Contact carrier for providing electrical contact for wiring in a vehicle

A carrier and contact technology, applied in the direction of vehicle connectors, vehicle components, connections, etc., to achieve the effect of stable displacement movement, eliminating the need for complex fastening, and simple displacement movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

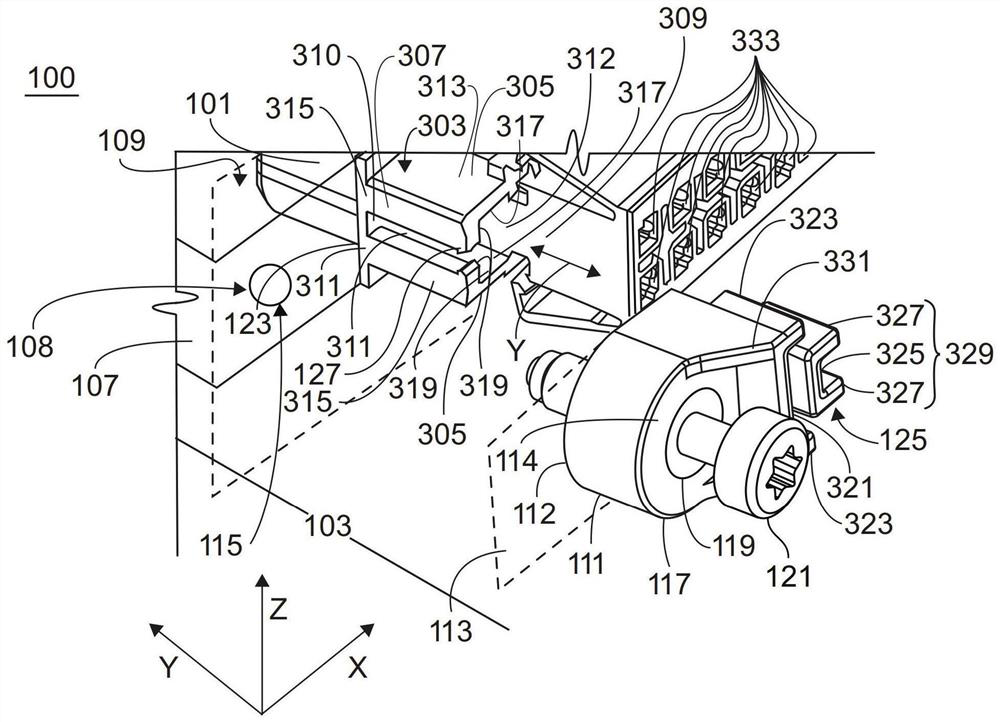

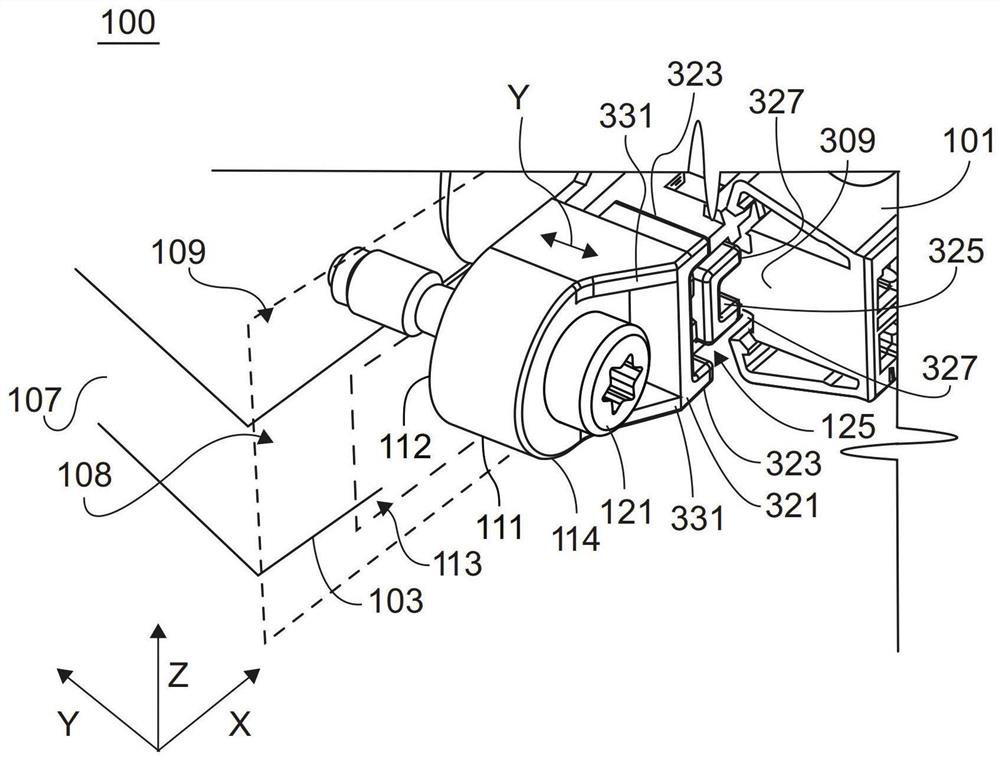

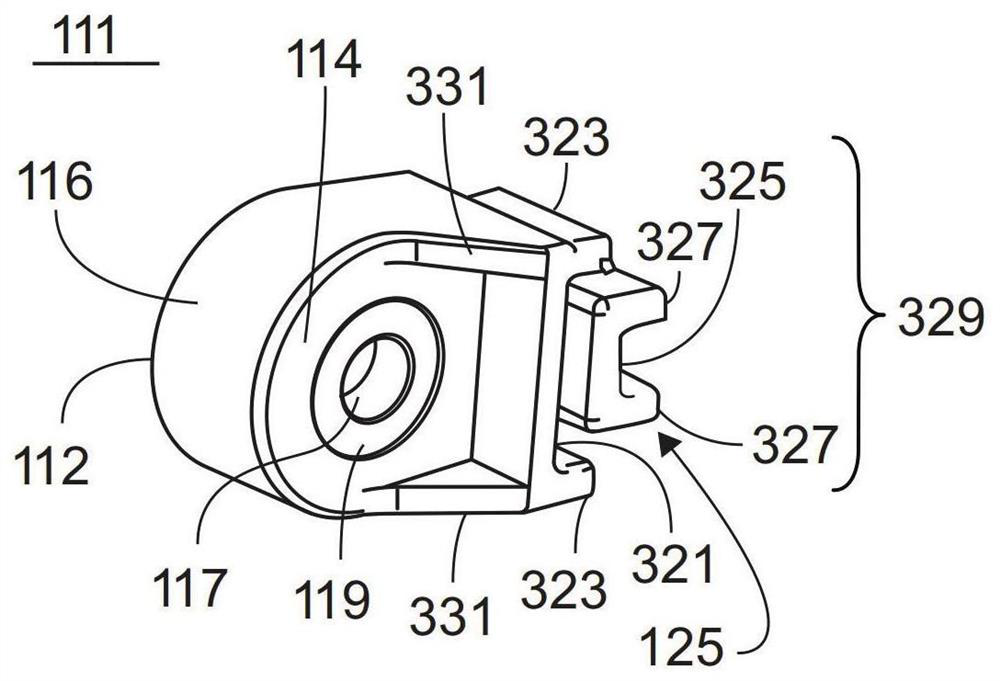

[0076] figure 1 A schematic cross-sectional view of a contact carrier 100 according to an embodiment is shown with a carrier body 101 , a first clamping element 107 and a second clamping element 111 , wherein the second clamping element 111 is released from the carrier body 101 .

[0077] For better understanding, combine Figure 6 and Figure 7 The contact carrier 100 in the figure 1 and figure 2 The contact carrier 100 in.

[0078] according to figure 1 , providing a contact carrier 100 for providing contact for wiring in a vehicle and comprising: a carrier body 101 for receiving a plurality of contacts; at least one fastening element 103 for fastening the carrier body 101 to a carrier element 105 ; wherein the fastening element 103 includes: a first clamping element 107, connected to the carrier body 101; a second clamping element 111, displaceably formed on the carrier body 101 and opposite to the first clamping element 107, and locking means 121 for locking the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com