Anti-falling lifting device

A lifting device and anti-fall technology, which is applied in the direction of lifting device, lifting frame, spring/shock absorber, etc., can solve problems such as safety accidents and falling objects, and achieve the effect of reducing safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

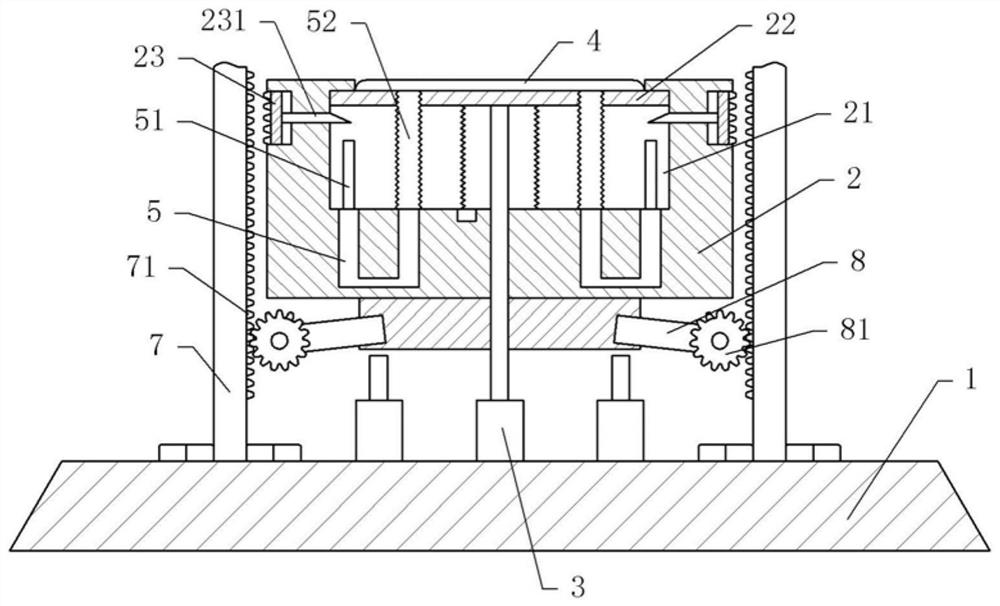

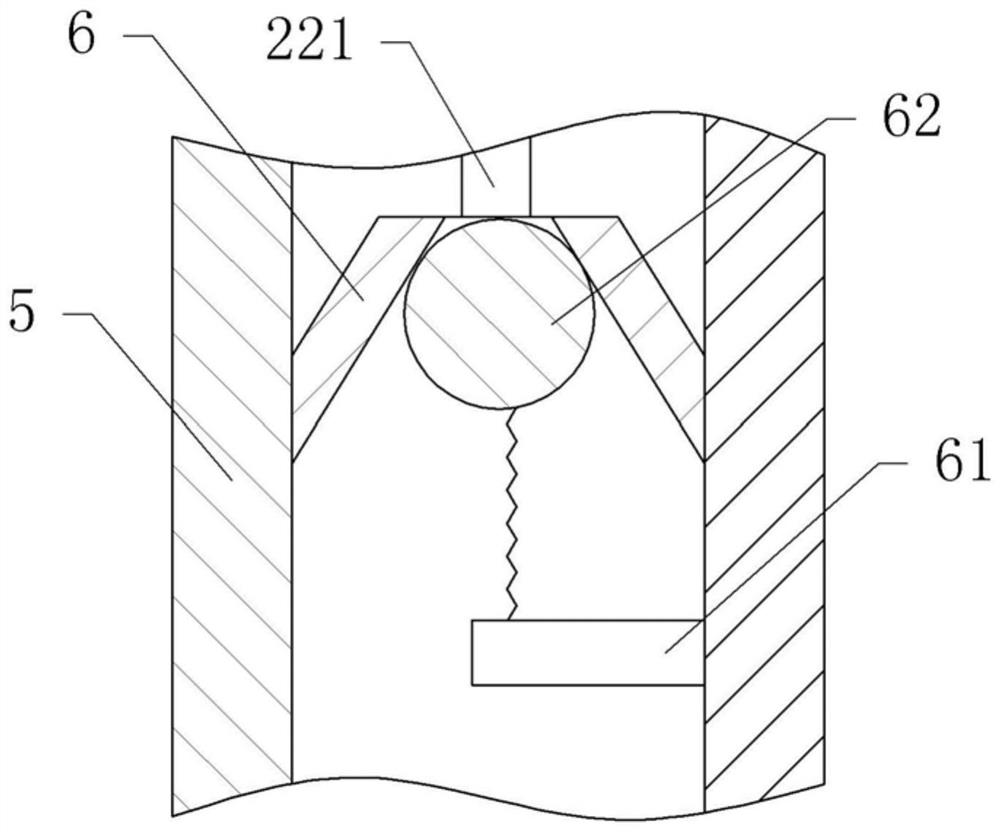

[0037] An anti-fall lifting device, basically as attached figure 1As shown, it includes a base 1, a power structure and a support platform 2 arranged in sequence from bottom to top, and the outer periphery of the support platform 2 is provided with a guardrail; the power mechanism is a pneumatic cylinder 3 fixed on the base 1. The top surface of the support platform 2 is provided with a groove 21 , and the support platform 2 is also provided with two slide grooves respectively communicating with the left and right sides of the groove 21 . The groove 21 is provided with a support plate 22, and both sides of the support plate 22 are fixed with sliders that cooperate with the chute, so that the support plate 22 can slide vertically along the groove 21; A spring is arranged between them, and the two ends of the spring are respectively welded to the bottom of the support plate 22 and the bottom of the groove 21. In this embodiment, the spring here uses a compression spring, and the...

Embodiment 2

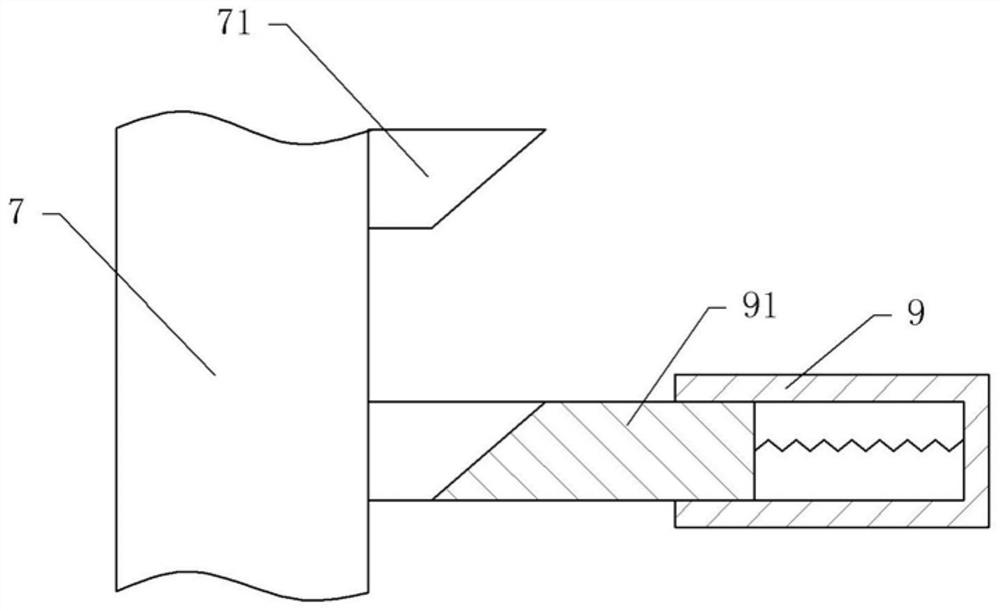

[0051] Embodiment 2 differs from Embodiment 1 only in that, as image 3 As shown, in this embodiment, the anti-slip component includes a sleeve 9 fixed on the end of the support rod 8 away from the mounting block, the sleeve 9 is arranged horizontally, and the end of the sleeve 9 is open towards the vertical rod 7, and the inside of the sleeve 9 is horizontal. A block 91 is slidably connected, and one end of the block 91 located in the sleeve 9 is welded with a spring, and the other end of the spring is welded on the fixed end surface of the sleeve 9 and the support rod 8 . The free end of block 91 is positioned outside sleeve 9, and the free end face of block 91 is inclined downward from top to bottom toward the direction close to vertical bar 7; The direction near the support platform 2 is inclined upward.

[0052] The specific implementation process is as follows:

[0053] When the support platform 2 moves up under the action of the power mechanism, the inclined surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com