Tower crane boom welding device

A technology for welding devices and booms, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of failure to meet installation requirements, high difficulty, and high operation requirements, and achieve fast clamping and dismounting, The effect of simplifying the production process and preventing bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

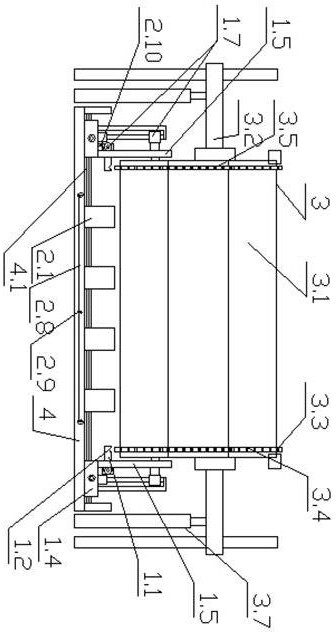

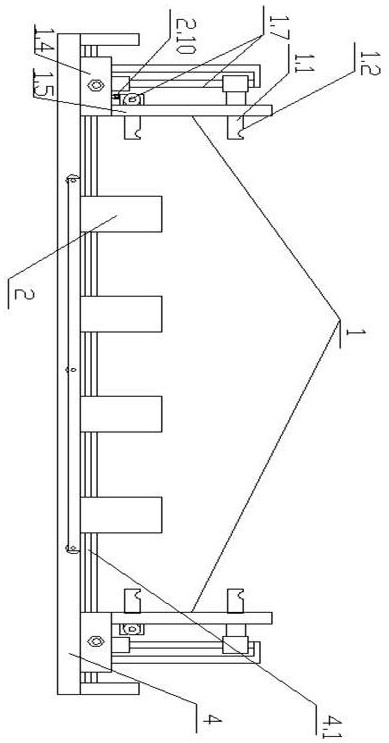

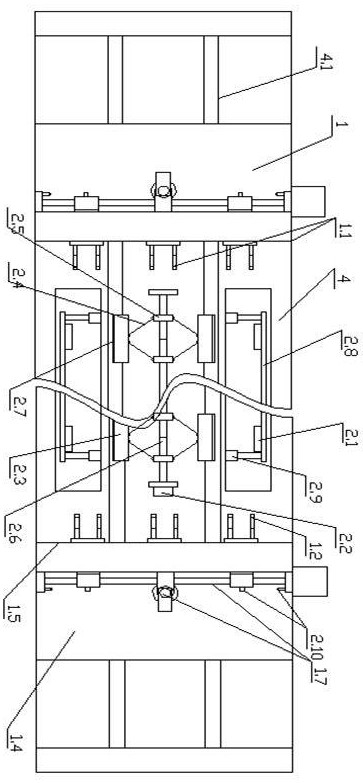

[0016] Now in conjunction with accompanying drawing, the present invention is further elaborated.

[0017] like Figure 1-6 As shown, a welding device for the boom of a tower crane includes a clamping mechanism 1, a clamping mechanism 2 and an automatic conveying mechanism 3. It is fixed on the ground by means of bolt fastening and is equipped with an installation base 4. On the installation base 4 is provided with a sliding assembly 4.1 (the sliding assembly 4.1 is the sliding track, the sliding seat and the locking bolt, the sliding track is fixed on the installation base 4 by welding, and the sliding track is nested on the sliding seat to move The moving seat is provided with a locking bolt passing through and against the sliding track on the moving seat, and the sliding seat is locked by the locking bolt, so that the adjustment and locking of the sliding seat can be realized), and the sliding assembly Both ends of 4.1 are provided with a clamping mechanism 1 that moves on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com