Water tank full water inlet control system with probe

A water inlet control and water tank technology, applied in special distribution devices, containers, packaging, etc., can solve problems such as wasting space, affecting user experience, and water outlet delay, so as to achieve the effect of optimizing application and avoiding water outlet delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

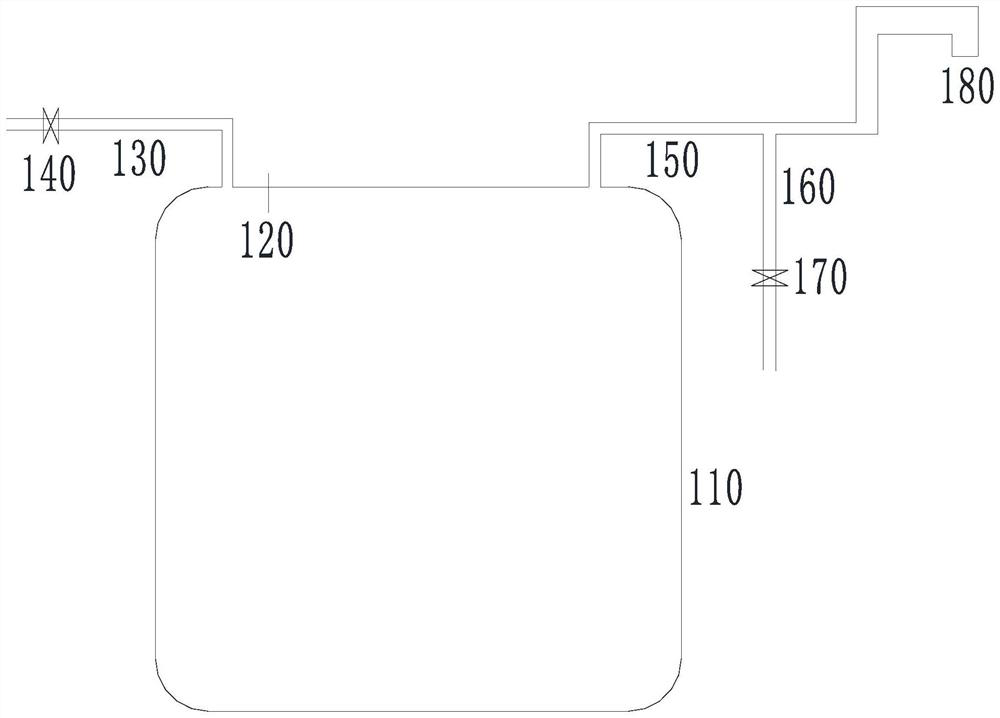

[0020] Exemplary embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. Although exemplary embodiments of the present invention are shown in the drawings, it should be understood that the invention may be embodied in various forms and should not be limited to the embodiments set forth herein. Rather, these embodiments are provided for more thorough understanding of the present invention, and to fully convey the scope of the present invention to those skilled in the art.

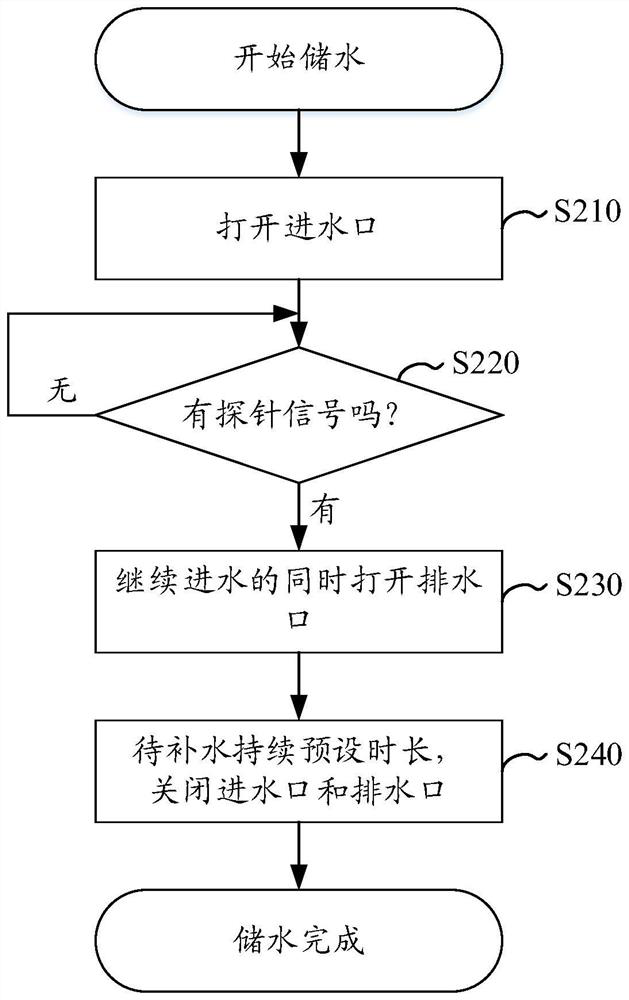

[0021] A liquid level probe is installed on the top of the water tank. During the water storage process of the water tank, when the water level gradually rises and contacts the liquid level probe, the detection of the liquid level can be realized by using the liquid level probe to contact the water to conduct electricity. But in fact, the water tank was not full when the signal of the liquid level probe was just detected, and there was still a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com