Preparation method for integral material of hierarchical porous structure

A monolithic material and multi-level pore technology, which is applied in the field of preparation of multi-level pore monolithic materials, can solve the problems of non-remodeling of materials and restrictions on the practical application of materials, and achieve the effect of promoting application and facilitating the size of multi-level pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

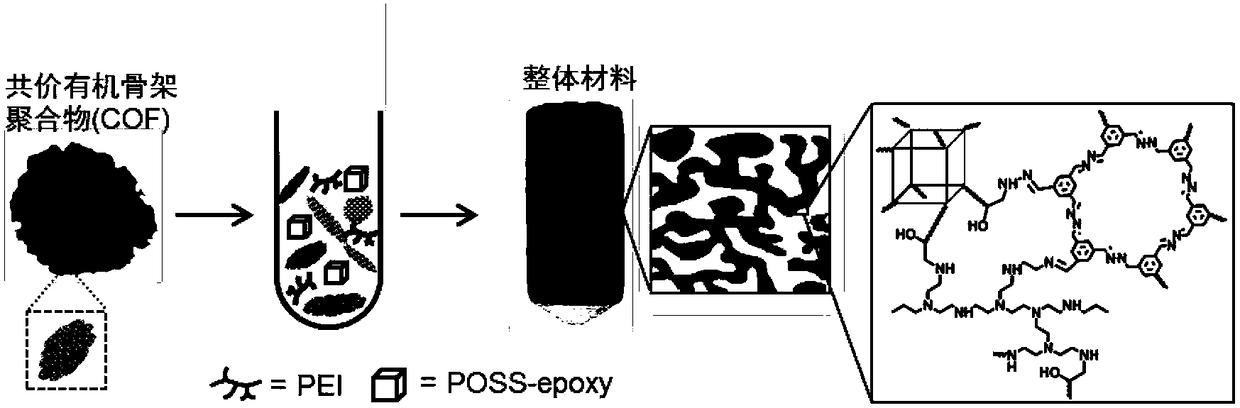

[0023] 1. Add 50.0 mg of POSS-epoxy reagent to the centrifuge tube.

[0024] 2. Add 54.0 mg of PEI aqueous solution to the above centrifuge tube.

[0025] 3. Add 25 mg PEG, 280 μL n-propanol and 40 μL 1,4-butanediol to the above centrifuge tube.

[0026] 4. Add 20 mg of azine-linked COF to the above centrifuge tube, shake the above centrifuge tube for 5 minutes to mix all the components in it evenly.

[0027] 5. React the centrifuge tube in step 4 in a 50°C water bath for 10 hours, and the mixture in the centrifuge tube will form a yellow solid.

[0028] 6. Repeatedly immersing and washing the material in the centrifuge tube with methanol to obtain the azine-linked COF doped hierarchical porous monolithic material.

Embodiment 2

[0030] 1. Add 50.0 mg of POSS-epoxy reagent to the centrifuge tube.

[0031] 2. Add 54.0 mg of PEI aqueous solution to the above centrifuge tube.

[0032] 3. Add 25 mg PEG, 280 μL n-propanol and 40 μL 1,4-butanediol to the above centrifuge tube.

[0033] 4. Add 40 mg of azine-linked COF pre-saturated with toluene to the above centrifuge tube, shake the above centrifuge tube for 5 minutes to mix the components in it evenly.

[0034] 5. React the centrifuge tube in step 4 in a 50°C water bath for 10 hours, and the mixture in the centrifuge tube will form a yellow solid.

[0035] 6. Repeatedly immersing and washing the material in the centrifuge tube with methanol to obtain the azine-linked COF doped hierarchical porous monolithic material.

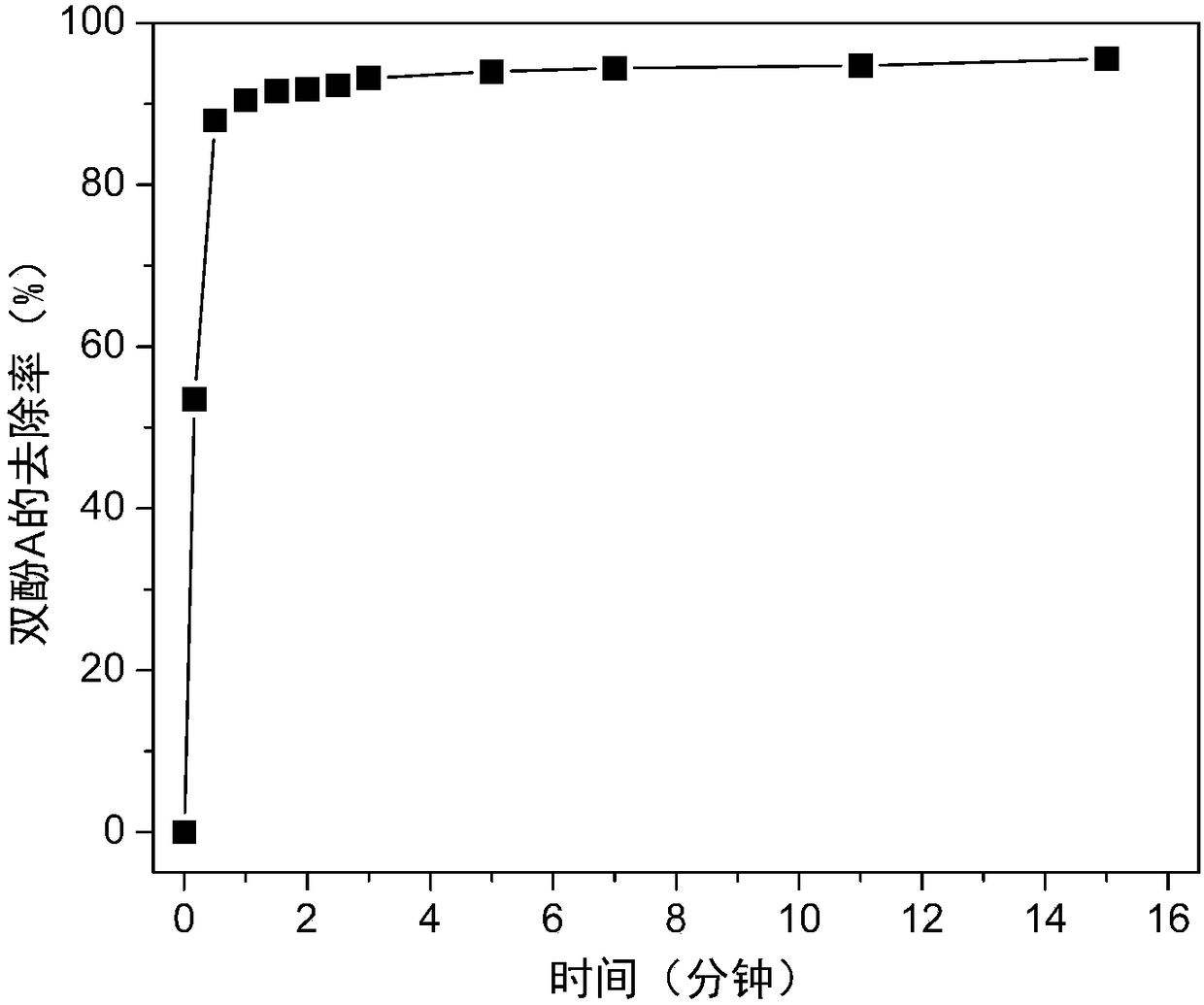

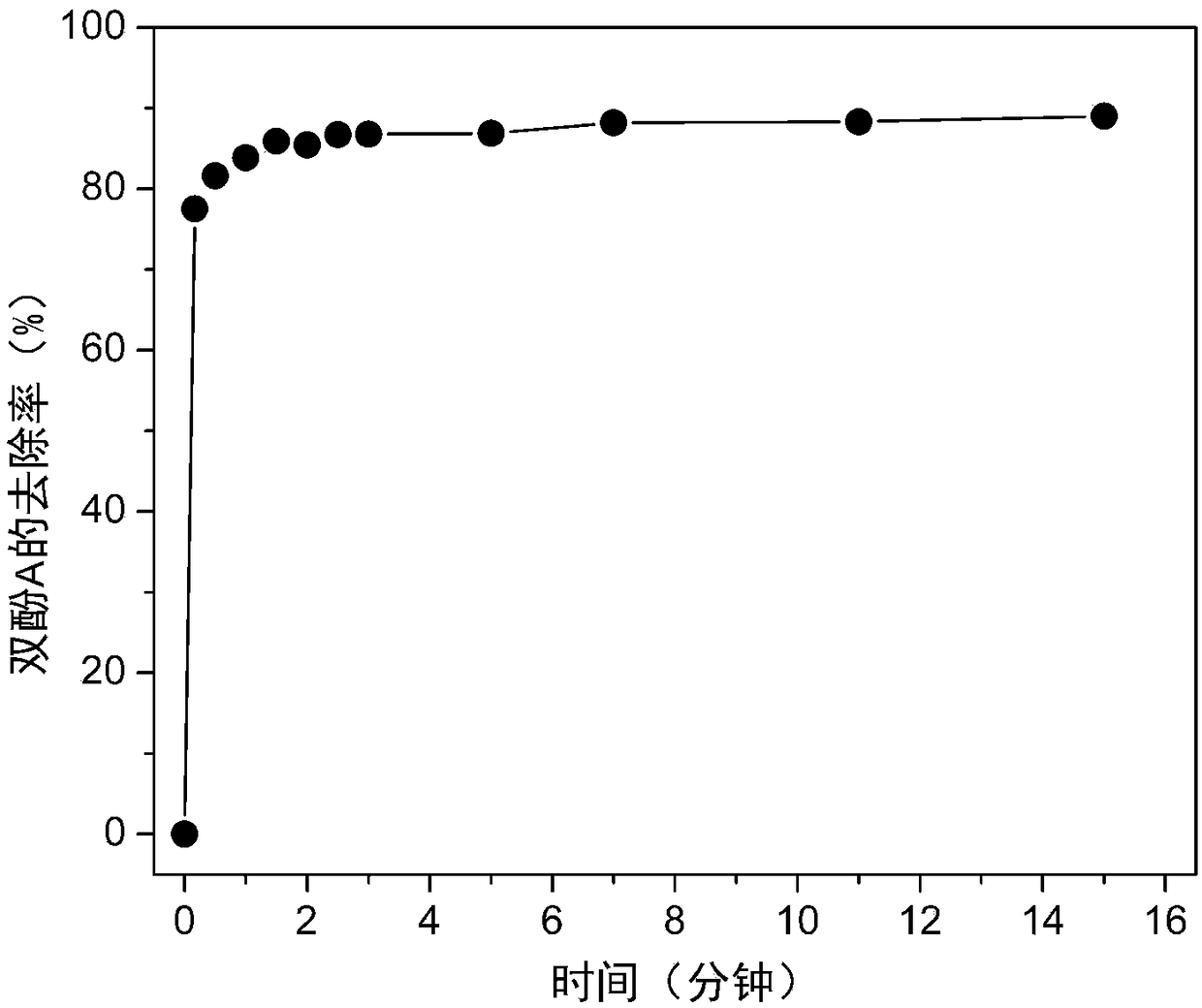

[0036] figure 2 It is the adsorption kinetic curve of the azine-linked COF doped hierarchical porous monolith (Example 1) to bisphenol A in aqueous solution. Experimental conditions: bisphenol A aqueous solution (22.8mg / L); UV-vis detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com