Thin film sensing structure, temperature sensor and electronic equipment

A technology for temperature sensors and electronic equipment, applied in thermometers, thermometers using directly heat-sensitive electrical/magnetic components, thermometer parts, etc. The problem of increasing the probability of cracks, etc., to achieve the effect of stable signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The embodiments of the present invention are described in detail below. The embodiments described with reference to the accompanying drawings are exemplary. The embodiments of the present invention are described in detail below.

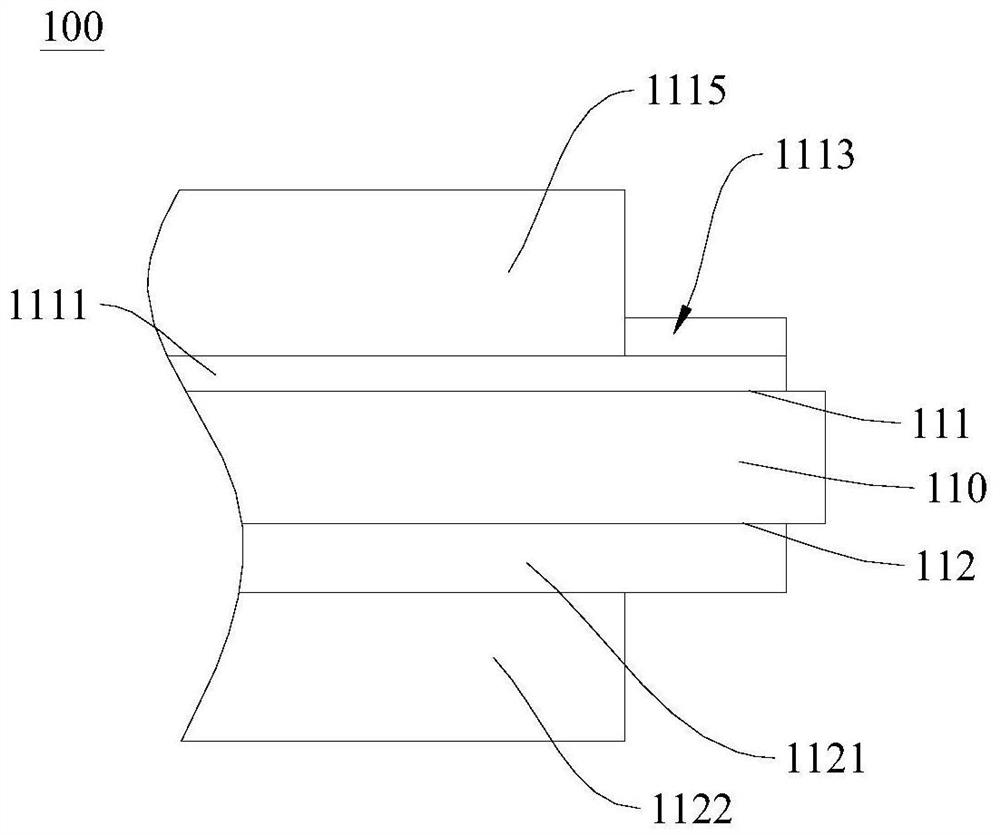

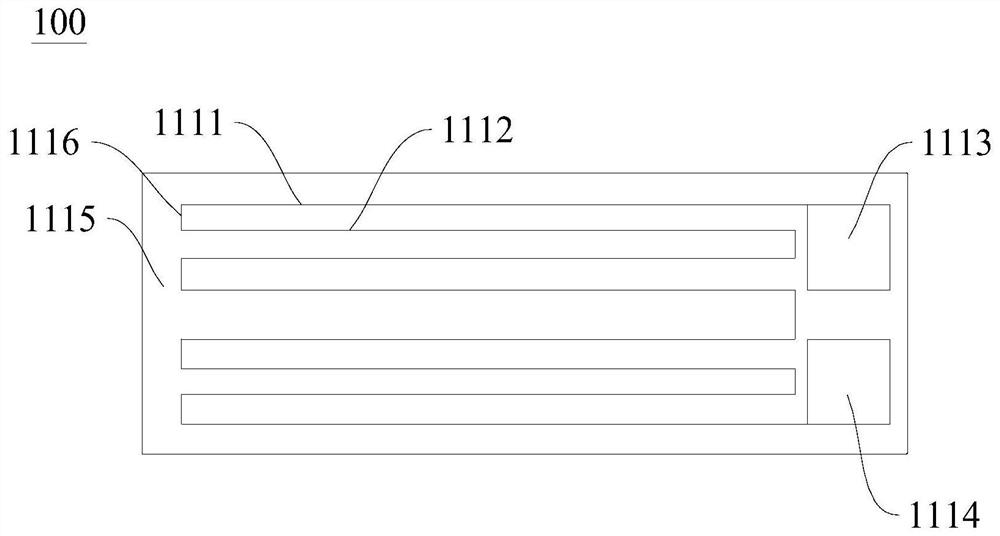

[0024]Reference belowFigure 1-Figure 2The thin film sensing structure 100 according to an embodiment of the present invention is described, including a substrate 110.

[0025]Specifically, the substrate 110 has a first surface 111, and a first metal circuit 1111 and a second metal circuit 1112 are provided on the first surface 111. One end of the first metal circuit 1111 and the second metal circuit 1112 are connected to form a thermoelectric junction 1116. The other end of the first metal circuit 1111 is connected to the first binding block 1113, the other end of the second metal circuit 1112 is connected to the second binding block 1114, the first binding block 1113 and the second binding block 1114 are used for external circuits, The first metal line 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com