is improved, the yield can reach 100%, the consumption of manpower resources is avoided, and the cover pulling quality of the membrane assembly is guaranteed.

Owner:XINJIANG DELAND

Metal plate automatic machining and welding device

InactiveCN114393363ARealize clamping limitReduce the phenomenon of deviation from the original positionWelding/cutting auxillary devicesAuxillary welding devicesElectric machinerySlide plate

The invention relates to the technical field of metal plate machining, and discloses an automatic metal plate machining and welding device which comprises a box body, a portal frame is mounted on the upper surface of the box body, a moving plate is arranged in the portal frame, a toothed plate is arranged in the moving plate, and a welding equipment body is arranged on the lower surface of the toothed plate. A sliding seat is slidably arranged in the box body, a clamping frame is installed on the upper surface of the sliding seat, and a transmission plate is installed on the lower surface of the sliding seat. According to the automatic machining and welding device for the metal plate, a second push rod motor pushes a sliding plate to slide downwards along a limiting sliding rail, the sliding plate drives a transmission plate to move towards the inner side through a hinge base and a connecting plate, the transmission plate drives a clamping frame to clamp and position the metal plate through a sliding base, clamping and limiting of the metal plate are achieved, and the machining precision of the metal plate is improved. The probability that the metal plate deviates from the original position is reduced, and the machining effect on the metal plate is guaranteed.

Owner:深圳兴准科技有限公司 +1

Stabilizing device for air pipe inside integrated stove and method of device

PendingCN111503687AEnsure the basic structureEnhanced Structural Balance PerformanceDomestic stoves or rangesLighting and heating apparatusThermodynamicsStructural engineering

The invention discloses a stabilizing device for an air pipe inside an integrated stove. The stabilizing device comprises stabilizing end frames and a stabilizing supporting plate; the stabilizing endframes is adjustably connected with the stabilizing supporting plate; each stabilizing end frame comprises a main supporting rod, an adjusting plate and side supporting plates, limiting rods are arranged on the main supporting rod, the adjusting plate is adjustably fixed to the top surface of the main supporting rod, the limiting rods are movably sleeved with the side supporting plates, the sidesupporting plates are connected with the adjusting plate through connecting rods, and an ejection component is arranged between the two side supporting plates. The mounting method of the stabilizing device includes the following steps that (1) the stabilizing end frames are assembled; (2) the stabilizing end frames and the stabilizing supporting plate are mounted; (3) the air pipe and the stabilizing device are mounted; and (4) the air pipe and the integrated stove are mounted. According to the stabilizing device, the two ends of the air pipe are supported and stabilized by the aid of the stabilizing end frames, the tops of the two ends of the air pipe are pressed and limited by the aid of the ejection components, and then the stabilizing supporting plate assists in supporting the middle of the air pipe, so that the structural stability of the air pipe is guaranteed effectively, and smoke in the air pipe is discharged more smoothly.

Owner:浙江蓝炬星电器有限公司

Fender compression performance detection device

ActiveCN113654789AClose to each otherEnable mobilityMachine part testingSupporting partsFenderControl engineering

The invention discloses a fender compression performance detection device, and relates to the technical field of fender performance detection. The fender compression performance detection device comprises a mobile platform assembly, a fender limiting and clamping unit and a rack are installed at the top of the mobile platform assembly, and a movable fender compression detection assembly is installed on the rack; the fender compression detection assembly is used for detecting the compression performance of the fender; the fender limiting and clamping unit comprises a moving assembly, a rotary clamping assembly and a supporting assembly which are connected, and the moving assembly is used for moving the rotary clamping assembly to clamp and limit the fender. The fender compression performance detection device is reasonable in structure, fenders with different lengths and sizes can be clamped and limited, clamping is firm, the practicability is improved, the fenders clamped between a pair of limiting and clamping shells can rotate, next-step compression performance detection can be conveniently carried out on the peripheries of the fenders, and compression performance detection on different positions in the length direction of the fender is achieved, and the detection range is widened.

Owner:江苏弘业检测技术有限公司

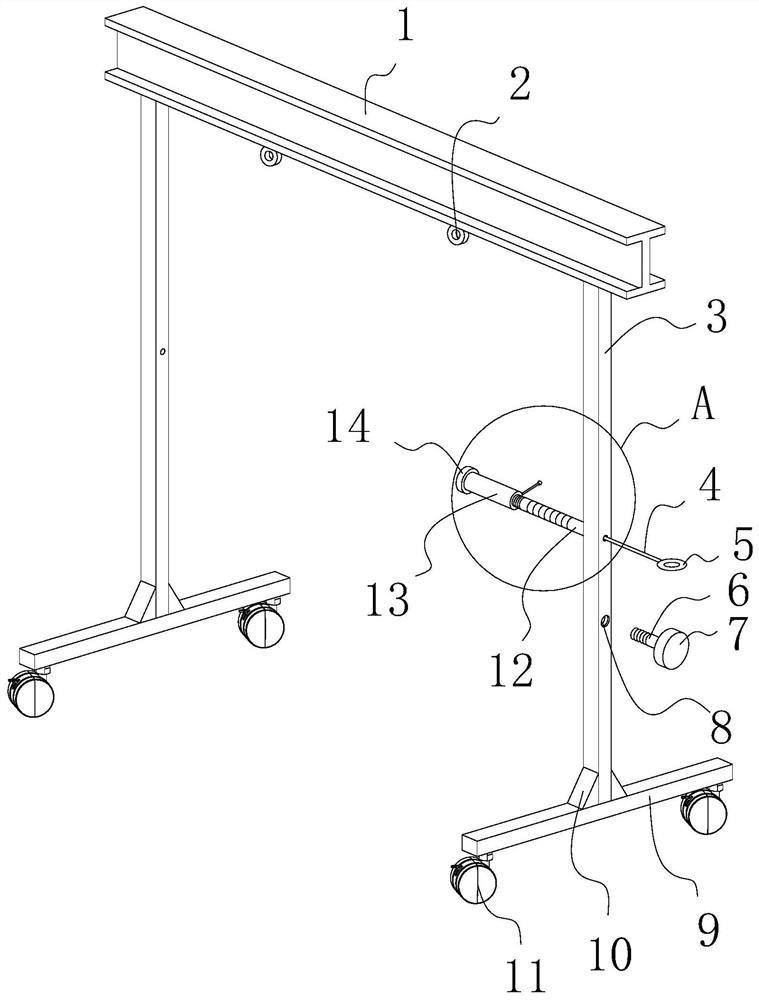

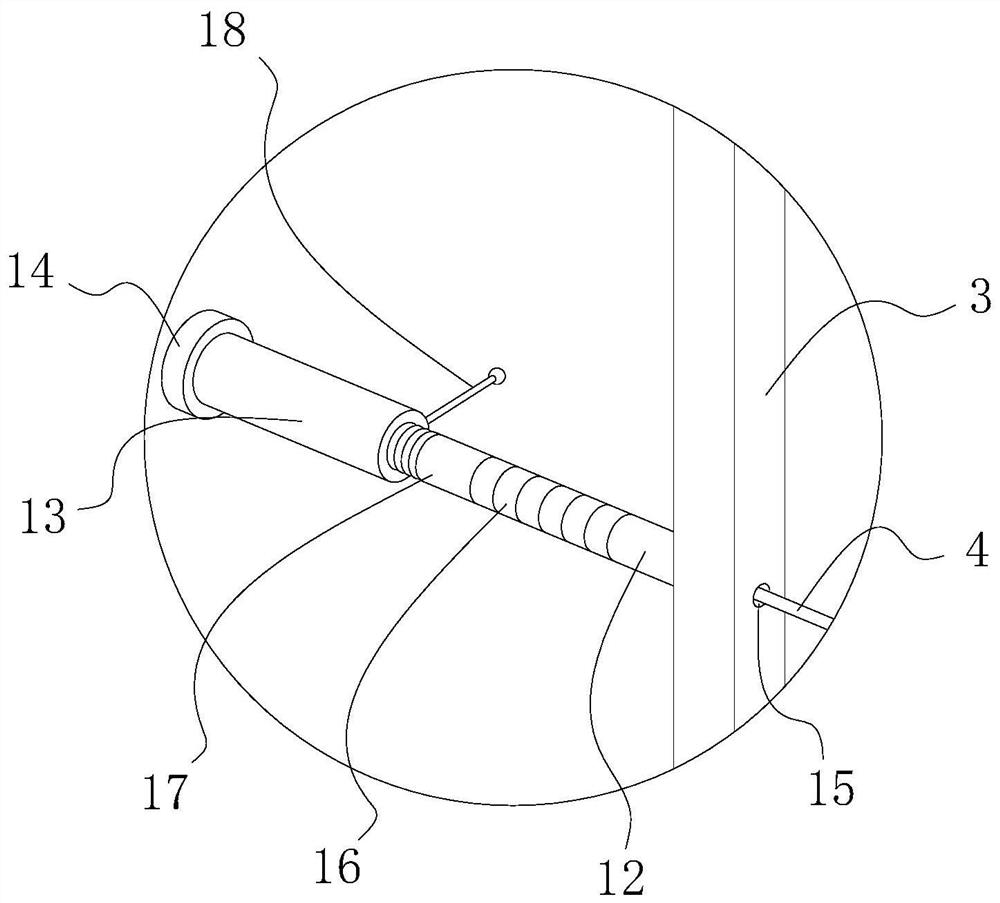

Spacing-adjustable electrical cabinet lifting frame

PendingCN112875503AImplement active connectionSmall footprintBase supporting structuresBraking devices for hoisting equipmentsClassical mechanicsStructural engineering

The invention relates to the technical field of electrical cabinet lifting, in particular to a spacing-adjustable electrical cabinet lifting frame which comprises a cross beam. Two vertically-arranged supporting legs are symmetrically installed on the lower surface of the cross beam, and horizontally-arranged supporting rods are fixed to the middle positions of the opposite faces of the two supporting legs; the ends, away from the supporting legs, of the supporting rods are hinged to a plurality of circular truncated cones connected in series, and the ends, away from a first rectangular frame, of the circular truncated cones are hinged to half-tooth studs; traction ropes are tied to the faces, provided with the second rectangular frame, of the half-tooth studs; the other ends of the traction ropes sequentially penetrate through a second through hole, a first through hole and a penetrating hole and are connected with pull rings, and threaded blind holes are formed in the lower portions of the faces, away from the supporting rods, of the supporting legs; and a limiting rod used for limiting the position of the pull rings is in threaded connection with the interior of the threaded blind hole, and an inner threaded cylinder is in threaded connection with the half-tooth studs. Compared with the prior art, the spacing-adjustable electrical cabinet lifting frame has the following beneficial effect that an electric cabinet hung on the cross beam is prevented from shaking.

Owner:蒋阳

Adjustable medicine detection cabinet convenient for arranging liquid medicine containers

PendingCN111514946AAvoid displacementConvenient ArrangementSupporting apparatusHazardous material storageEngineeringMechanical engineering

The invention discloses an adjustable medicine detection cabinet facilitating arrangement of liquid medicine containers. The medicine detection cabinet comprises a medicine detection cabinet body, a detection window, an operation interface and a drain pipe, a detection window is formed in the front side of the medicine detection cabinet body; an operation interface is arranged on one side of the detection window; a placement opening is formed in the lower part of the medicine detection cabinet body; and meanwhile, the placement opening is connected with a placing frame through a guide rail, aplacing bin is arranged on the rear side of the placing opening, a supporting plate is arranged at the bottom of the placing bin, a water filtering hole is formed in the supporting plate, a flow guiding groove is formed below the supporting plate, and a liquid discharging pipe is arranged on the rear side of the medicine detection cabinet body. According to the adjustable medicine detection cabinet, the liquid medicine containers can be arranged and placed in a distinguished mode, the liquid medicine containers can be clamped and limited, and the problem that the liquid medicine containers shake or are broken when the medicine detection cabinet body is moved is avoided.

Owner:青海省药品检验检测院

Automatic material clamping device

PendingCN113955478AGuaranteed multi-angle adjustment flexibilityHigh degree of automationConveyorsPackagingRobot handEngineering

The invention provides an automatic material clamping device comprising an installation arm used for being detachably connected with a mechanical arm. Supporting arms capable of sliding in the length direction of the installation arm are arranged at the two ends of the installation arm correspondingly, and a first driving assembly used for driving the two supporting arms to be close to each other or separated from each other is arranged on the installation arm. Clamping mechanisms are arranged on the two supporting arms correspondingly. Wedge-shaped guide parts are arranged on the two clamping mechanisms correspondingly so that the two clamping mechanisms can clamp plate-shaped materials which are horizontally placed on a horizontal tabletop. According to the automatic material clamping device, automatic and stable clamping of horizontally-placed plates can be achieved, and the working efficiency is effectively improved.

Owner:NINGBO TUOPU GROUP CO LTD

A processing equipment for shaping and processing leather wire and optical cable

ActiveCN111017642BPrevent twistingPrevention of twistingFilament handlingFibre mechanical structuresEngineeringCable transport

The invention discloses a sizing and processing equipment for a sheathed optical cable, which belongs to the technical field of optical fiber production, and comprises a fixed plate, a vertical plate, an optical cable conveying component, a bearing frame, an optical cable limiting component and an optical cable winding component. One end of the top of the fixed plate, the optical cable transport assembly is installed on the vertical plate, the carrier is arranged on the fixed plate, and the carrier is located on the side of the vertical plate, and the optical cable is limited. The positioning assembly is installed on the carrier frame, the optical cable winding assembly is installed on the fixing plate, and the optical cable winding assembly is located on the side of the carrier frame. The invention solves the problem that when the existing sheathed optical cable is reeled after production, there is torsional stress when the sheathed optical cable is paid out. This leads to the phenomenon of twisting and breaking of the leather cable, which affects the quality of the leather cable.

Owner:叶友岳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com