Rotor dismounting method and device

A technology in a rotor and a stator, applied in the field of rotor disassembly and installation, can solve the problems of permanent magnet damage of the rotor, collision between the stator and the rotor, and can not be reused.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

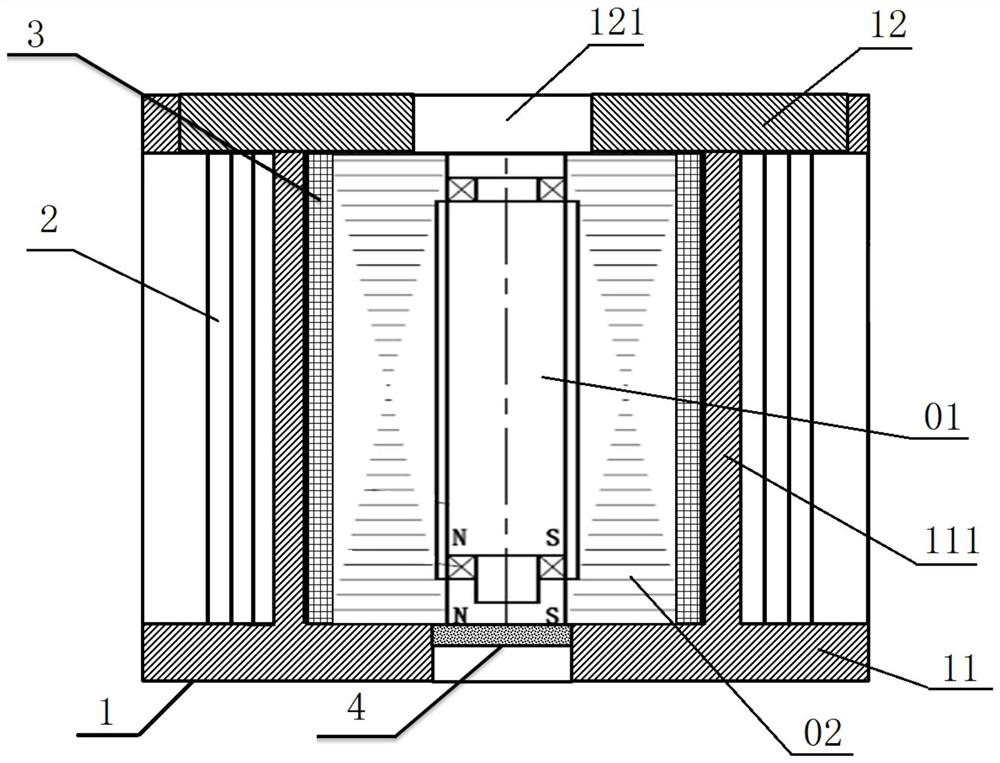

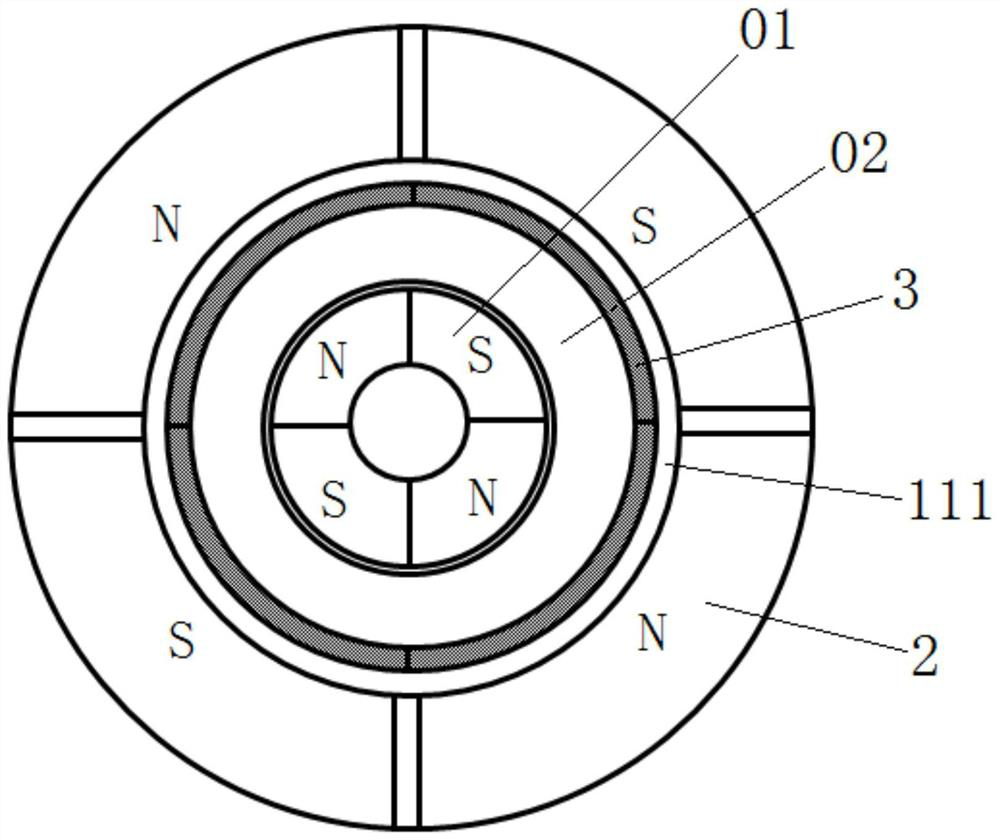

[0067] like figure 1 , figure 2 As shown, the device includes a fixing tool 1 , a radial magnetic force offset unit 2 , a sensor unit 3 , and an axial magnetic force action unit 4 .

[0068] The fixed tooling 1 includes a bracket 11 and a cover plate 12 provided with a central hole 121. The bracket 11 includes an inner barrel 111 for placing the motor to be disassembled. The cover plate 12 is arranged above the bracket 11. The central hole 121 is just in front of the motor to be disassembled to remove the end cover. One end, and the diameter of the central hole 121 is larger than the outer diameter of the rotor 01 of the motor to be disassembled, and smaller than the outer diameter of the stator 02 of the motor to be disassembled, which is used to limit the axial movement of the stator 02, and the rotor 01 can be taken out through the central hole 121.

[0069] The radial magnetic force offset unit 2 includes n tile-shaped magnetic body assemblies, and the n tile-shaped magn...

Embodiment 2

[0078] see figure 1 , figure 2 As shown, the device includes a fixing tool 1 , a radial magnetic force offset unit 2 , a sensor unit 3 , and an axial magnetic force action unit 4 .

[0079] The fixed tooling 1 includes a bracket 11 and a cover plate 12 provided with a central hole 121. The bracket 11 includes an inner barrel 111 for placing the motor to be disassembled. The cover plate 12 is arranged above the bracket 11. The central hole 121 is just in front of the motor to be disassembled to remove the end cover. One end, and the diameter of the central hole 121 is larger than the outer diameter of the rotor 01 of the motor to be disassembled, and smaller than the outer diameter of the stator 02 of the motor to be disassembled, which is used to limit the axial movement of the stator 02, and the rotor 01 can be taken out through the central hole 121.

[0080] The radial magnetic force offset unit 2 includes n tile-shaped electromagnets, and the n tile-shaped electromagnets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com