Sand box device for cast-in-place beam construction and cast-in-place beam construction method

A technology of cast-in-place beams and sand boxes, which is applied to bridges, bridge parts, bridge materials, etc., can solve the problems of difficult control of the falling speed of the bracket, difficulty in accurately controlling the elevation, and difficult control of the sand discharge rate, so as to achieve easy control of the falling speed of the bracket , the operation difficulty is reduced, and the sand discharge rate is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

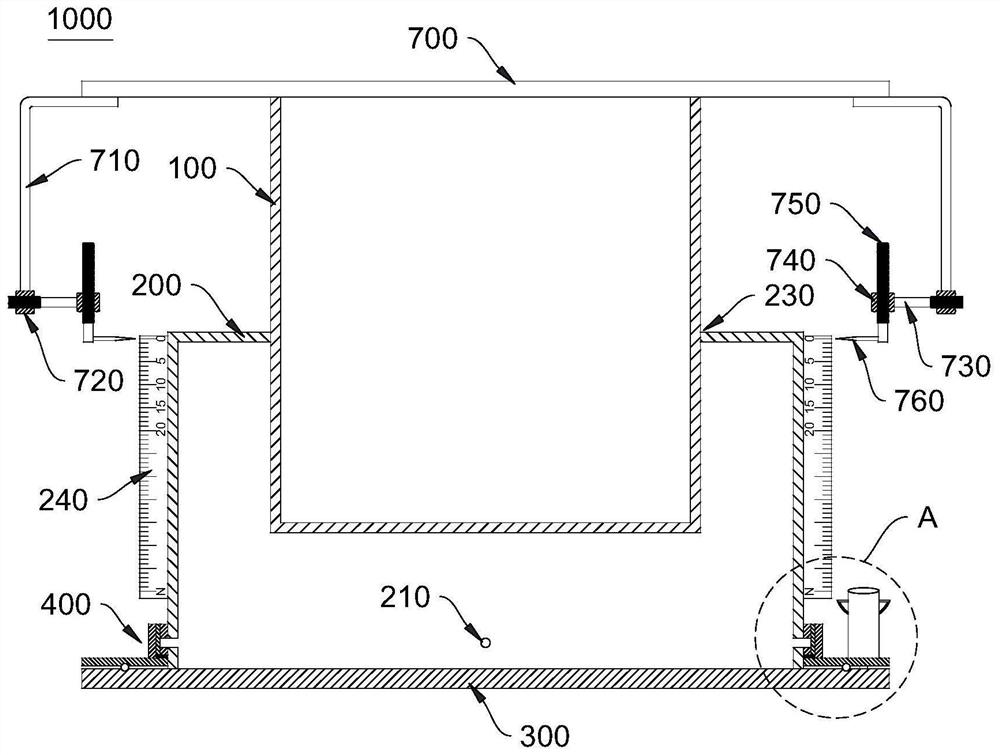

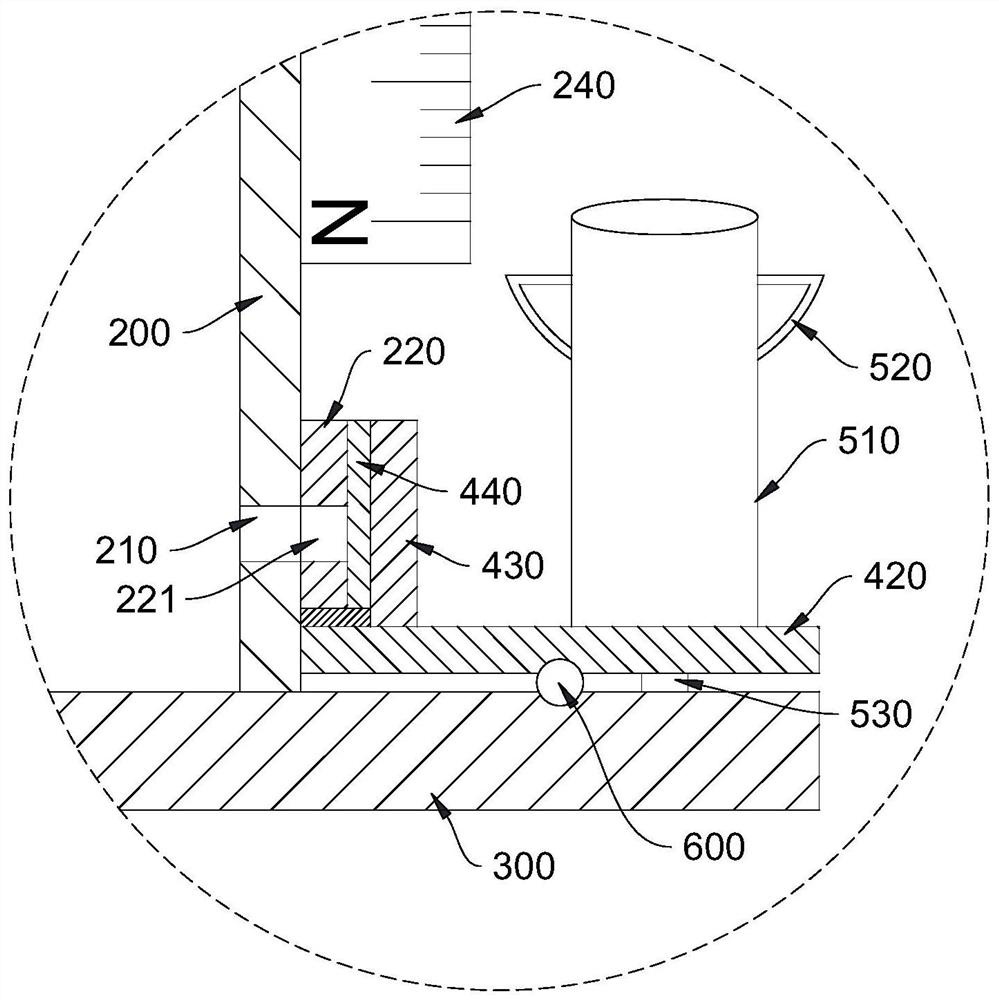

[0046] Please refer to figure 1 , this embodiment provides a sand box device 1000 for the construction of cast-in-place beams. The flask device 1000 includes: an inner cylinder 100 , an outer cylinder 200 , a bottom plate 300 and a rotating member 400 .

[0047] The outer cylinder 200 is installed on the bottom plate 300, and the inner cavity of the outer cylinder 200 is used for filling fine sand.

[0048] The inner cylinder 100 is engaged with the fitting opening 230 , and along the axial direction of the fitting opening 230 , the inner cylinder 100 is slidably mated with the outer cylinder 200 .

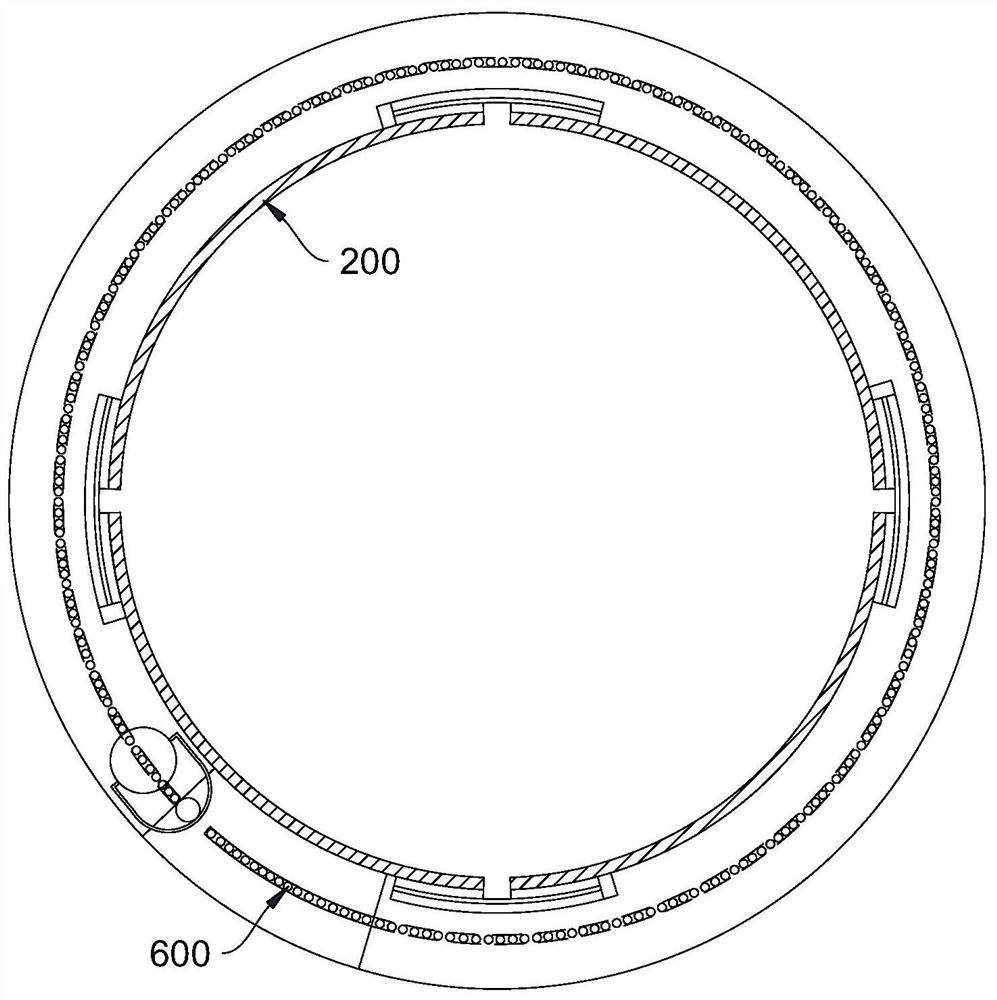

[0049] The rotating part 400 is ring-shaped, and the rotating part 400 is rotatably sleeved on the outer wall of the outer cylinder 200. The rotating part 400 is provided with a gap 410 for fine sand to pass through.

[0050] The rotating member 400 has a first rotational dead point and a second rotational dead point. When the rotating member 400 is at the first dead center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com