Intelligent lock test equipment

A test equipment and smart lock technology, which is applied in the testing of mechanical parts, environment/reliability testing, machine/structural parts testing, etc., can solve problems such as failure to test the life of smart locks, and achieve a comprehensive life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

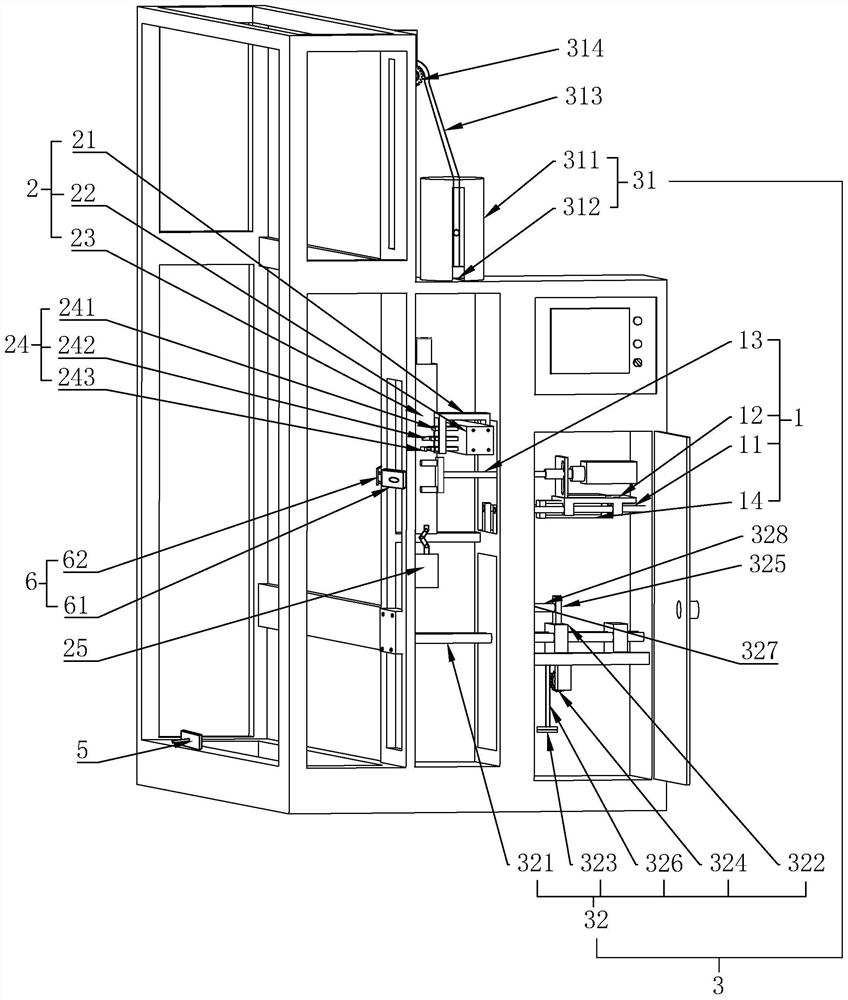

[0020]As an improved specific embodiment, the lower door opening assembly 32 includes a door opening lever 321, a door opening slide 322 and a door opening weight 323, the door opening slide 322 is fixedly installed in the control box, and one end of the door opening lever 321 Penetrate into the control box and pass through the door-opening slide 322 to be slidably arranged on the door-opening slide 322. The door-opening sprocket is rotatably connected to the position below the door-opening lever 321 in the control box. 324, the connecting piece 325 is fixed on the door opening lever 321, the door opening chain 326 is fixed on the lower side of the connecting piece 325, the upper end of the door opening chain 326 is connected on the lower side of the connecting piece 325, and the lower end bypasses the door opening sprocket After 324, it is connected with the door-opening weight 323. The control box is fixed with a reset cylinder 327 relative to the position above the door-open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com