Tooth-shaped step surface beam body structure under large gradient condition

A step surface and large slope technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as unstable structures and affecting the safety of superstructures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in combination with specific embodiments.

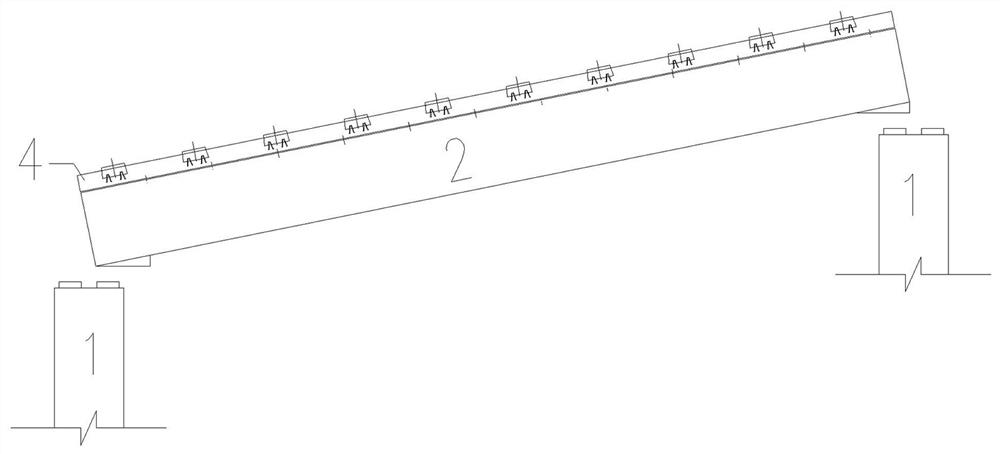

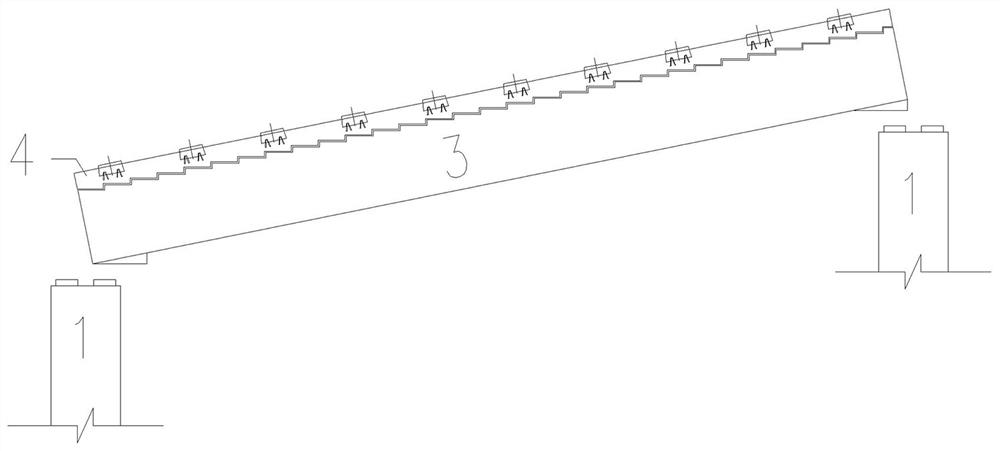

[0029] The invention relates to a toothed step surface beam structure under the condition of a large slope, the structure includes upright piers 1 at the upper and lower ends, and a longitudinal toothed step surface beam body 3 is carried above the two ends of the pier 1, and the toothed step surface A track bed 4 is arranged above the beam body 3 .

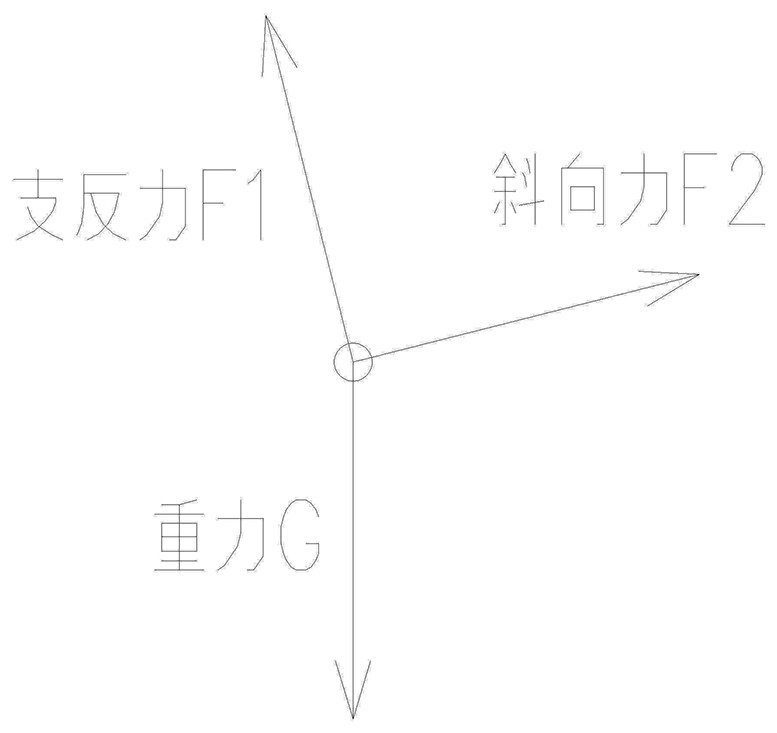

[0030] The surface of the tooth-shaped stepped beam body 3 is uniformly provided with a transverse strip-shaped tooth structure. The bar-shaped tooth structure on the surface of the tooth-shaped step surface beam body 3 is arranged horizontally or segmentally at intervals. The bar-shaped tooth structure on the surface of the toothed stepped surface beam body 3 has two contact surfaces, one contact surface is a horizontal surface, the other contact surface is a vertical surface, or both contact surfaces are inclined surfaces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com