Composition of environmental glass used for TFT-LCDs

A glass, environmental protection technology, applied in the field of environmental glass composition, can solve the problem of reducing the expansion rate of glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

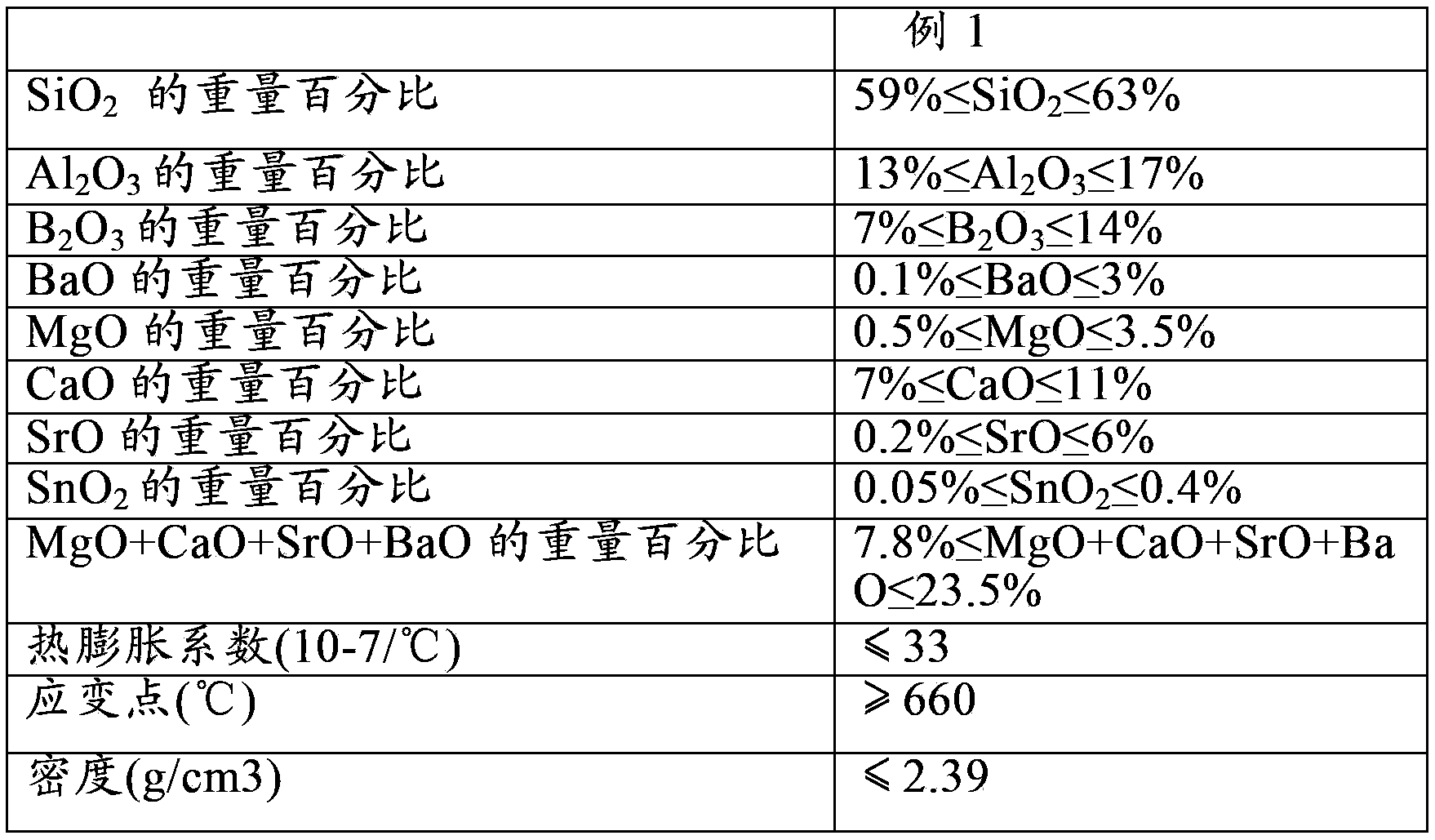

[0013] The present invention mainly provides a composition of environmental protection glass for TFT-LCD, which is It is composed of the following materials according to a certain weight percentage:

[0014] (1)59.0%≤SiO 2 ≤63.0%;

[0015] (2) 13.0%≤Al 2 O 3 ≤17.0%;

[0016] (3)7.0%≤B 2 O 3 ≤14%;

[0017] (4) 0.1%≤BaO≤3%;

[0018] (5) 0.5%≤MgO≤3.5%;

[0019] (6) 7%≤CaO≤11%;

[0020] (7) 0.2%≤SrO≤6%; and

[0021] (8) The total weight percentage of components such as CaO, BaO, MgO and SrO is 7.8% to 23.5%.

[0022] In the present invention, the weight percentage of each composition will affect the characteristics, structure and production of the environmental protection glass for TFT-LCD to varying degrees according to its physical properties. Therefore, the weight percentage of each composition is must be limited, where SiO 2 , Al 2 O 3 and B 2 O 3 These three components account for a large percentage by weight, and their effects on the characteristics, struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strain point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com