Automatic stringing method of power line pole

A technology for power line poles and wires, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of overall operation trouble, energy consumption, requirements, etc., and achieve the effect of improving efficiency and safety, and saving labor and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

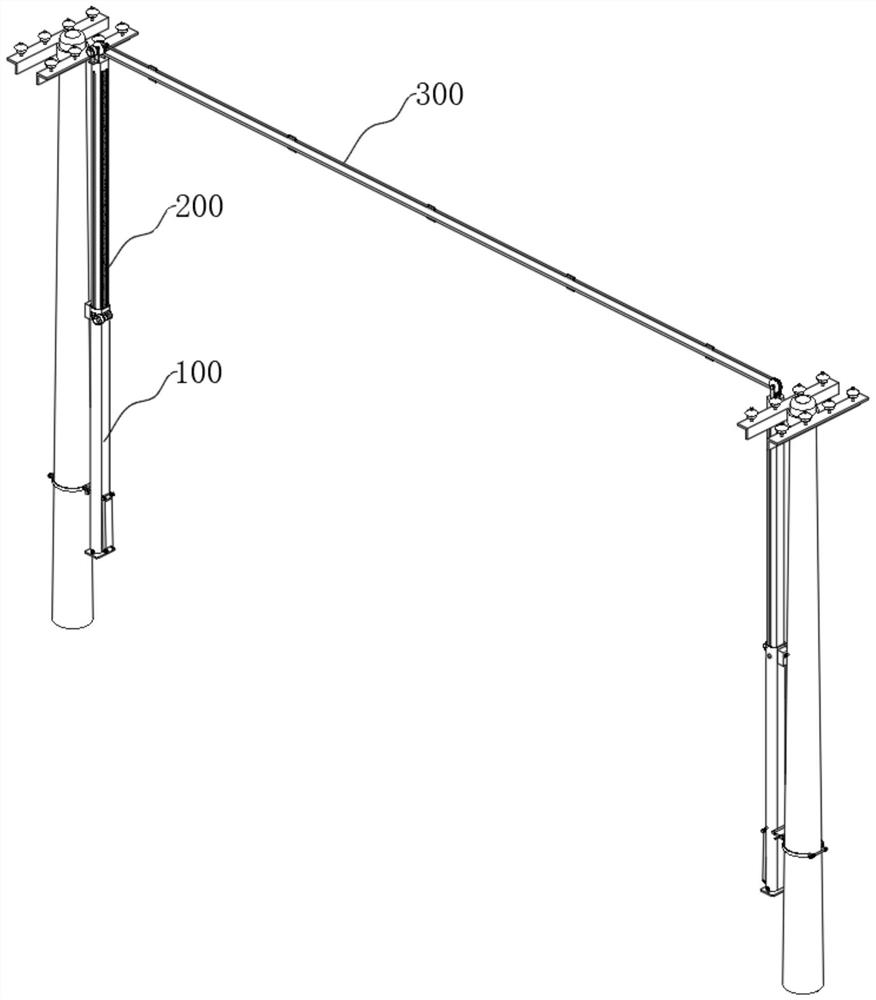

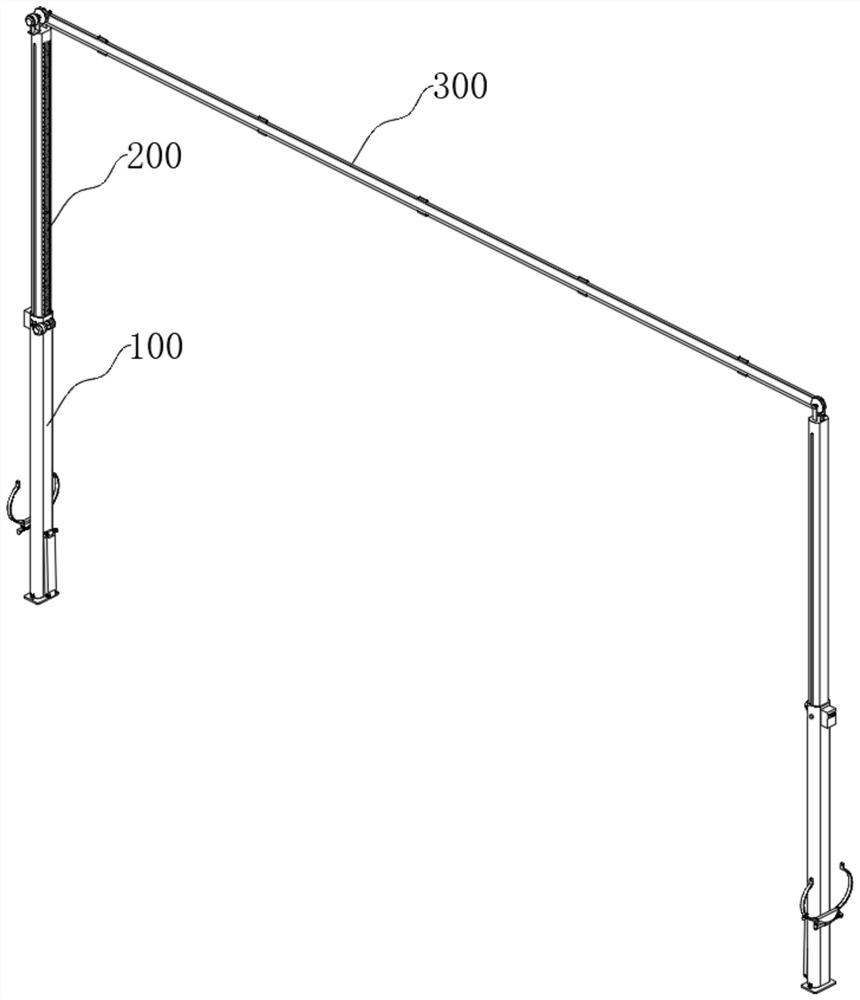

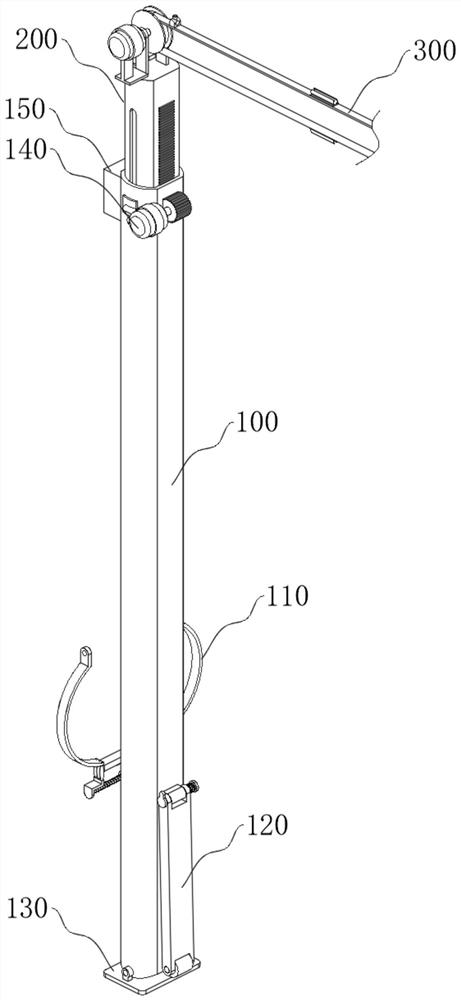

[0060] The invention provides a method for automatic wiring of a power line pole, comprising the following steps:

[0061] 1. The erection pipe is moved to the power line pole stage:

[0062] S1. First take out a pair of stringing pipes 100 of the automatic stringing equipment for power line poles, then move the rotating pin 124 outward, and rotate the moving rod 120 to a suitable deployment angle, and then loosen the rotating pin 124 to reset it. Make the moving rod 120 be limited and fixed;

[0063] S2. Then carry the line pipe 100, and make the rubber wheel 122 roll in contact with the ground, then move the two line pipes 100 to the side of two adjacent power line poles, and make the binding mechanism 110 face the power line rod;

[0064] S3, then hold the main ring 111 on the binding mechanism 110 and turn it to the power pole. Under the linkage cooperation between the linkage rod 1121 and the jack 1114, the main ring 111 and the secondary ring 112 move closer to each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com