Three-point truss type girder bridge intelligent steel diaphragm

A type of diaphragm beam and truss technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problem that the bridge cannot meet the strength requirements of the diaphragm beams, the welding quality of the diaphragm beams is poor, and the diaphragm beams are not coplanar, etc. problems, to achieve the effect of improving structural defects, avoiding construction difficulties, and reducing construction difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

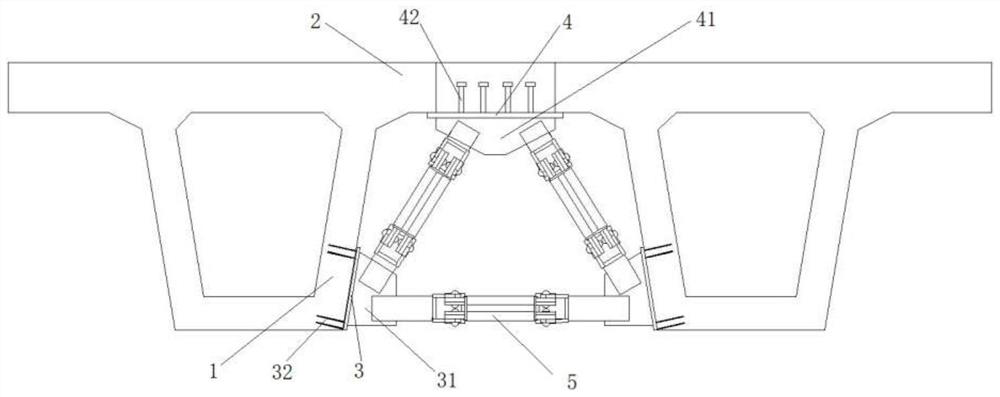

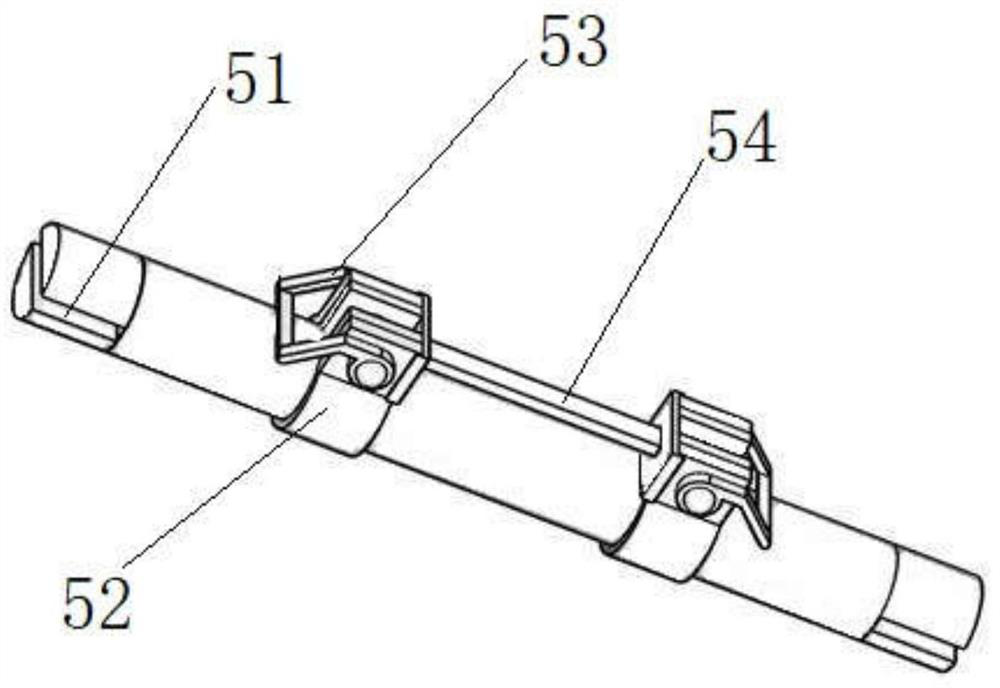

[0030] Such as Figure 1~3 As shown, a smart steel diaphragm of a three-point truss girder bridge is installed between the webs 1 of two adjacent small box girders or T-beams, including two pre-buried at the bottom of the adjacent webs 1 The lower steel plate 3, a top steel plate 4 pre-embedded in post-cast concrete between adjacent beam flanges 2, and three supporting steel pipes 5 respectively cooperating with the lower steel plate 3 and the top steel plate 4 to form a triangular support structure.

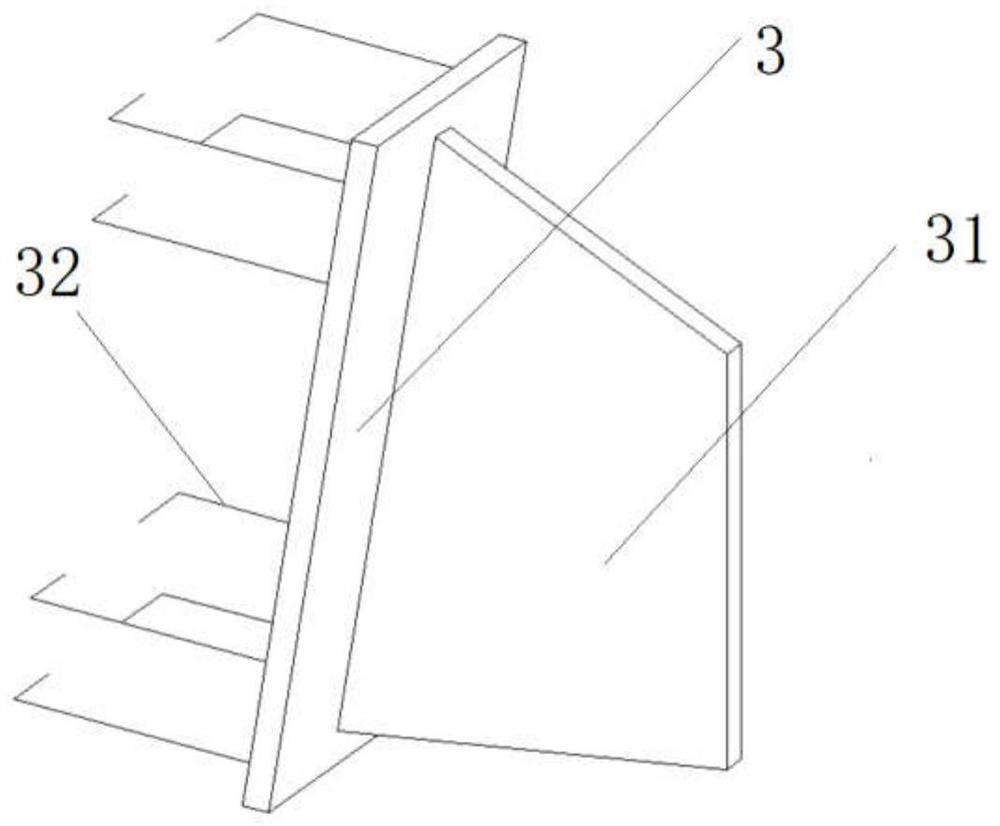

[0031] Specifically, such as figure 2 As shown, the lower steel plate 3 is vertically provided with a gusset plate 31 , and at the same time, the lower steel plate 3 is pre-embedded at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com