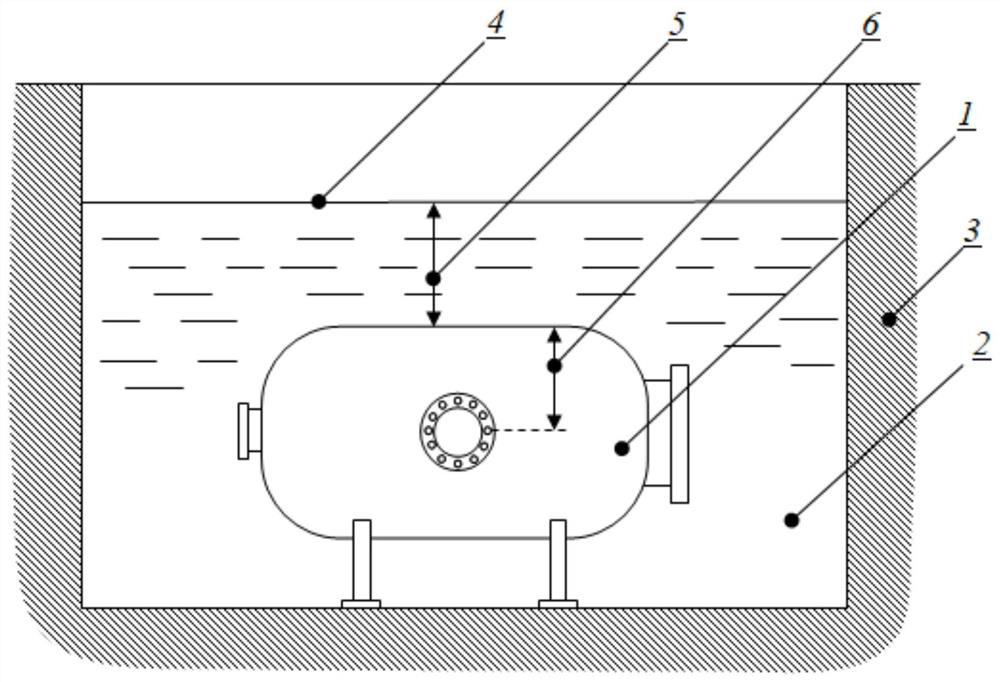

A method for protecting explosion containers with water

An explosion container and explosion test technology, which is applied in the direction of instruments, blasting, scientific instruments, etc., can solve the problems that are not conducive to the maintenance of the shell, and achieve the effects of easy conduction and transmission of shock waves, improving service life and ensuring environmental safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

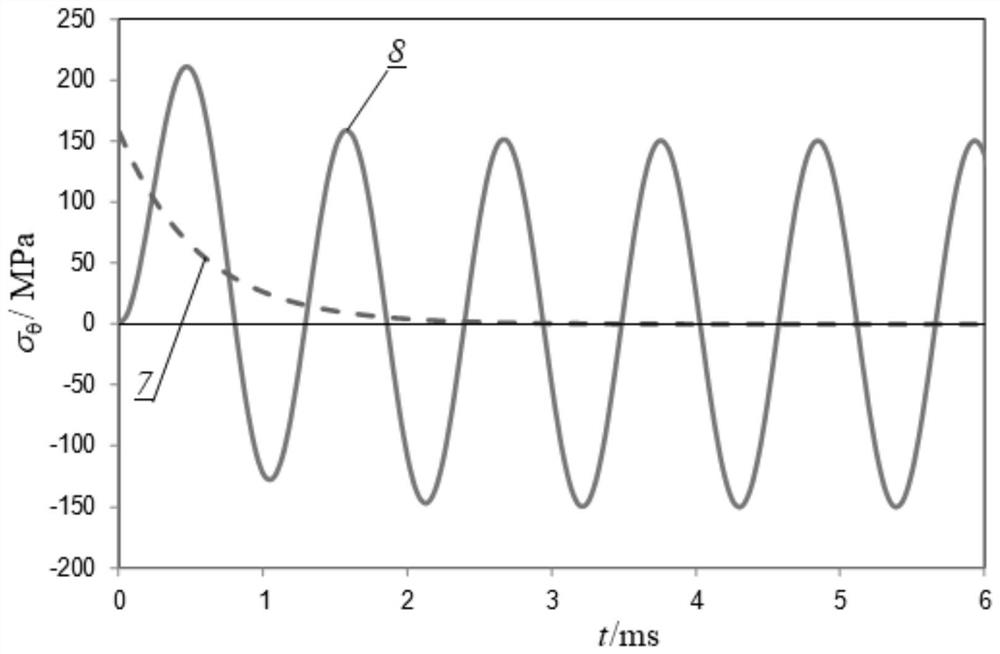

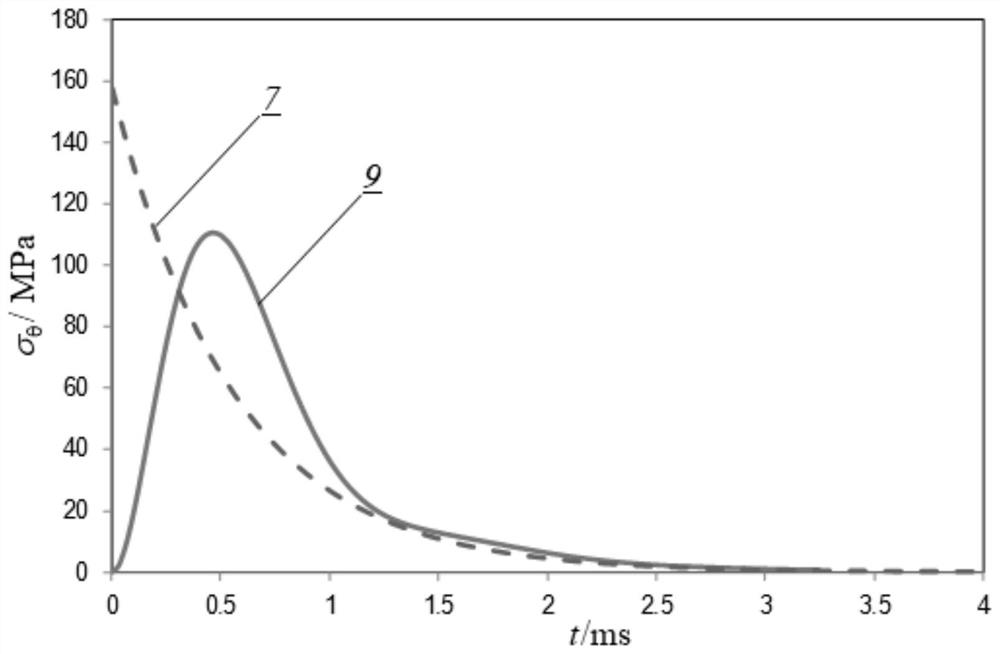

Embodiment 1

[0037] The actual explosion vessel of steel Q345A for the vessel is selected, and the vessel is designed as a spherical tank (n=2) with a radius R=1.5m, and the wall thickness δ is taken as 25mm (0.025m). The longitudinal wave sound velocity c of steel is 5123m / s, and the density ρ is 7 850kg / m 3 , Poisson's ratio μ is taken as 0.3; the sound velocity of water c 0 Take 1 480m / s, the density ρ 0 1 000kg / m 3 . Calculate the shell vibration circle frequency ω=5 773s by formula (3) -1 . The relative viscosity coefficient of water damping ζ = 0.5443, meeting the requirement of less than or equal to 0.25. The central explosion of the explosive with Q=5kgTNT equivalent is used for design, and the regular reflection shock wave load on the inner wall of the spherical shell is taken as

[0038] ΔP(t)=6.307×10 6 e -1786t (Pa)

[0039] Substituting the above parameters into formula (2), using the Duhamel integral method to solve the vibration equation of formula (2), it can be ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com