Fire nozzle with floor type bracket

A floor stand and water gun technology, which is applied in fire rescue and other directions, can solve problems such as excessive force, falling on the ground, and displacement of the support, so as to improve service life, reduce contact friction, and improve stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

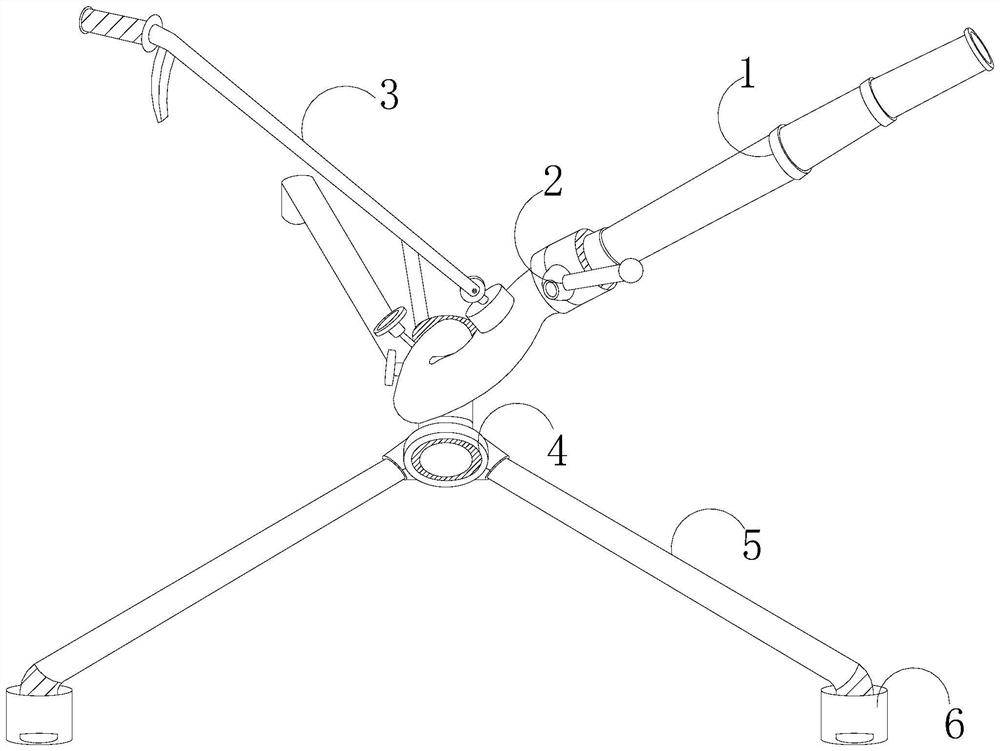

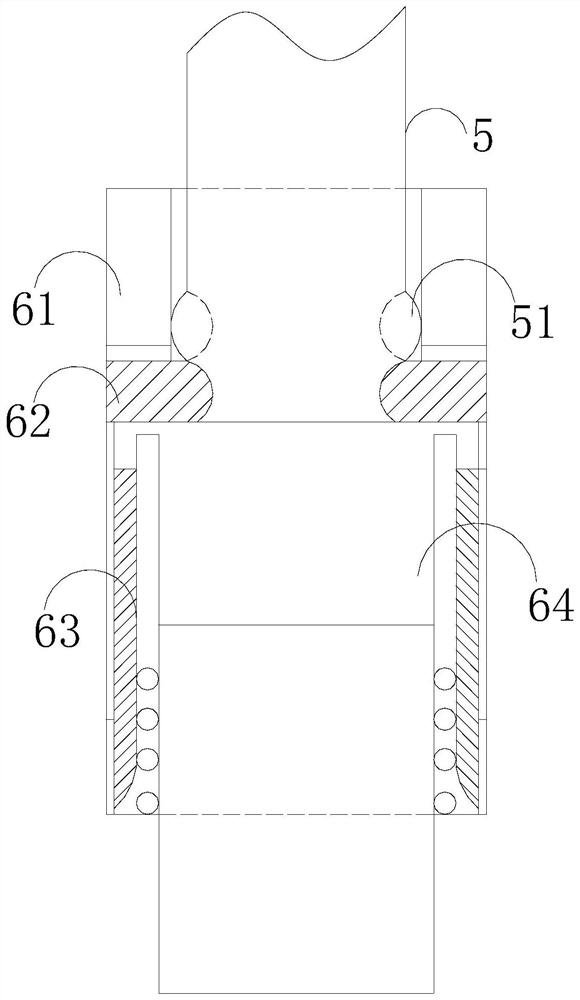

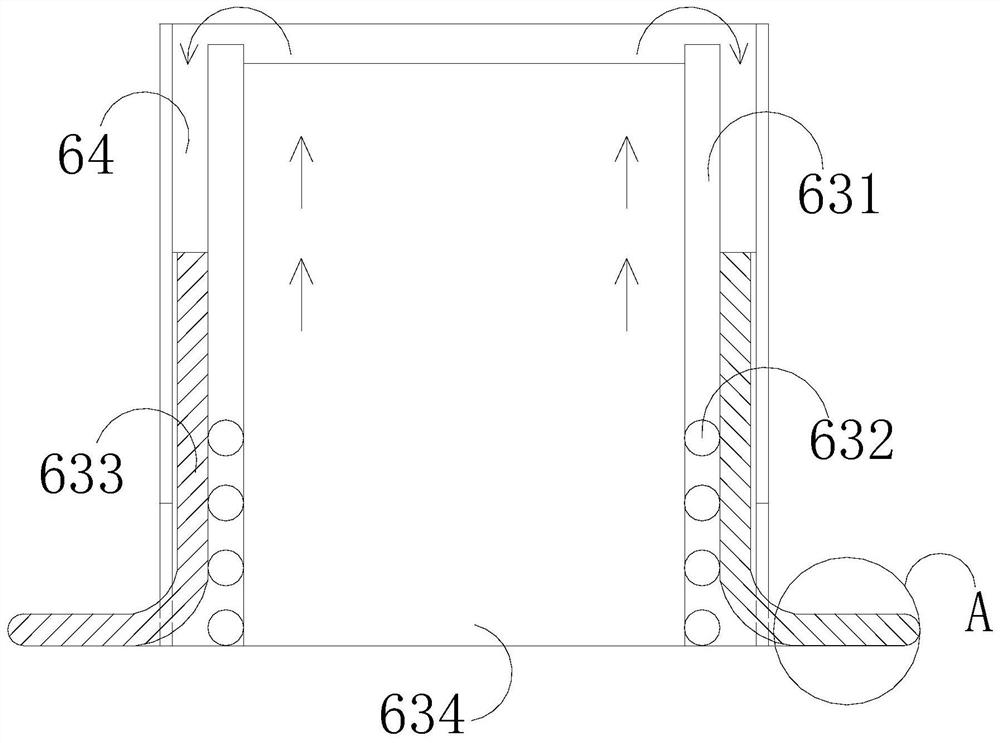

[0028] Such as Figure 1-Figure 6 As shown, the present invention provides a fire-fighting water gun with a floor-standing bracket, and its structure includes a water gun connecting rod 1, a control switch 2, a handle 3, a connecting shaft 4, a foot 5, and a foot cover 6. A control switch 2 is installed, the connecting rod 1 of the water gun is connected with the supporting foot 5 by a connecting shaft 4, the surface of the connecting rod 1 of the water gun is mechanically connected with a handle 3, and the bottom of the supporting leg 5 is provided with a foot cover 6, One end of the support foot 5 passing through the fixing device 6 is provided with a telescopic card slot 51, and the foot cover 6 includes a limit sliding edge 61, a block 62, a ground sticking device 63, and a pressure chamber 64. The limit sliding edge 61 In contact with the telescopic card slot 51, the bottom of the limit sliding edge 61 is provided with a block 62, the block 62 is welded on the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com