Ship integrated variable-air-volume terminal device

A variable air volume terminal and measurement device technology, which is applied in the directions of hull ventilation/heating/cooling, ship components, ship construction, etc., can solve the problems of difficult realization of ship cabins, difficult application of variable air volume air conditioning technology, etc., and achieve installation space improvement, Promote the performance of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

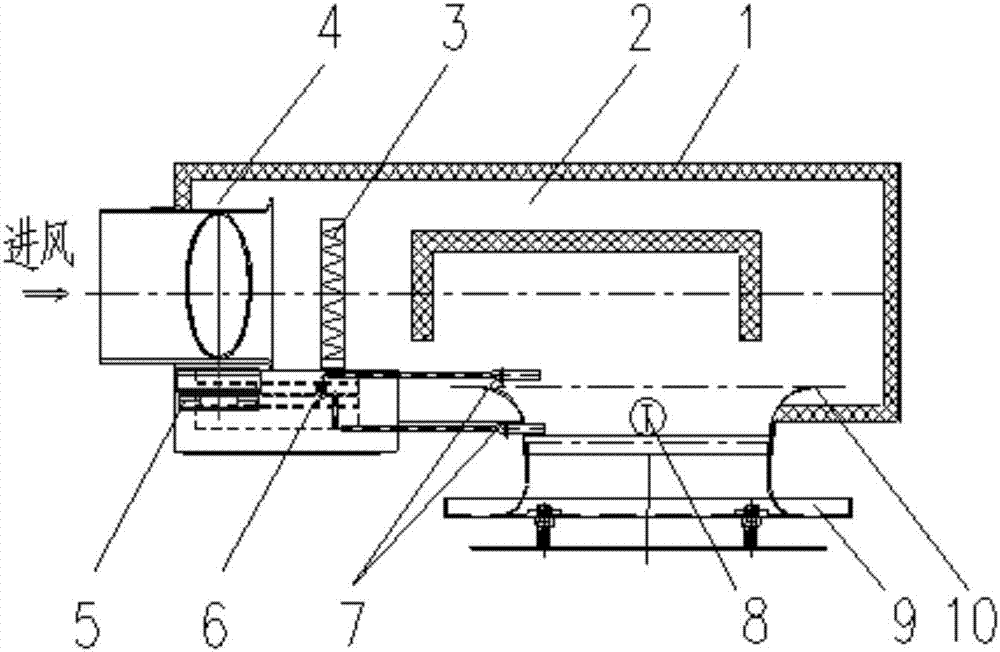

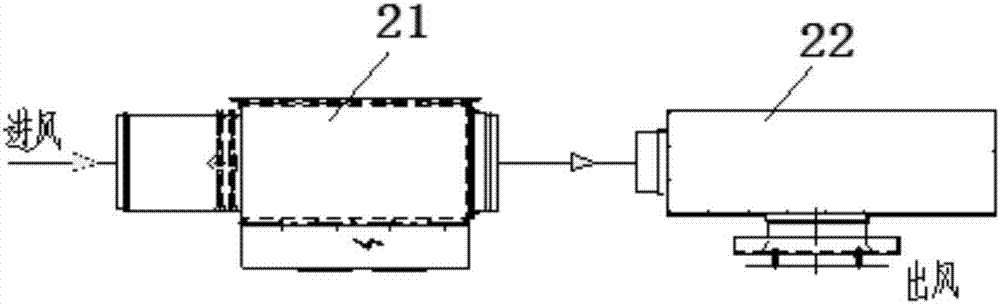

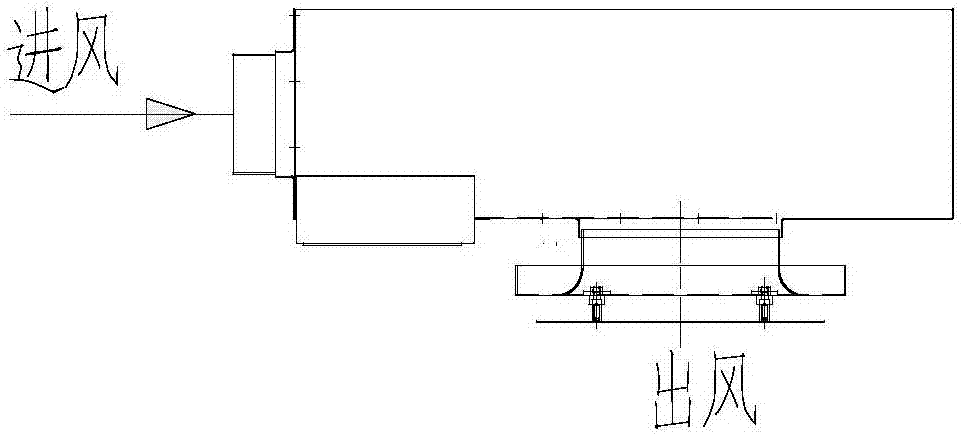

[0017] Such as Figure 2 to Figure 4 As shown, the present invention provides an integrated variable air volume terminal device for a ship, including an anechoic box 1, an anechoic chamber 2, a reheater 3, a damper 4, a damper actuator 5, a terminal controller 6, and air volume measurement The device 7, the temperature measuring device 8, the diffuser 9, the air supply collector 10, and the cabin temperature controller are connected with the terminal controller through signal lines.

[0018] The front end of the muffler box 1 is provided with a regulating air valve 4, and the regulating air valve 4 is connected to the terminal controller 6 through the damper actuator 5, and the terminal controller 6 controls and adjusts the air volume according to the cabin temperature collected by the cabin temperature setting device. A reheater 3 is installed at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com