Insulator wire fixing and lifting device

A wire fixing and wire lifting technology, applied in the direction of hoisting device, overhead line/cable equipment, clockwork mechanism, etc., can solve the problem of increasing the labor intensity of aerial workers, reducing the safety factor of aerial work, and affecting the construction efficiency of wire racks. and other problems, to achieve the effect of convenient modular storage, convenient disassembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

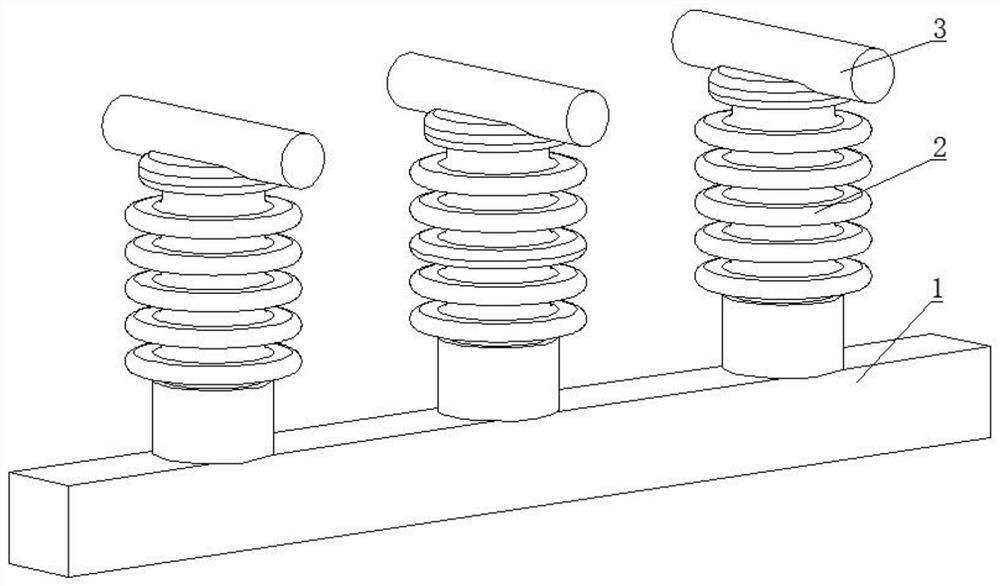

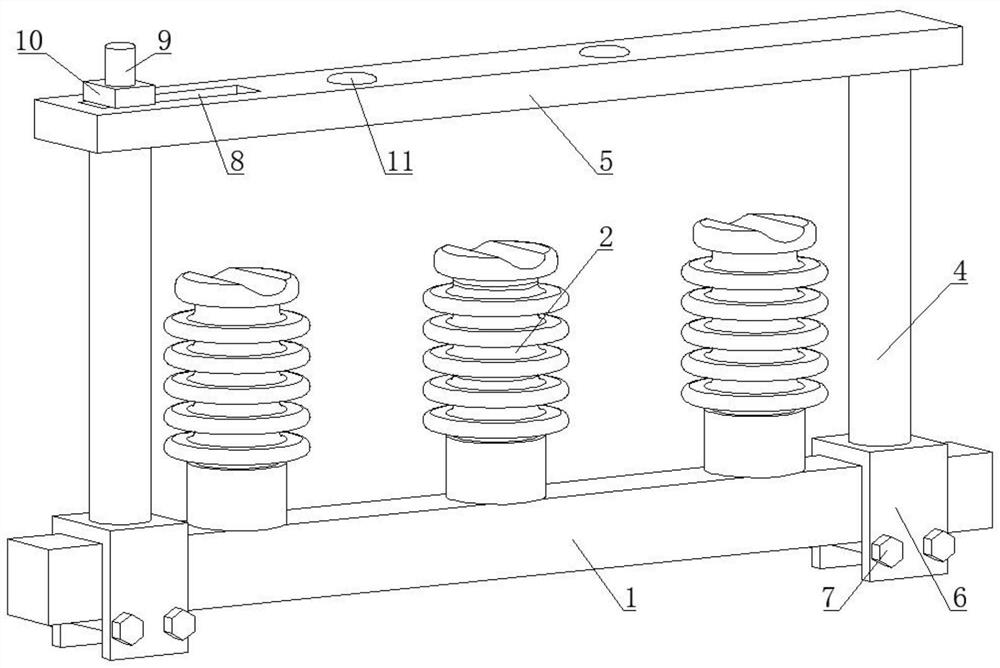

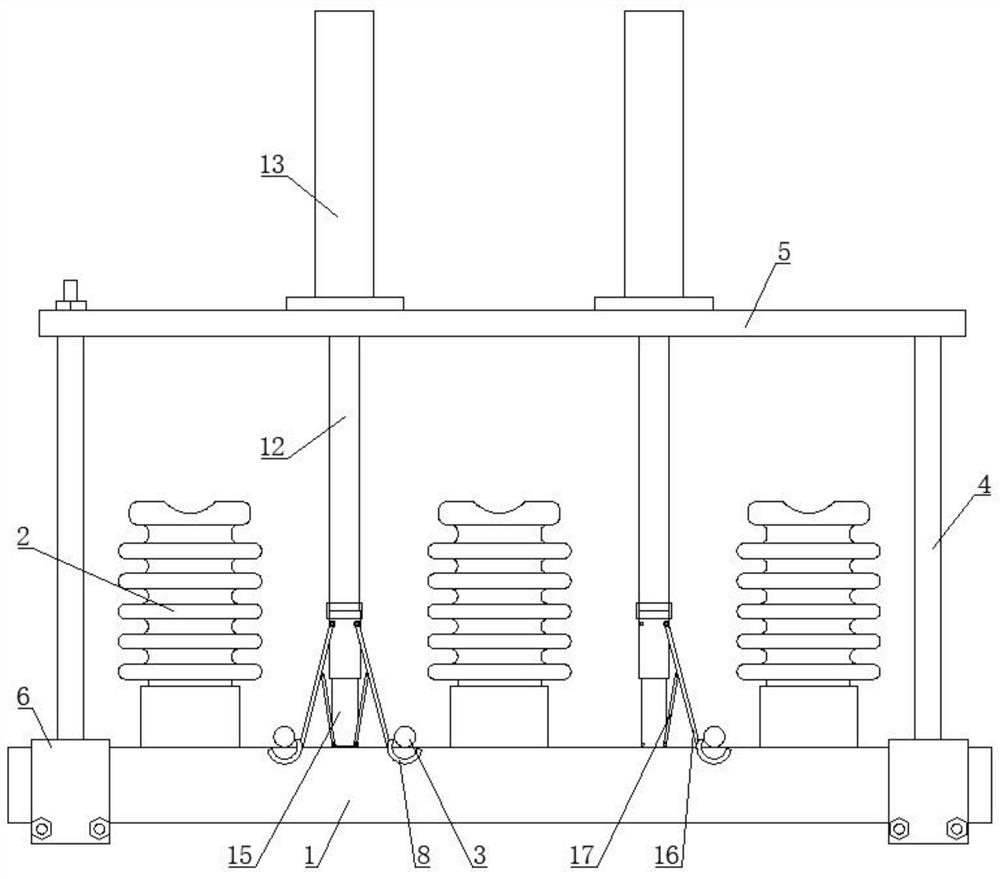

[0029] As shown in the drawings, an insulator wire fixing and lifting device includes a cross arm 1, an insulator 2, an upright lifting rod 12 and a "冂"-shaped bracket, and the insulator 2 is vertically installed on the upper side of the cross arm 1 , and three are arranged side by side at intervals for supporting and fixing the wires; the bracket includes a horizontal horizontal frame 5 and two vertical columns 4, and the horizontal frame 5 and the vertical columns 4 form a "冂"-shaped bracket, the The upright column 4 is detachably connected and installed with the end of the cross arm 1 through a connecting piece. The horizontal frame 5 is provided with a lifting device that drives the lifting rod 12 to lift. The guide hole 11 for the lifting guide of the rod 12, the lifting rod 12 is arranged in the middle of the adjacent insulator 2; the lower end of the lifting rod 12 is connected with a supporting telescopic cylinder 15, and the upper part of the cylinder body of the suppo...

Embodiment 2

[0039] Such as Figure 9 As shown, this embodiment is basically the same as Embodiment 1, the difference is that: the lifting device is a screw lifter 21, the lifting rod 12 is a threaded rod, and the screw lifter 21 is provided with a rocker 22. Rotate the rocker 22, drive the lifting rod 12 to go up and down through the screw lifter 21, the transmission is stable and reliable, and can be rotated manually, the operation is convenient, time-saving and labor-saving; safety.

[0040] In the initial state of the insulator wire fixing and lifting device, the lifting rod is in the state of descending and extending, the supporting telescopic cylinder is in the state of extending, and the wire lifting hook is at the lower side of the corresponding wire; the lifting device drives the lifting rod to lift, and the wire lifting hook is aligned with the wire. The support lifts up until it is higher than the insulator; the support telescopic cylinder retracts, driving the support rod to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com