Hose winding support

A technology for hose coils and winding racks, which is applied in the direction of pipe brackets, pipes/pipe joints/fittings, special distribution devices, etc., and can solve the problem of damaged hose coiling racks, railings or walls that cannot be hung from railings, etc. Can not get the convenience of use and other issues, to achieve the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

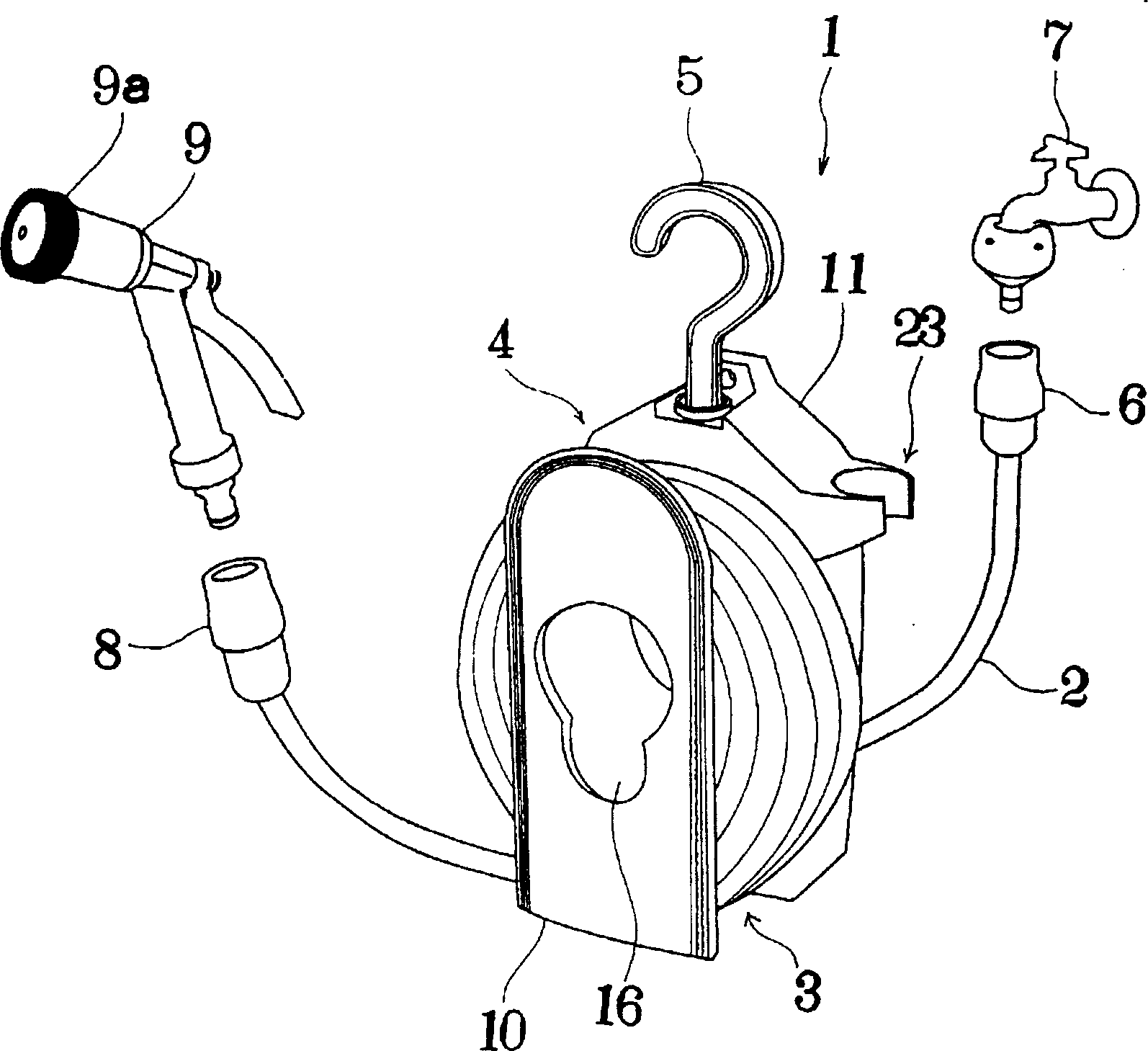

[0020] figure 1 The usage state of the hose reel 1 of the present invention is shown. The hose winding frame 1 is composed of a winding frame body 4 and a hook 5. The winding frame body 4 has a hose winding portion 3 for winding the hose 2; the hook 5 is installed on the winding frame body 4 the upper part. In the figure, 6 is a joint for a water tap, 7 is a water tap, 8 is a joint for a spray gun, and 9 is a sprinkling spray gun.

[0021] The hose reel 1 is designed to store the used hose 2 by winding the hose 2 around the hose reel 3 .

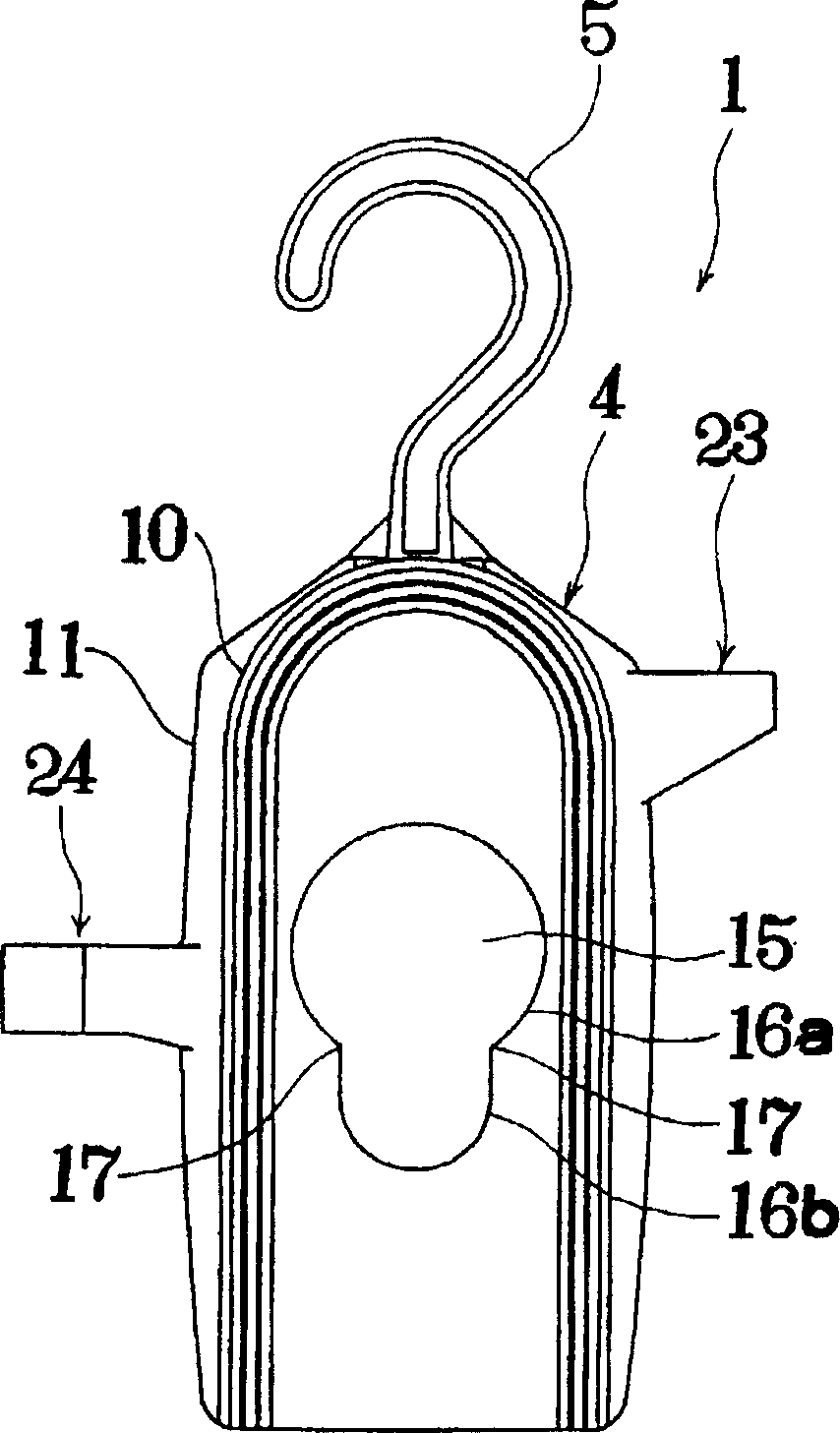

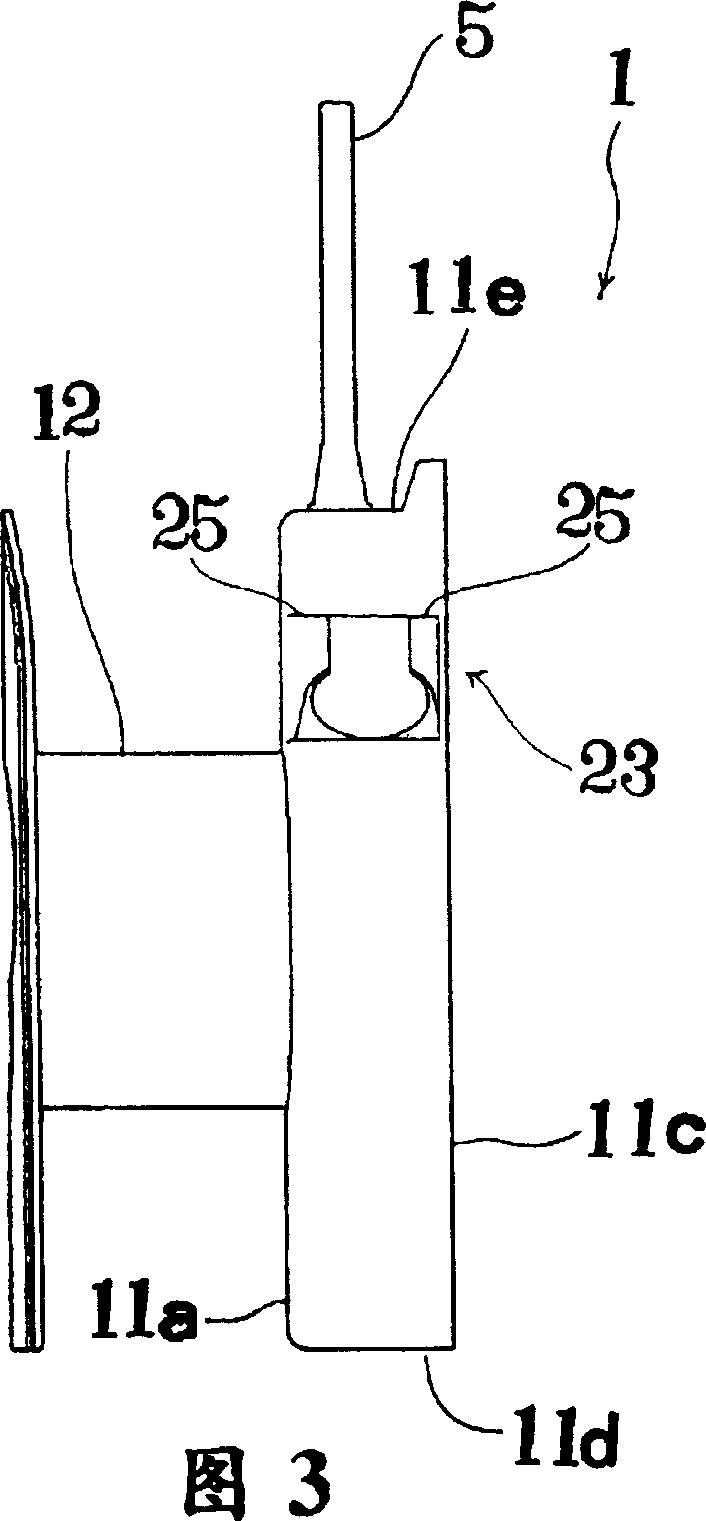

[0022] Such as Figure 1~6 As shown, the winding stand body 4 is a hollow cylindrical hose winding body 12 spanned approximately at the center of the front side wall body 10 and the rear side wall body 11 .

[0023] A spray gun storage portion 15 for storing the sprinkler gun 9 is formed in the hollow portion of the hose winding cylinder 12 .

[0024] The hose 2 is wound around the outer peripheral surface of the hose winding cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com