SBS/rubber powder composite modified asphalt based on Xinjiang asphalt and preparation method thereof

A technology of composite modified asphalt and asphalt, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of poor storage stability and insufficient high and low temperature performance, and achieve stable thermal storage, better softening point, and high softening point Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a kind of SBS / rubber powder composite modified asphalt based on Xinjiang asphalt, which is characterized in that, in parts by weight, it is made of the following raw materials: Xinjiang blended asphalt is 100 powder, SBS is 2 parts, rubber powder 10 parts, compatibilizer 1.5 parts, plasticizer 2 parts, reinforcing agent 1 part, coupling agent 0.5 parts, stabilizer 0.2 parts.

[0043] Specifically, the reinforcing agent is tetraacicular zinc oxide whisker (T-ZnOw).

[0044] Specifically, Xinjiang blended asphalt is prepared by blending Karamay 90# asphalt and Tahe 60# asphalt in a weight ratio of 60:40. .

[0045] The preparation method of the SBS / rubber powder composite modified asphalt based on Xinjiang asphalt of this embodiment specifically includes the following steps:

[0046] Step 1, SBS preprocessing:

[0047] Weigh the SBS and the compatibilizer, preheat the SBS and the compatibilizer to 50°C respectively, after the compatibilizer has...

Embodiment 2

[0059] This embodiment provides a kind of SBS / rubber powder composite modified asphalt based on Xinjiang asphalt, which is characterized in that, in parts by weight, it is made of the following raw materials: Xinjiang blended asphalt is 100 powder, SBS is 3 parts, rubber powder 10 parts, compatibilizer 2.5 parts, plasticizer 3 parts, reinforcing agent 2 parts, coupling agent 1 part, stabilizer 0.2 parts.

[0060] Specifically, the reinforcing agent is tetraacicular zinc oxide whisker (T-ZnOw).

[0061] Specifically, Xinjiang blended asphalt is prepared by blending Karamay 90# asphalt and Tahe 60# asphalt in a weight ratio of 45:55. .

[0062] The preparation method of the Xinjiang asphalt-based SBS / rubber powder composite modified asphalt in this example is the same as that in Example 1.

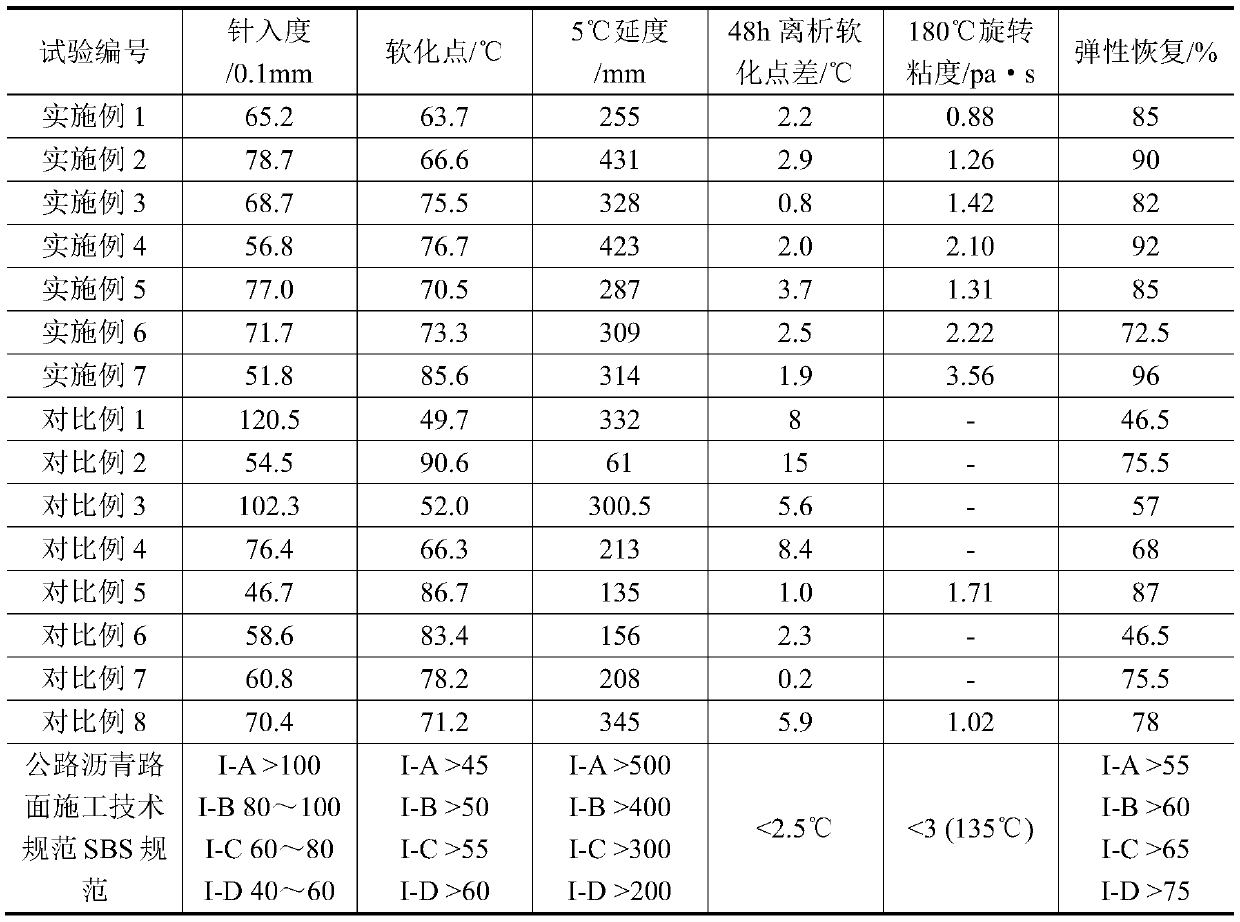

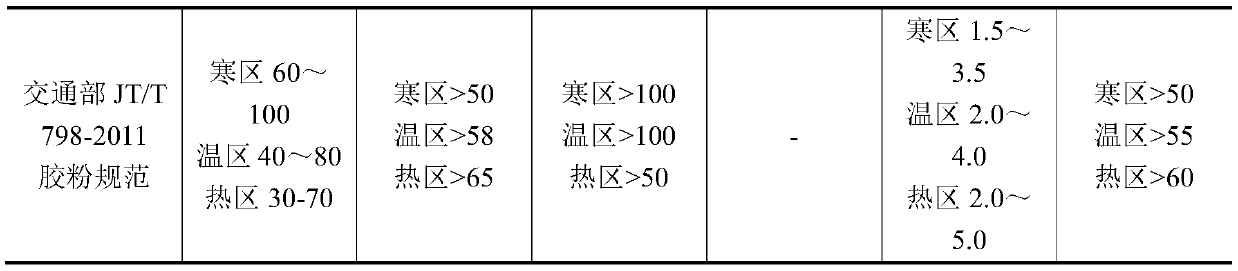

[0063] The performance test results of this embodiment are shown in Table 1.

Embodiment 3

[0065] This embodiment provides a kind of SBS / rubber powder composite modified asphalt based on Xinjiang asphalt, which is characterized in that, in parts by weight, it is made of the following raw materials: Xinjiang blended asphalt is 100 powder, SBS is 3 parts, rubber powder 15 parts, compatibilizer 1.5 parts, plasticizer 4 parts, reinforcing agent 2 parts, coupling agent 1 part, stabilizer 0.2 parts.

[0066] Specifically, the reinforcing agent is tetraacicular zinc oxide whisker (T-ZnOw).

[0067] Specifically, Xinjiang blended asphalt is prepared by blending Karamay 90# asphalt and Tahe 60# asphalt in a weight ratio of 45:55. .

[0068] The preparation method of the Xinjiang asphalt-based SBS / rubber powder composite modified asphalt in this example is the same as that in Example 1.

[0069] The performance test results of this embodiment are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com