Efficient processing method of pig feed

A processing method and pig feed technology, applied in feed, chemical instruments and methods, mixers, etc., can solve problems such as poor feed mixing effect, achieve good mixing treatment, good mixing effect, and improved production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

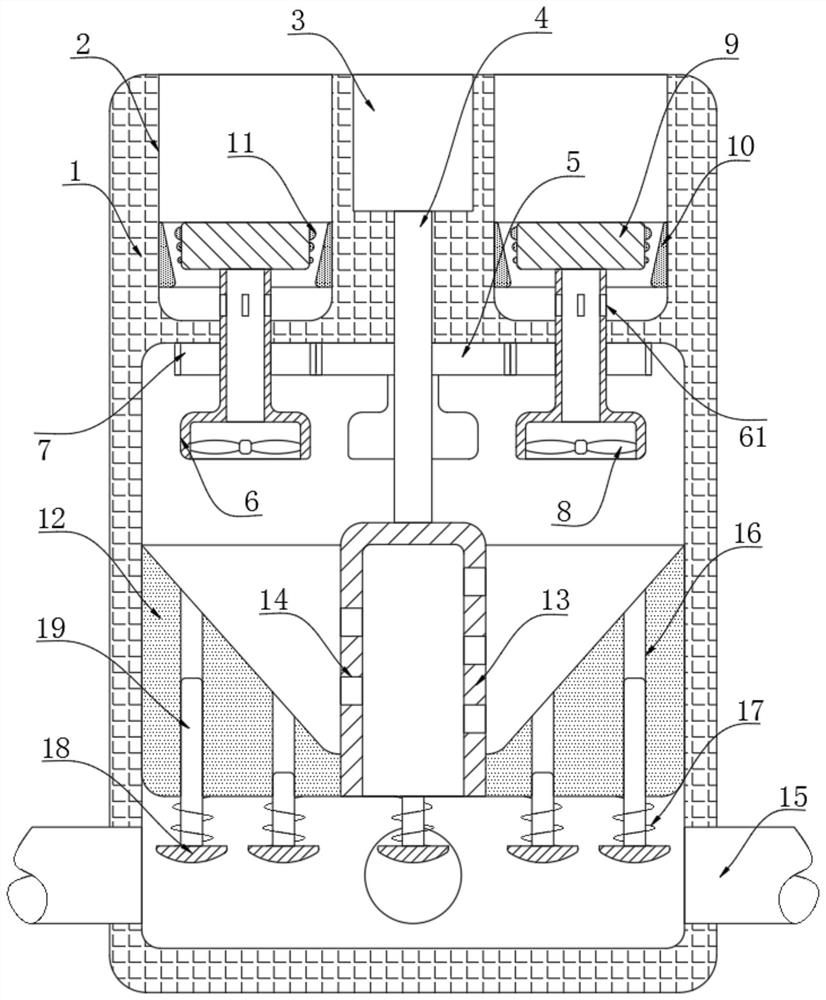

[0023] refer to Figure 1-2 , a method for efficiently processing pig feed, mainly comprising the following processing steps:

[0024] S1. Feed and electrify: Place the various raw materials required for mixing in multiple raw material tanks 2, start the motor 3 and the external pulse fan, and separate the main mixed raw materials in the raw material tanks 2 at the diagonal position, increasing the overall efficiency. mixing effect;

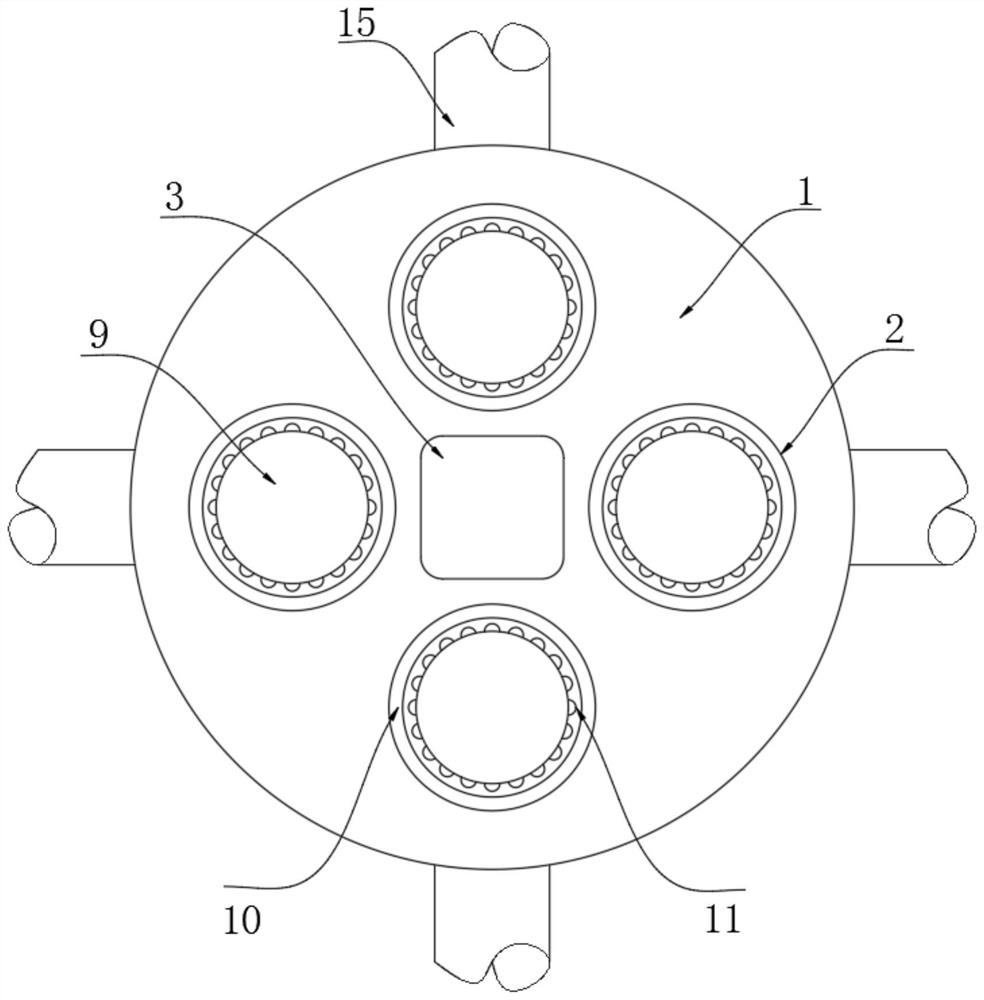

[0025] S2. Grinding and mixing of raw materials: The grinding disc 9 is rotated through the meshing transmission of the driving gear 5 and the driven gear 7, so that the raw material is refined by friction and extrusion with the grinding ring 10 under the drive of the grinding disc 9, so that large-grained raw materials Powdering to improve the overall mixing effect, the powdered raw materials are sucked by the wind generated by the rotation of the rotor 8, and sprayed into the processing box 1 through the grinding shaft 6, and the effective mix...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap