A kind of n, s co-doped porous carbon-coated carbon nanotube bifunctional oxygen electrode catalyst and preparation method

A technology of porous carbon and coated carbon, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of poor controllability of doping atomic structure, inability to incorporate heteroatoms, and complicated preparation process To solve the problems such as chemistry and other problems, the preparation process is green and pollution-free, which is beneficial to large-scale application and has low toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

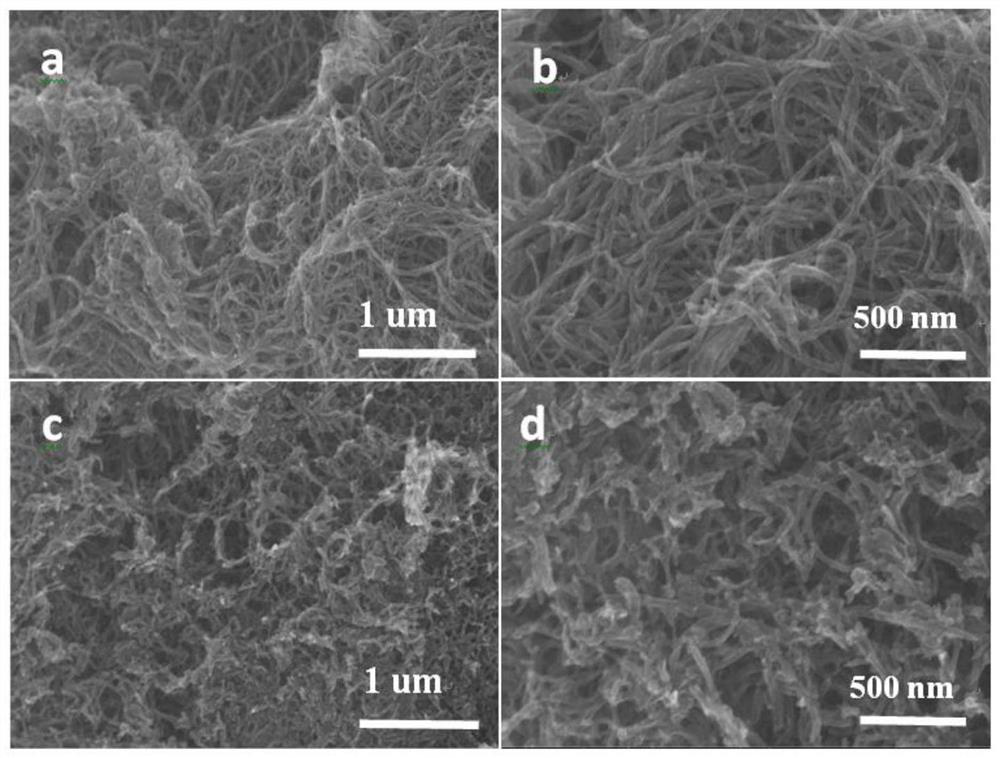

[0045] Example 1: N 1 C-CNT-900-2(N 1 In C-CNT-900-2, 1 means that the mass ratio of aniline in the raw material to the carbon substrate is 1, 900 means that the calcination temperature is 900°C, and 2 means that the calcination time is 2h)

[0046] Add 0.05g CNT to 100mL 0.2mol / L HCl, then add 0.05mL AN, and ultrasonicate for 30min to form a uniform mixed solution A, wherein the mass concentration of CNT is 0.0005g mL -1 ; 0.0625g (NH 4 ) 2 S 2 o 8 Add to 20mL 0.2mol / L HCl, ultrasonic 10min, form uniform mixed solution B, wherein, (NH 4 ) 2 S 2 o 8 The mass concentration is 0.003125g mL -1 . Then put the mixed solution A into the ice-water bath, control the temperature at 0-10°C, and stir in the ice bath for 30 minutes, then drop the B solution into the mixed solution A drop by drop, and continue to stir in the ice bath for 30 minutes after the dripping, and the stirring rate is uniform. It is 25r / min. Finally, the mixture was sealed and placed in a refrigerator f...

Embodiment 2

[0048] Example 2: N 2 C-CNT-900-2(N 2 The first 2 in C-CNT-900-2 indicates that the mass ratio of aniline in the raw material to the carbon substrate is 2, 900 indicates that the calcination temperature is 900°C, and the second 2 indicates that the calcination time is 2h)

[0049] Add 0.05g CNT to 100mL 0.2mol / L HCl, then add 0.10mL AN, and sonicate for 30min to form a uniform mixed solution A, wherein the mass concentration of CNT is 0.0005g mL -1 ; 0.125g (NH 4 ) 2 S 2 o 8 Add to 20mL 0.2mol / L HCl, ultrasonic 10min, form uniform mixed solution B, wherein, (NH 4 ) 2 S 2 o 8 The mass concentration is 0.00625g mL -1 . Then put the mixed solution A into the ice-water bath, control the temperature at 0-10°C, and stir in the ice bath for 30 minutes, then drop the B solution into the mixed solution A drop by drop, and continue to stir in the ice bath for 30 minutes after the dripping, and the stirring rate is uniform. It is 25r / min. Finally, the mixture was sealed and p...

Embodiment 3

[0051] Example 3: N 4 C-CNT-900-2(N 2 In C-CNT-900-2, 4 means that the mass ratio of aniline in the raw material to the carbon substrate is 4, 900 means that the calcination temperature is 900°C, and 2 means that the calcination time is 2h)

[0052] Add 0.05g CNT to 100mL 0.2mol / L HCl, then add 0.20mL AN, and ultrasonicate for 30min to form a uniform mixed solution A, wherein the mass concentration of CNT is 0.0005g mL -1 ; 0.250g (NH 4 ) 2 S 2 o 8 Add to 20mL 0.2mol / L HCl, ultrasonic 10min, form uniform mixed solution B, wherein, (NH 4 ) 2 S 2 o 8 The mass concentration is 0.0125g mL -1 . Then put the mixed solution A into the ice-water bath, control the temperature at 0-10°C, and stir in the ice bath for 30 minutes, then drop the B solution into the mixed solution A drop by drop, and continue to stir in the ice bath for 30 minutes after the dripping, and the stirring rate is uniform. It is 25r / min. Finally, the mixture was sealed and placed in a refrigerator for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com