Tooth pitch accumulative error compensation method for forming gear milling machining

A technology of accumulating errors and compensation methods, applied in the direction of gear teeth, components with teeth, belts/chains/gears, etc., can solve problems such as affecting production efficiency, affecting workpiece quality, and many parameters, and reducing calculation steps and parameters. The effect of improving the quantity and regulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The method provided by the invention obtains the compensated tooth pitch error by virtually calculating the compensated eccentricity error, and if the compensated tooth pitch cumulative error does not meet the accuracy requirement, iterative compensation is performed according to this method until the accuracy requirement is met.

[0047] The present invention will be further described below in conjunction with accompanying drawing and embodiment example:

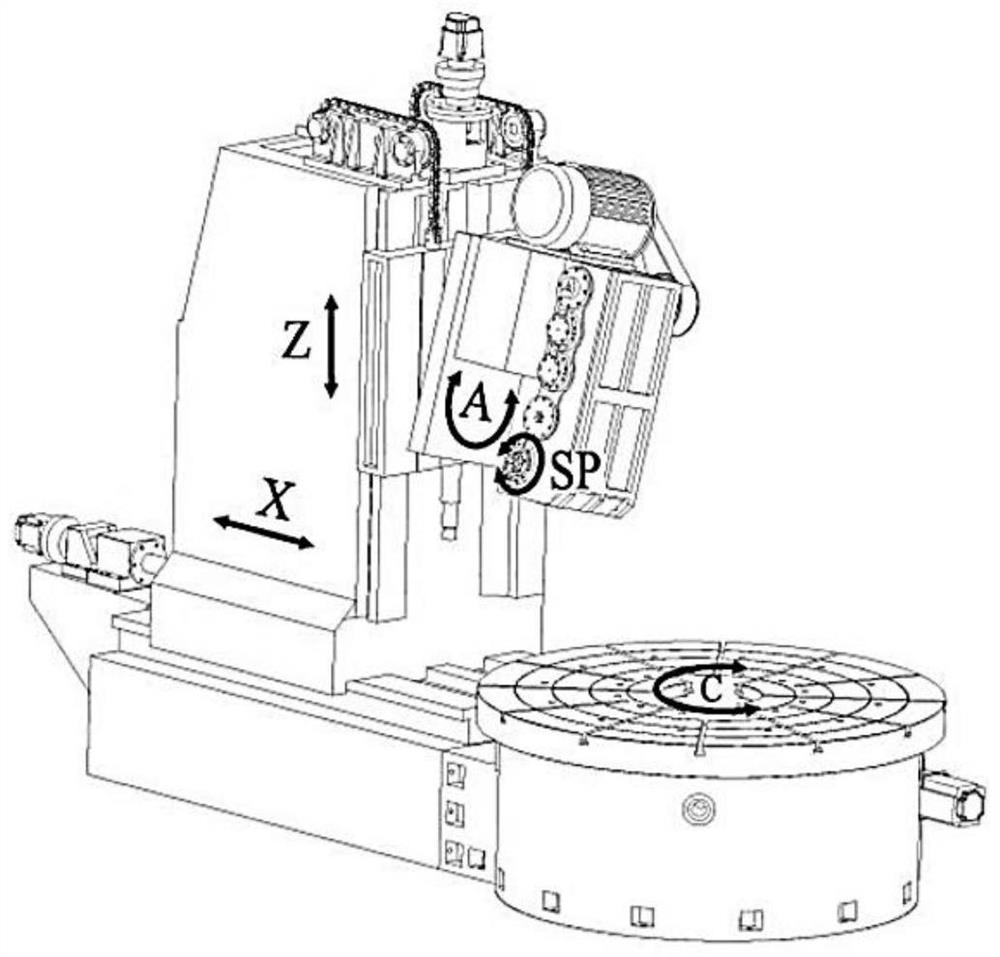

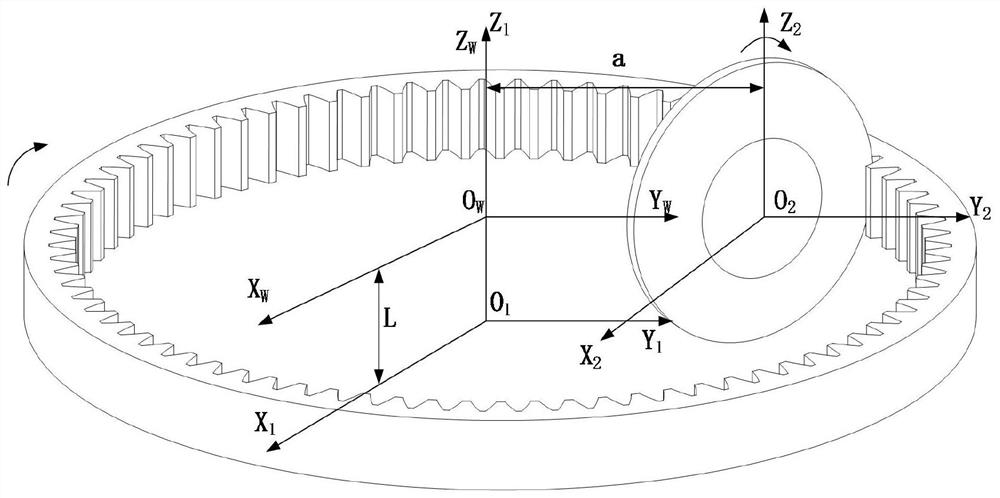

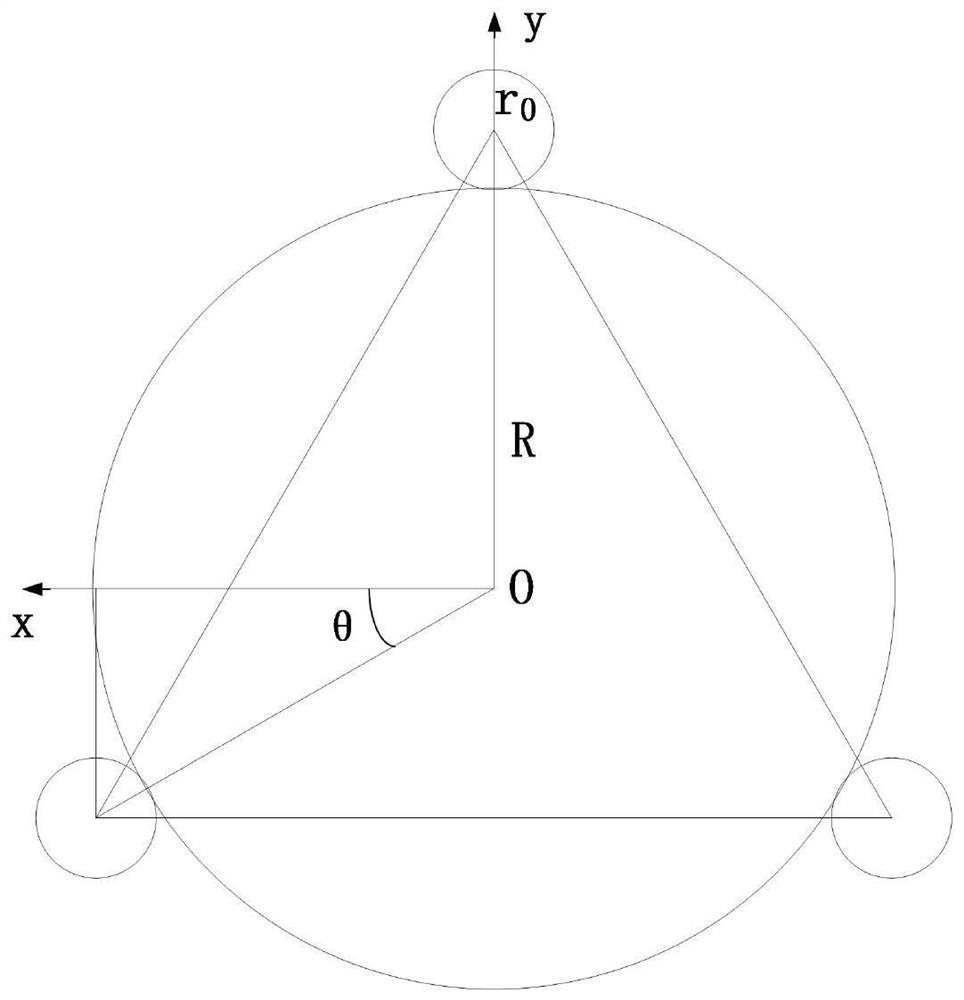

[0048] Such as figure 1 As shown, according to the working principle of gear milling by forming method, the motion axes of CNC gear milling machine include: the rotary motion of the gear blank (defined as the C axis) to realize the indexing of milling different gears; the milling cutter and the gear blank along the tooth The relative feed movement in the radial direction of the blank (defined as the x-axis) to complete the milling of the tooth groove; the movement of the milling cutter along the axial direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com