A heat treatment method for controlling microstructure and microhardness of near-β titanium alloy

A heat treatment method and microstructure technology are applied in the field of titanium alloy processing to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] After the Ti-7333 alloy after billet forging was subjected to solid solution treatment at 900°C / 30min (the temperature of the heat treatment furnace was 900°C, and the holding time was 30min), a sample was formed. The microstructure of the sample was as follows: figure 1 , where the tissue feature is full-β tissue with isometric tissue features.

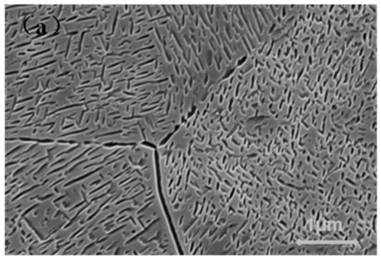

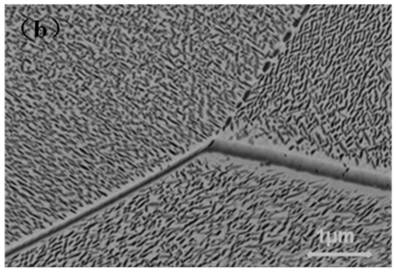

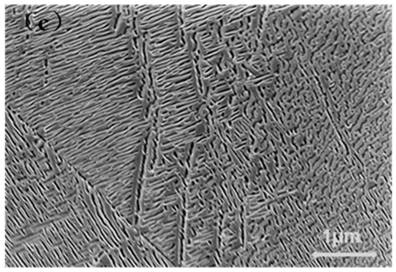

[0047] Then the sample is raised from room temperature to 700°C at a heating rate of 5°C / min, and different elastic tensile stresses are applied to the sample. At this time, the microstructure of the sample is as follows: Figure 2-4 shown, where figure 2 is the microstructure characteristics of the sample (Ti-7333 alloy) in the unstressed state, image 3 is the microstructure characteristics of the sample (Ti-7333 alloy) under the state of 20MPa tensile stress, Figure 4 It is the microstructure characteristics of the sample (Ti-7333 alloy) under the state of 20MPa compressive stress.

[0048] No elastic stress is applied...

Embodiment 2

[0050] After the Ti-7333 alloy that has been forged by blanking is subjected to solution treatment at 900°C / 30min (the temperature of the heat treatment furnace is 900°C, and the holding time is 30min), the sample is formed, and then the sample is heated at a heating rate of 10°C / min. Raise to 700°C, and apply different elastic tensile stresses to the sample; among them, such as Figure 5 Shown is the microstructure characteristics of the sample (Ti-7333 alloy) under no stress; as Figure 6 Shown is the microstructure characteristics of the sample (Ti-7333 alloy) under the action of 20MPa compressive stress; as Figure 7 Shown is the microstructure characteristics of the sample (Ti-7333 alloy) under the action of 50MPa compressive stress.

[0051] Such as Figure 5 The grain size of the short rod-shaped α phase precipitated in the stress-free state is about 218-425 μm; Figure 6 As shown, under the action of 20MPa compressive stress, in the direction parallel to the applied...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com