Efficient energy-saving sand making device

A high-efficiency, energy-saving, mounting frame technology, applied in grain processing, etc., can solve the problems of inconvenient operation and high energy consumption of transportation, achieve the effect of reducing operation intensity, reducing complicated process, and improving the efficiency of sand making treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

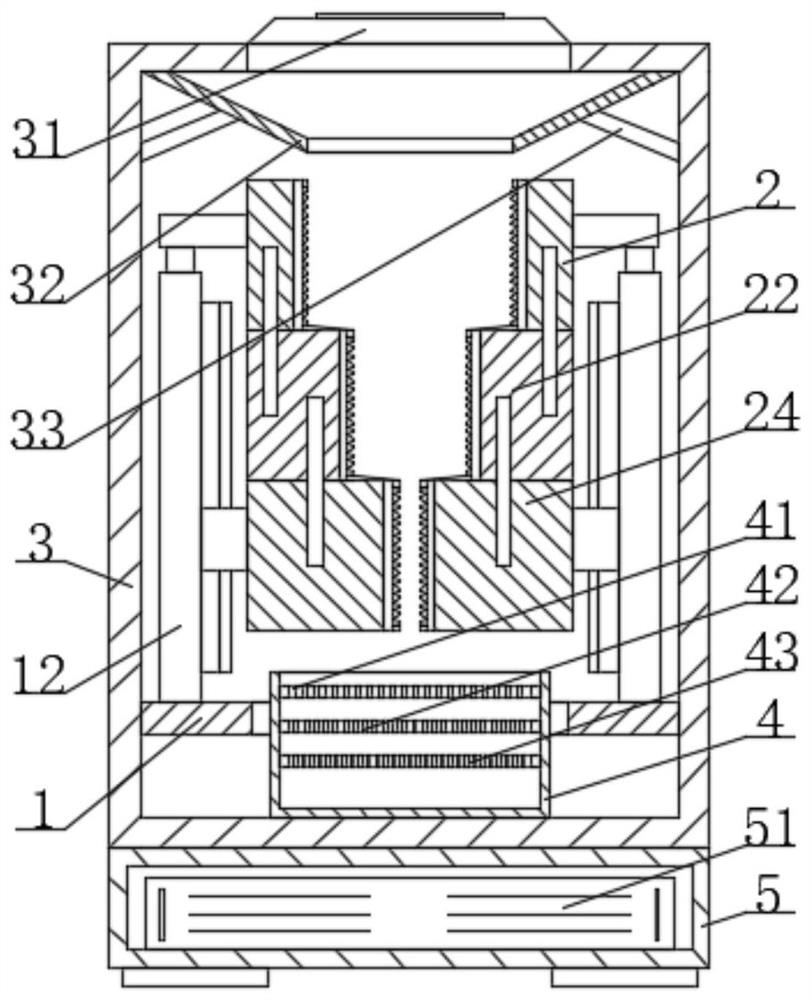

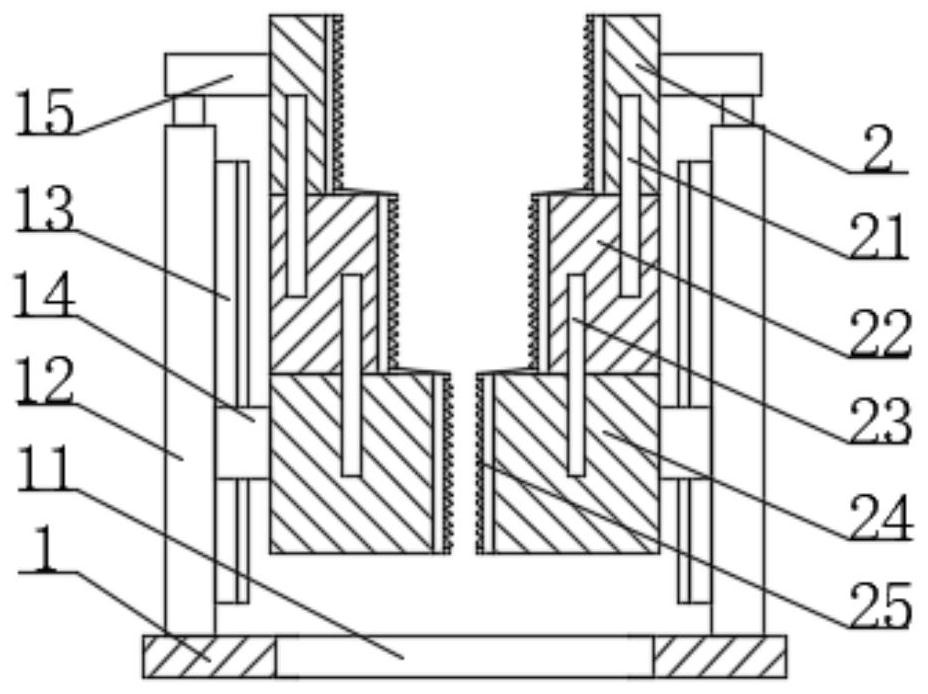

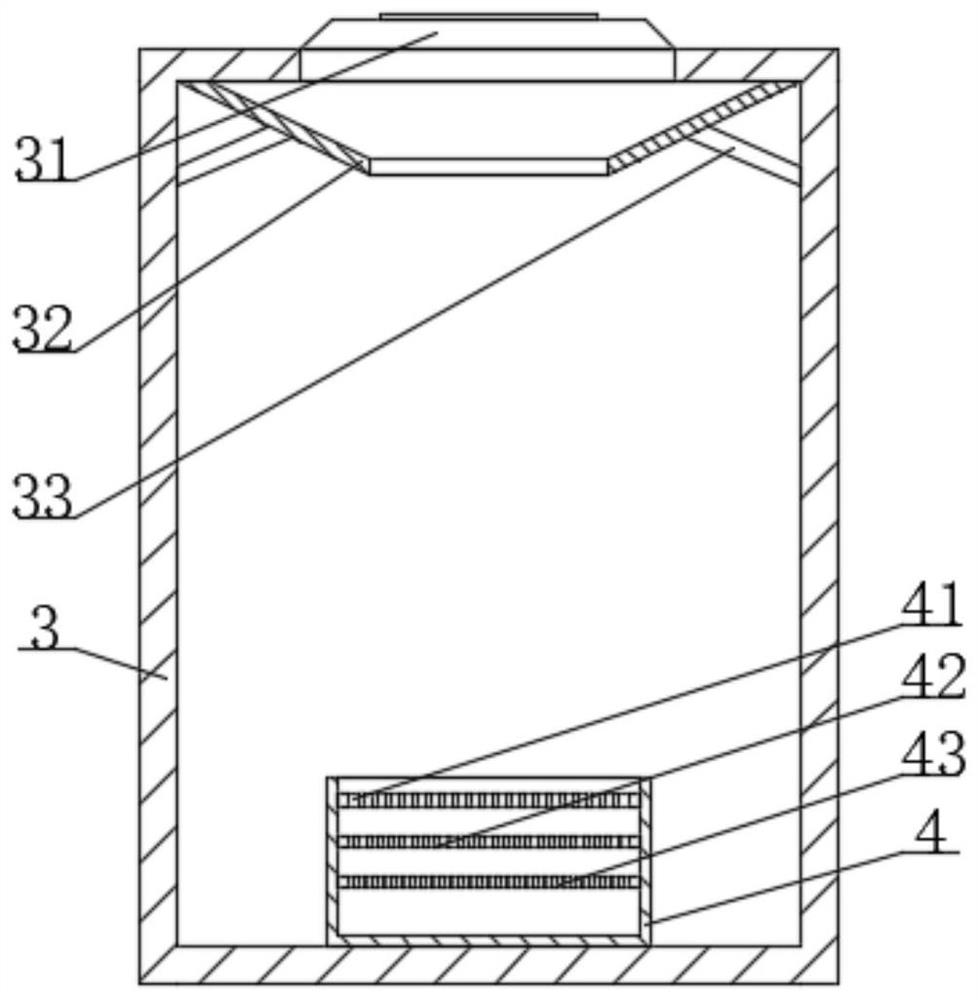

[0023] see Figure 1-5 , the present invention provides a technical solution: a high-efficiency energy-saving sand making device, including a mounting frame 1 and a connecting piece 2, a feeding hole 11 is opened in the middle of the mounting frame 1, through which the crushed material can be effectively made The output of the rocks is convenient for users to collect. The middle part of the upper surface of the installation frame 1 is connected to the electro-hydraulic push rod 12 by bolts near the two ends, and the power output end of the electro-hydraulic push rod 12 is connected to a fixed block by bolts. 15. The electro-hydraulic push rod 12 can effectively drive the fixed block 15 to move in a directional manner, and the adjacent ends of the two fixed blocks 15 are fixedly connected to the connecting piece 2 by bolts, and the connecting block 2 has a square prism structure, so The bottom end of the connecting piece 2 is fixedly connected with a locating piece 22 by bolts,...

Embodiment 2

[0025] see Figure 1-5 , the present invention provides a technical solution: a high-efficiency energy-saving sand making device, including a mounting frame 1 and a connecting piece 2, a feeding hole 11 is opened in the middle of the mounting frame 1, through which the crushed material can be effectively made The output of the rocks is convenient for users to collect. The middle part of the upper surface of the installation frame 1 is connected to the electro-hydraulic push rod 12 by bolts near the two ends, and the power output end of the electro-hydraulic push rod 12 is connected to a fixed block by bolts. 15. The electro-hydraulic push rod 12 can effectively drive the fixed block 15 to move in a directional manner, and the adjacent ends of the two fixed blocks 15 are fixedly connected to the connecting piece 2 by bolts, and the connecting block 2 has a square prism structure, so The bottom end of the connecting piece 2 is fixedly connected with a locating piece 22 by bolts,...

Embodiment 3

[0027] see Figure 1-5, the present invention provides a technical solution: a high-efficiency energy-saving sand making device, including a mounting frame 1 and a connecting piece 2, a feeding hole 11 is opened in the middle of the mounting frame 1, through which the crushed material can be effectively made The output of the rocks is convenient for users to collect. The middle part of the upper surface of the installation frame 1 is connected to the electro-hydraulic push rod 12 by bolts near the two ends, and the power output end of the electro-hydraulic push rod 12 is connected to a fixed block by bolts. 15. The electro-hydraulic push rod 12 can effectively drive the fixed block 15 to move in a directional manner, and the adjacent ends of the two fixed blocks 15 are fixedly connected to the connecting piece 2 by bolts, and the connecting block 2 has a square prism structure, so The bottom end of the connecting piece 2 is fixedly connected with a locating piece 22 by bolts, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com