Tea sorting system and method

A sorting system and tea technology, applied in chemical instruments and methods, solid separation, tea treatment before extraction, etc., can solve the problems of poor sorting effect, complex structure, low sorting efficiency, etc., to facilitate collection, improve The effect of screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

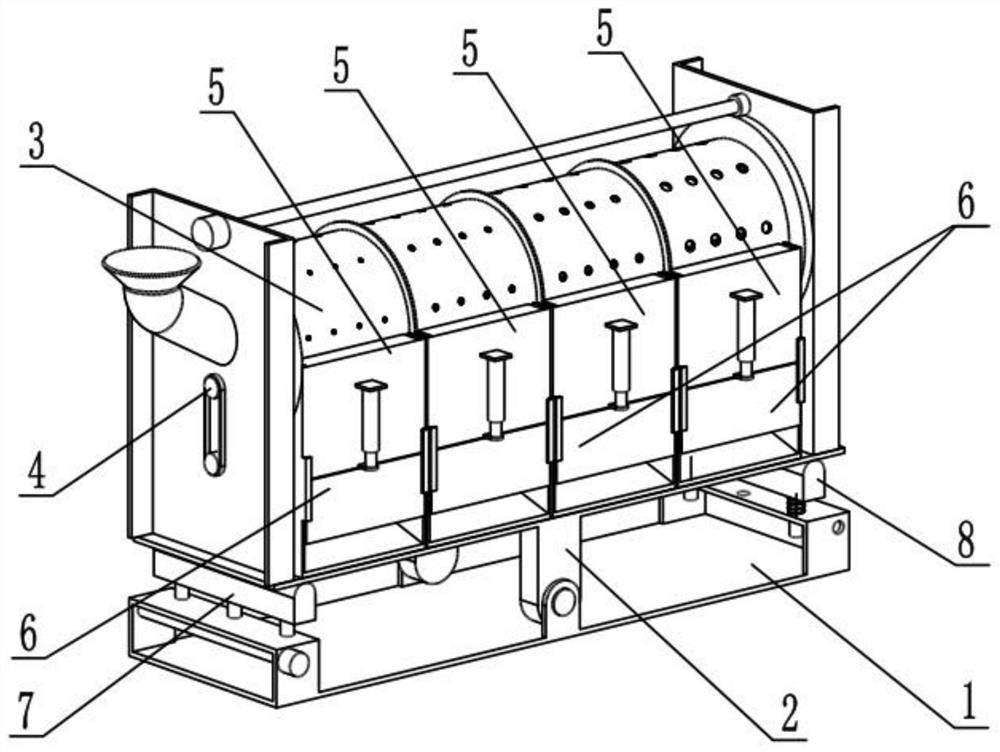

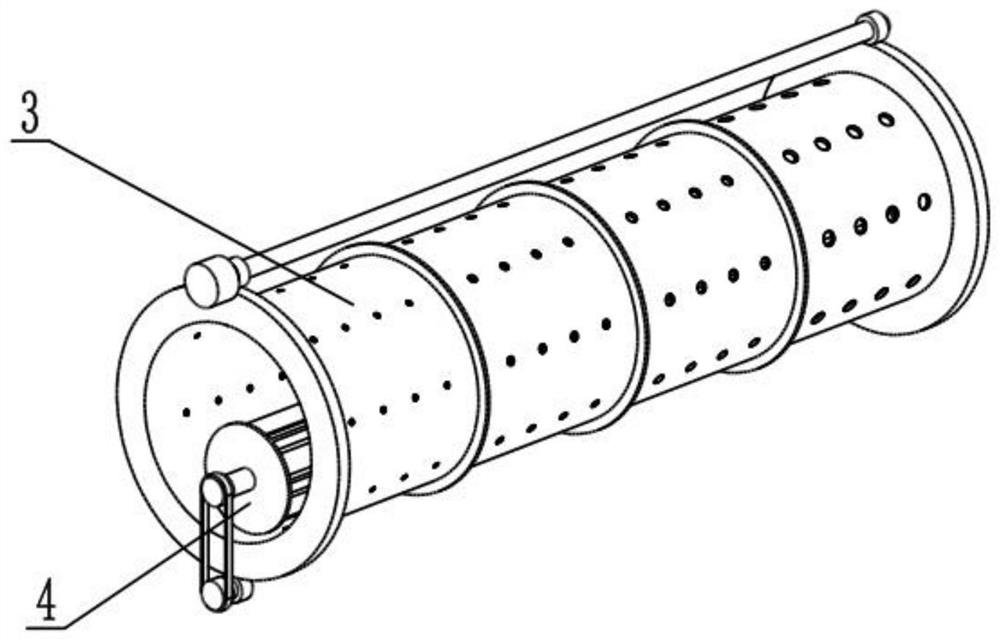

[0035] like Figure 1-11 As shown, a tea sorting system includes a base frame 1, a swing frame 2, a sorting screen 3, a stirring mechanism 4, a container 5, a baffle mechanism 6, a support limit mechanism 7 and an auxiliary support mechanism 8, and its characteristics That is: the middle part of the lower end of the swing frame 2 is rotatably connected to the middle part of the bottom frame 1, the sorting screen 3 is rotatably connected in the swing frame 2, and the stirring mechanism 4 is rotatably connected in the swing frame 2 and is located at In the sorting screen 3, the sorting screen 3 and the stirring mechanism 4 are connected by transmission, and there are multiple storage boxes 5, and the multiple storage boxes 5 are all fixedly connected to the bottom frame 1 and are all slidably connected to the sorting screen 3 , the baffle mechanism 6 is provided with a plurality, and the plurality of baffle mechanisms 6 are respectively slidably connected to the front ends of a ...

specific Embodiment approach 2

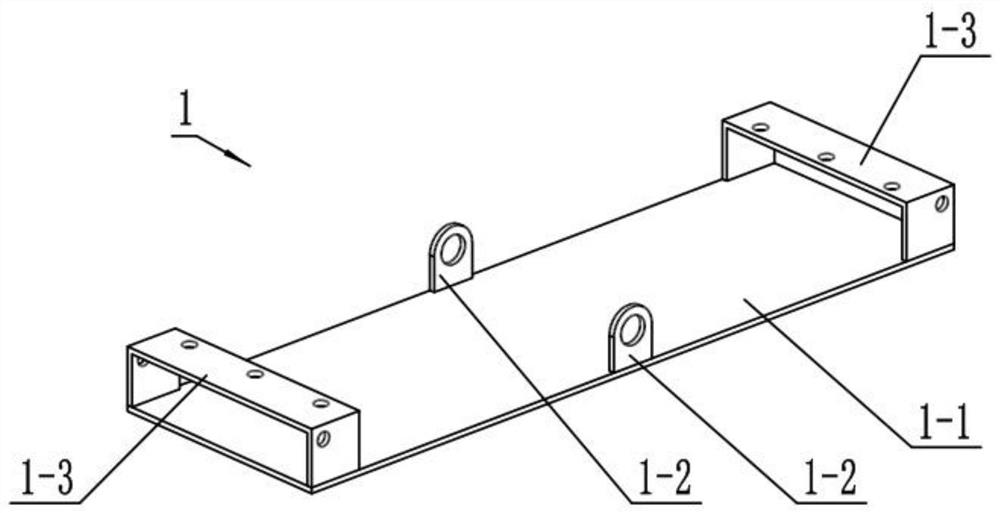

[0038] like Figure 1-11 As shown, the underframe 1 includes a base plate 1-1, a support plate 1-2 and a mounting plate 1-3, the front and rear ends of the middle part of the base plate 1-1 are fixedly connected with the support plate 1-2, the mounting plate 1 -3 is provided with two, and the left and right ends of the bottom plate 1-1 are fixedly connected with the mounting plate 1-3.

specific Embodiment approach 3

[0040] like Figure 1-11 As shown, the swing frame 2 includes a swing base plate 2-1, a rotating support plate 2-2, a side plate 2-3, a feeding pipe 2-4, a fixed seat 2-5 and a blocking plate 2-6, and the swing base plate 2 The front and rear ends of the -1 middle part are all fixedly connected with rotating support plates 2-2, the left and right ends of the swing base plate 2-1 are all fixedly connected with side plates 2-3, and the inboards of the two side plates 2-3 are all fixedly connected with The fixed seat 2-5, the feed pipe 2-4 are fixedly connected to the outside of the side plate 2-3 located at the left end, the blocking plate 2-6 is fixedly connected to the outside of the side plate 2-3 located at the right end, and the two rotating support plates 2 -2 are respectively rotatably connected to the two support plates 1-2.

[0041] Feeding pipe 2-4 is used to add sorted tea into the screen tube 3-1, and blocking plate 2-6 is used to take out the tea branches and other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com