Method for producing p-acetamidobenzenesulfonyl chloride based on double-temperature-zone two-stage method of continuous flow reaction

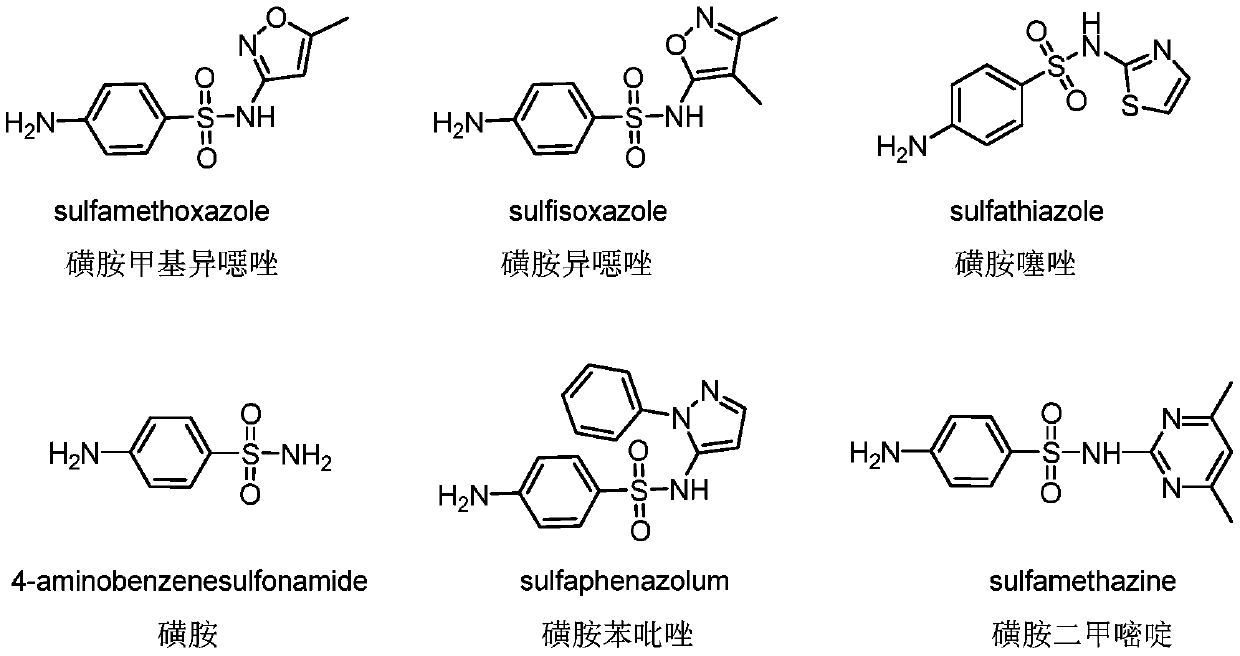

A technology of benzenesulfonyl chloride and acetamide, which is applied in the field of producing p-acetamidobenzenesulfonyl chloride by a two-stage two-stage method based on continuous flow reaction, and can solve the problems of increased by-products, increased by-products, decreased yield and the like , to improve the yield and selectivity, increase the reaction speed, and reduce the gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

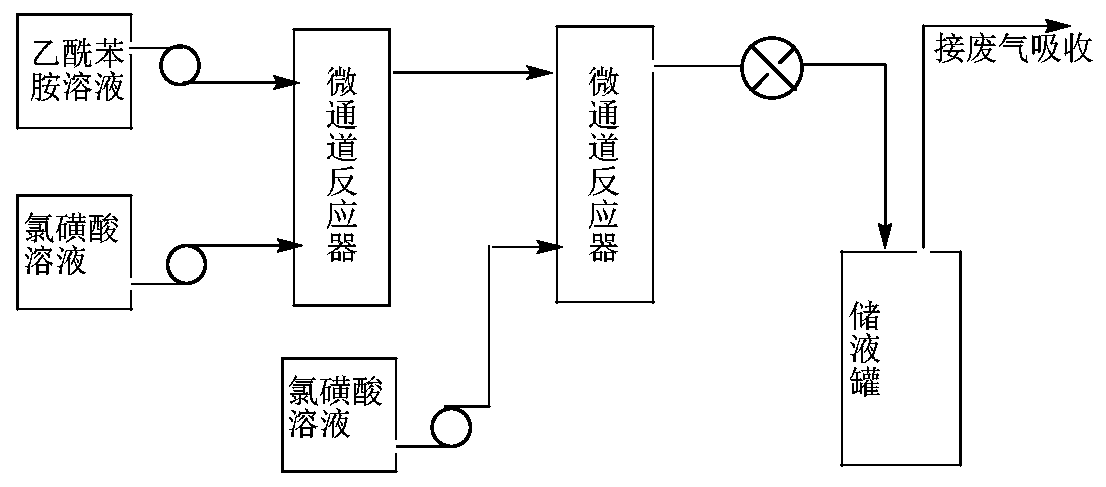

Method used

Image

Examples

Embodiment 1

[0018] Acetanilide (270.4 g, 2.0 mol) was dissolved in 1,2-dichloroethane (to make a solution (1200 mL).

[0019] Chlorosulfonic acid (582.7 g, 5.0 mol) and 1,2-dichloroethane were made into a solution (800 mL).

[0020] The temperature of the first group of microchannel reactors was adjusted to 25 degrees Celsius, and the temperature of the second group of microchannel reactors was adjusted to 75 degrees Celsius.

[0021] Adjust the discharge pressure of the back pressure valve to 1 atm.

[0022] Using 1,2-dichloroethane as solvent, calibrate the flow rate of the two injection pumps. Set the injection speed of the acetanilide solution to be 60mL / min, the experienced speed of the chlorosulfonic acid feed pump connected to the first group of microchannel reactors is 19mL / min, and connected to the second group of microchannel reactors The empirical speed of the chlorosulfonic acid feeding pump is 21mL / min. Respectively, take samples in 3 minutes and 10 minutes after the reacti...

Embodiment 2

[0025] Acetanilide (270.4 g, 2.0 mol) was dissolved in 1,2-dichloroethane to make a solution (1200 mL).

[0026] Chlorosulfonic acid (512.8 g, 4.4 mol) and 1,2-dichloroethane were made into a solution (800 mL).

[0027] The temperature of the first group of microchannel reactors was adjusted to 15 degrees Celsius, and the temperature of the second group of microchannel reactors was adjusted to 65 degrees Celsius.

[0028] Adjust the discharge pressure of the back pressure valve to 1 atm.

[0029] Using 1,2-dichloroethane as solvent, calibrate the flow rate of the two injection pumps. Set the injection speed of the acetanilide solution to be 60mL / min, the experienced speed of the chlorosulfonic acid feed pump connected to the first group of microchannel reactors is 19mL / min, and connected to the second group of microchannel reactors The empirical speed of the chlorosulfonic acid feeding pump is 21mL / min. Respectively, take samples in 3 minutes and 10 minutes after the reactio...

Embodiment 3

[0032] Acetanilide (270.4 g, 2.0 mol) was dissolved in 1,2-dichloroethane to make a solution (1200 mL).

[0033]Chlorosulfonic acid (652.7 g, 5.6 mol) and 1,2-dichloroethane were made into a solution (900 mL).

[0034] The temperature of the first group of microchannel reactors was adjusted to 15 degrees Celsius, and the temperature of the second group of microchannel reactors was adjusted to 80 degrees Celsius.

[0035] Adjust the discharge pressure of the back pressure valve to 1 atm.

[0036] Using 1,2-dichloroethane as solvent, calibrate the flow rate of the two injection pumps. Set the injection speed of the acetanilide solution to be 60mL / min, the experienced speed of the chlorosulfonic acid feed pump connected to the first group of microchannel reactors is 22mL / min, and the connected to the second group of microchannel reactors The experience speed of the chlorosulfonic acid feeding pump is 23mL / min. Respectively react 3 minutes, take a sample in 10 minutes, terminate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com