Graphene-doped resin concrete, preparation method thereof and pulse electromagnetic wave rapid curing method

A technology of resin concrete and graphene, which is applied in the field of steel bridge deck pavement, can solve problems such as difficult control of curing temperature, complex system components, and difficult operation, so as to reduce the activation energy of curing reaction, increase thermal conductivity, and reduce activation energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

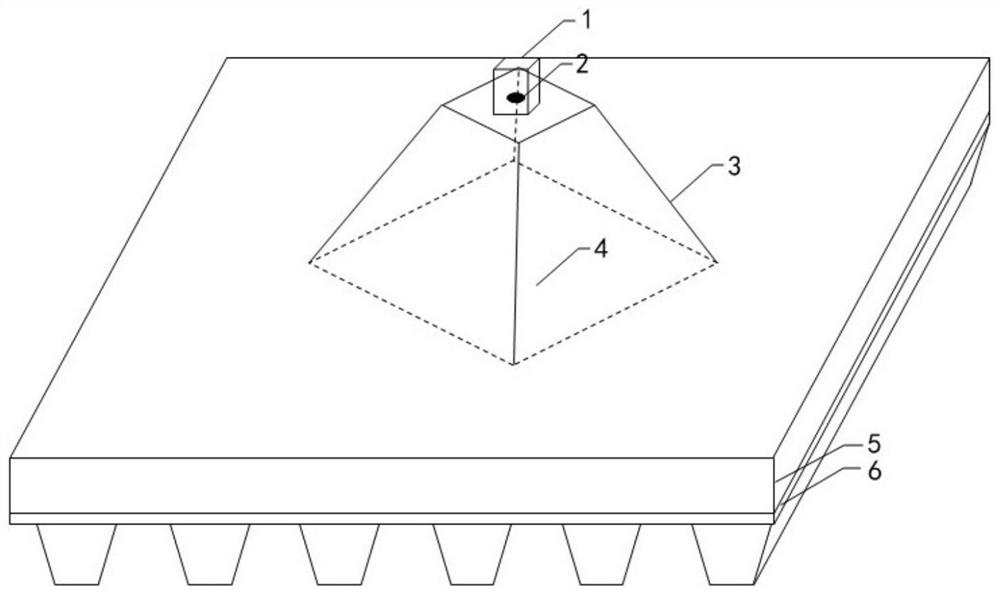

Image

Examples

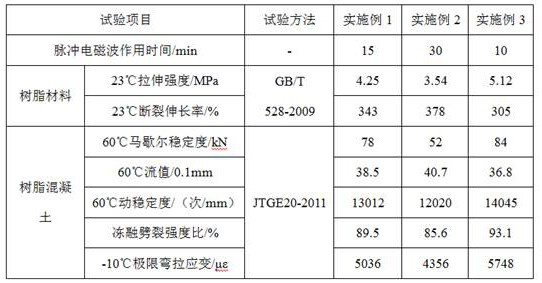

Embodiment 1

[0044] Embodiment 1: a kind of graphene-doped resin concrete comprises following components: 50 parts of bisphenol A type epoxy resin 850, 20 parts of epoxy-terminated urethane prepolymer EPU-73B, Polyethylene Glycol 5 parts of diglycidyl ether, 1 part of KH550 coupling agent, 80 parts of amine curing agent 650, 10 parts of amino-terminated polyether D-2000, EA-05 suspended dense aggregate and graphene powder.

[0045] A kind of preparation method of graphene-doped resin concrete:

[0046] S1. Add 50 parts of bisphenol A epoxy resin 850, 10 parts of epoxy-terminated carbamate prepolymer EPU-73B, 5 parts of polyethylene glycol diglycidyl ether and 1 part of KH550 coupling agent in sequence In a mixer, stir and mix at 50°C for 2 hours to obtain the main ingredient A;

[0047] S2. Put 80 parts of amine curing agent 650 and 10 parts of amino-terminated polyether D-2000 into the mixer in turn, stir and mix for 0.5 hours to obtain curing agent B;

[0048] S3. Put the main agent A ...

Embodiment 2

[0054] Embodiment 2: a kind of graphene-doped resin concrete, comprises following component: bisphenol A type epoxy resin EP440060 parts, epoxy-terminated carbamate prepolymer EPU-133 20 parts, polypropylene glycol diglycidol 10 parts of ether, 2 parts of KH560 coupling agent, 85 parts of amine curing agent m-phenylenediamine, 15 parts of amino-terminated polyether D-400, EA-05 suspended dense aggregate and graphene powder.

[0055] A kind of preparation method of graphene-doped resin concrete:

[0056] S1. Put 60 parts of bisphenol A epoxy resin EP4400, 20 parts of epoxy-terminated carbamate prepolymer EPU-133, 10 parts of polypropylene glycol diglycidyl ether and 2 parts of KH560 coupling agent into the mixer in sequence , stirred and mixed at 50°C for 2 hours to obtain the main ingredient A;

[0057] S2. Put 85 parts of amine curing agent m-phenylenediamine and 15 parts of amino-terminated polyether D-400 into the mixer in turn, stir and mix for 0.5 hours to obtain curing ...

Embodiment 3

[0064] Embodiment 3: a kind of graphene-doped resin concrete, comprises following component: 80 parts of bisphenol F type epoxy resin YD638, 30 parts of epoxy-terminated carbamate prepolymer BH-133, neopentyl glycol 15 parts of diglycidyl ether, 2 parts of KH792 coupling agent, 90 parts of amine curing agent ZC-7115H, 20 parts of amino-terminated polyether D-230, EA-05 suspended dense aggregate and graphene powder.

[0065] A kind of preparation method of graphene-doped resin concrete:

[0066] S1. Add 80 parts of bisphenol F-type epoxy resin YD638, 30 parts of epoxy-terminated carbamate prepolymer BH-133, 15 parts of neopentyl glycol diglycidyl ether and 3 parts of KH792 coupling agent in sequence In a mixer, stir and mix at 50°C for 2 hours to obtain the main ingredient A;

[0067] S2. Put 90 parts of amine curing agent ZC-7115H and 20 parts of amino-terminated polyether D-230 into the mixer in turn, stir and mix for 0.5 hours to obtain curing agent B;

[0068] S3. Put the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap