U-shaped cutter of pulverizer

A pulverizer and cutter technology, applied in the field of pulverizer cutter structure, can solve the problems of unreasonable structure design, insufficient pulverized material precision, easy to stick to the bottom of the screen, etc., and achieve the effect of improving structural defects, avoiding the sticking of the bottom of the screen, and increasing the output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

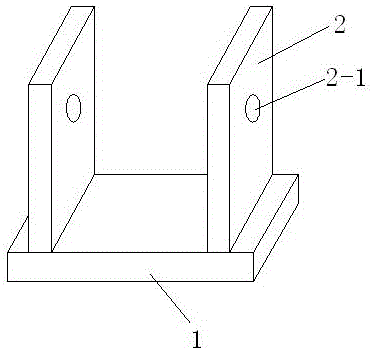

[0025] A U-shaped cutter of a pulverizer is movably installed on the rotating roller of the pulverizer. The overall shape of the U-shaped cutter is a U-shaped structure, and specifically includes: a tool holder 2 composed of two plate-shaped structures arranged in parallel longitudinally. The plate-like structure is respectively reserved with mounting shaft holes 2-1 with the axis on a straight line; a knife body 1 in a plate-like structure and installed transversely on the end of the tool holder 2 away from the mounting shaft hole 2-1, so The cutter body can be cut into a steel plate with the same width by using an old automobile spring steel plate without teeth or other tools. The cutter body 1 and the two plate-shaped structures of the cutter holder 2 are vertically fixedly connected. The structure of the two plates constituting the tool rest 2 uses two iron plates with a thickness of 4-5 mm. The tool rest cannot be made of steel plate, because the steel plate is brittle and...

Embodiment 2

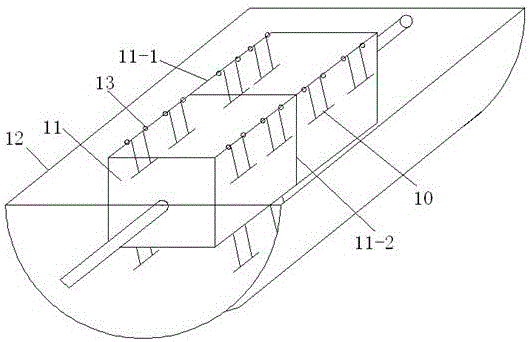

[0028] The pulverizer includes a rotating roller 11 installed on the frame, and a screen 12 located at the lower part of the rotating roller 11, and a U-shaped cutter 10 is installed on the rotating roller 11;

[0029] The tool 10 is composed of a tool holder 2 and a tool body 1; the tool holder 2 is composed of two plate-shaped structures arranged side by side in a longitudinal direction, and the two plate-shaped structures are respectively reserved for installation of shaft centers on a straight line. Shaft hole 2-1; the knife body 1 is a plate-shaped structure, which is installed transversely to the end of the knife holder 2 away from the mounting shaft hole 2-1, the knife body 1 and the two plates of the knife holder 2 Vertically fixed connection between the shaped structures. The two plate structures that make up the tool holder 2 are made of two 4-5mm thick iron plates; the plate structure that makes up the knife body 1 is made of steel; the difference between the tool hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com