Full-automatic rotary no-dry sticker labeling machine

A rotary, fully automatic technology, applied in the direction of labeling machines, labels, winding strips, etc., can solve the problems of label detachment and inability to attach labels to objects to be affixed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

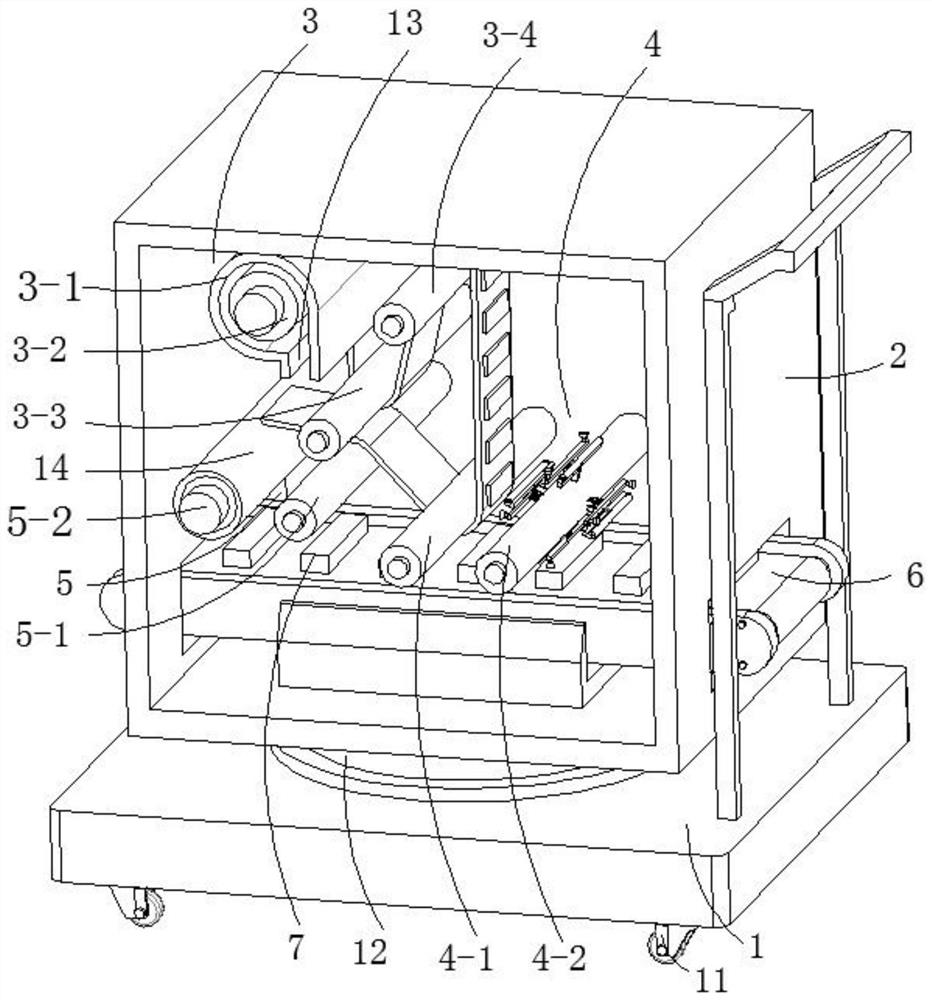

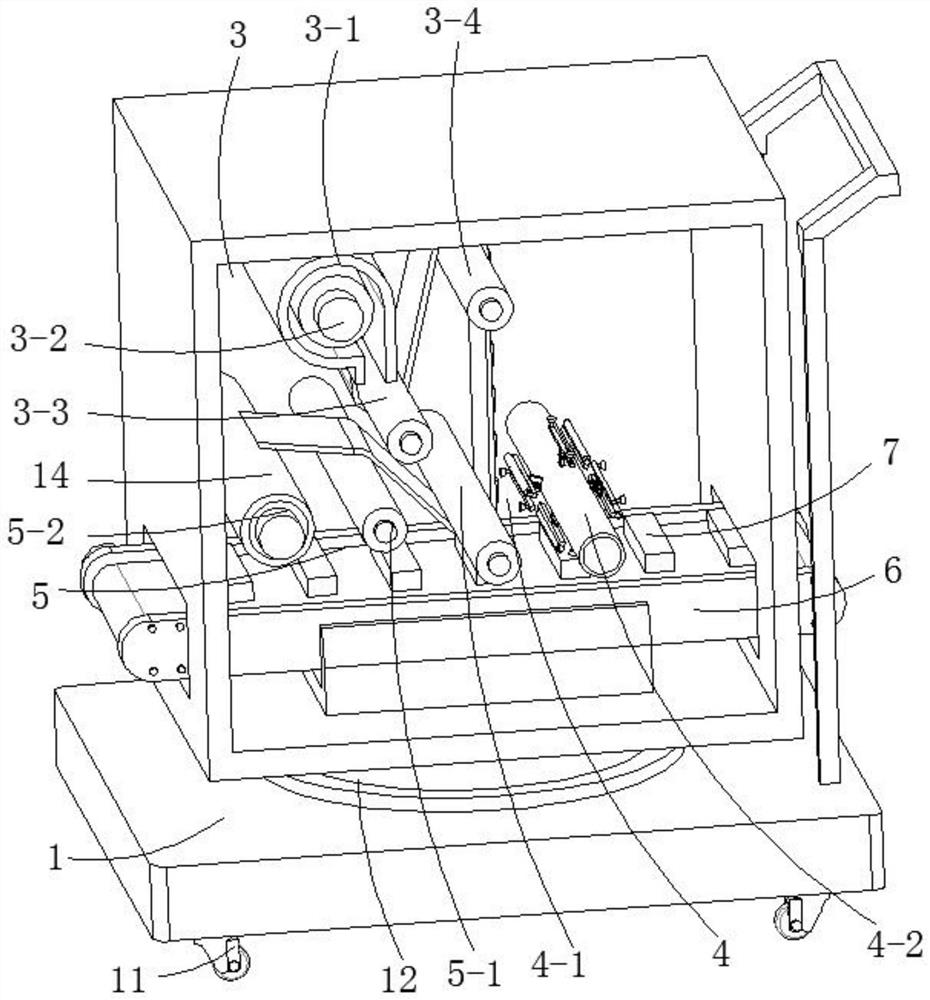

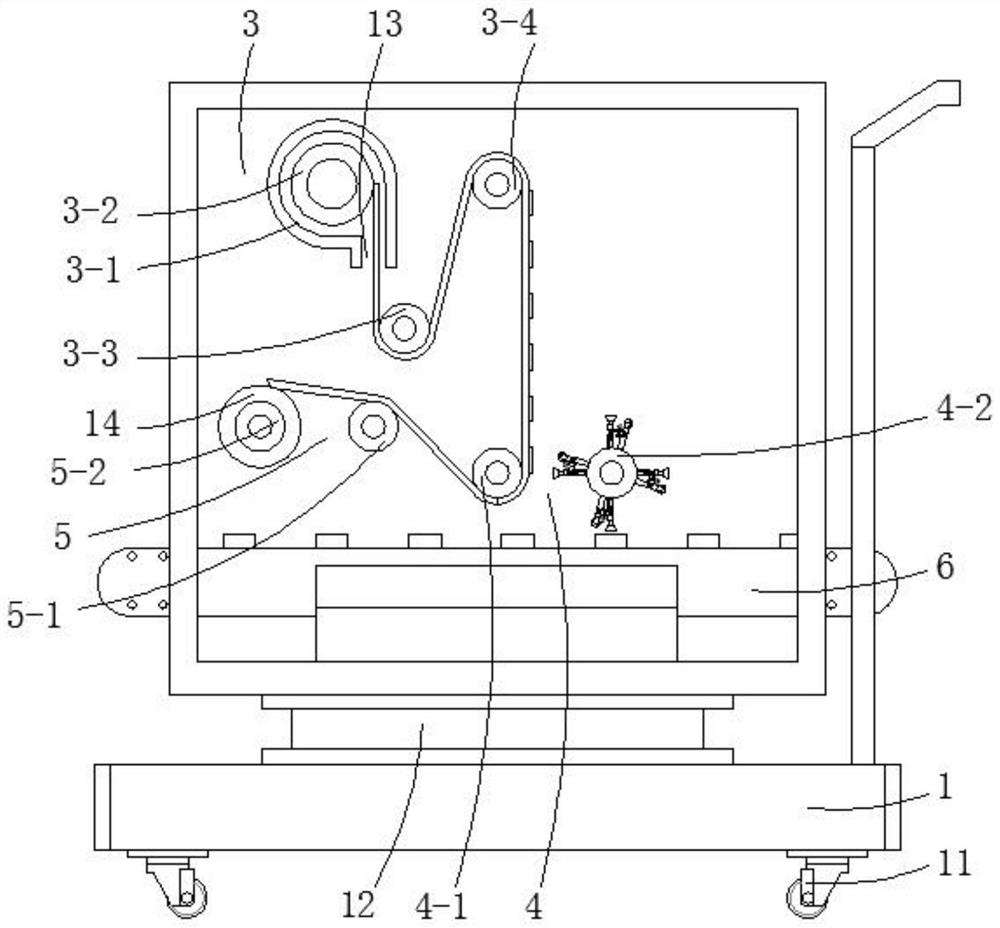

[0037] refer to Figure 1-5, a fully automatic rotary self-adhesive labeling machine, including a base 1, a labeling box 2, the labeling box 2 is rotated and set on the top of the base 1, and the inner wall of the top of the labeling box 2 is provided with a paper feeding roller group 3, and the feeding The output end of the paper roller group 3 is provided with a label paper separation assembly 4, and the output end of the label paper separation assembly 4 is provided with a recovery roller assembly 5, and the bottom wall of the labeling box 2 is also provided with a conveying assembly 6, on which the conveying assembly 6 There is a labeling object 7 for labeling, and the inner wall of the labeling box 2 is provided with a sensor for detecting the label; the label paper separation assembly 4 includes a transfer roller shaft 4-1, an adsorption roller shaft 4-2, and a transfer roller shaft 4 -1 and the adsorption roller shaft 4-2 are both rotated and arranged on the inner wall ...

Embodiment 2

[0043] refer to Figure 6-10 , is basically the same as in Example 1, and furthermore, the recovery roller group 5 includes the third discharge roller 5-1, the recovery roller 5-2, the third discharge roller 5-1 and the recovery roller 5 -2 rotation is set on the inner wall of the labeling box 2, and the recovery roller 5-2 is covered with a recovery cylinder 14; the adhesive paper output by the second delivery roller 3-4 is transported by the third delivery roller 5-1 On the recovery roller shaft 5-2, the recovery roller shaft 5-2 winds the used adhesive paper when rotating, so as to achieve the purpose of recycling.

[0044] Conveyor assembly 6 specifically adopts a conveyor belt, and adsorption assembly 8 includes a first fixed rod 8-1, an extension rod 8-2, and a suction cup 8-3, and the first fixed rod 8-1 is fixed on the side wall of the adsorption roller shaft 4-2 , the extension rod 8-2 is telescopically arranged on the first fixed rod 8-1, the suction cup 8-3 is fixe...

Embodiment 3

[0048] It is basically the same as the embodiment 2, furthermore, a sensor can be arranged on the inner wall of the labeling box 2, and the sensor is placed on the right side of the vertically pasted paper for detecting the label.

[0049] Working principle: when in use, the adhesive paper cylinder with the label attached is set on the winding roller shaft 3-2 of the paper feeding roller shaft group 3, and the adhesive paper on the adhesive paper cylinder passes through the first discharge roller shaft 3-3 in turn. , The second delivery roller shaft 3-4 is transported to the label paper separation assembly 4, specifically, the adhesive paper is placed on the transfer roller shaft 4-1 and transported to the direction of the recovery roller shaft group 5;

[0050] When the adhesive paper is placed between the transfer roller shaft 4-1 and the adsorption roller shaft 4-2, the adsorption component 8 on the adsorption roller shaft 4-2 adsorbs the label on the adhesive paper, specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com