Glass bottle annealing walking device

A walking device and glass bottle technology, which is applied in glass manufacturing equipment, glass transportation equipment, manufacturing tools, etc., can solve the problems that cannot meet the needs of glass bottle annealing treatment, affect the efficiency of glass bottle annealing processing, etc., and avoid glass bottle Damage, high degree of automation, and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

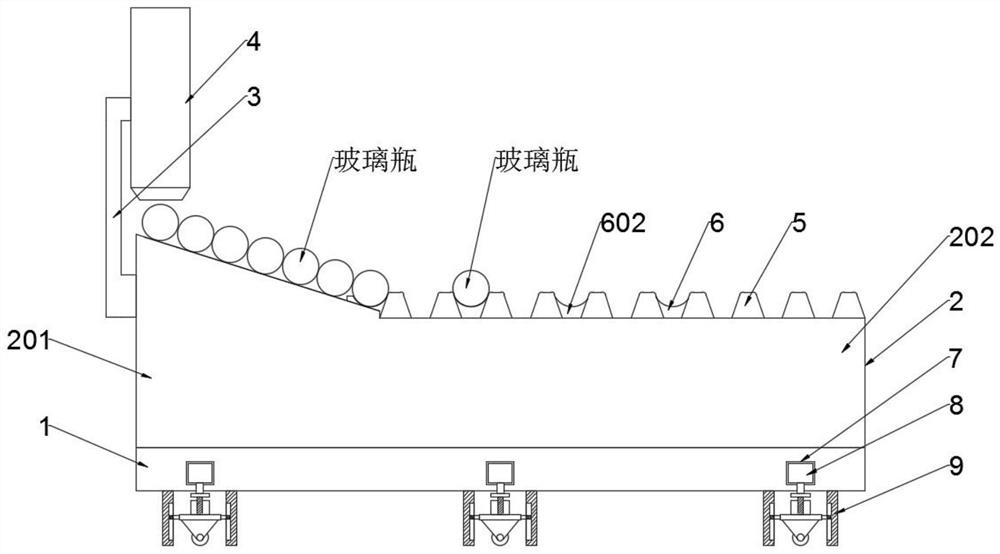

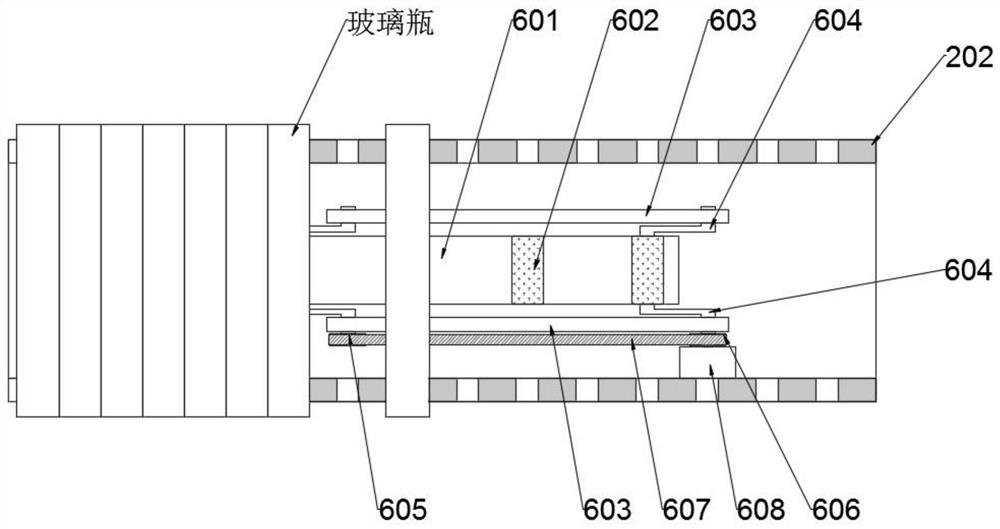

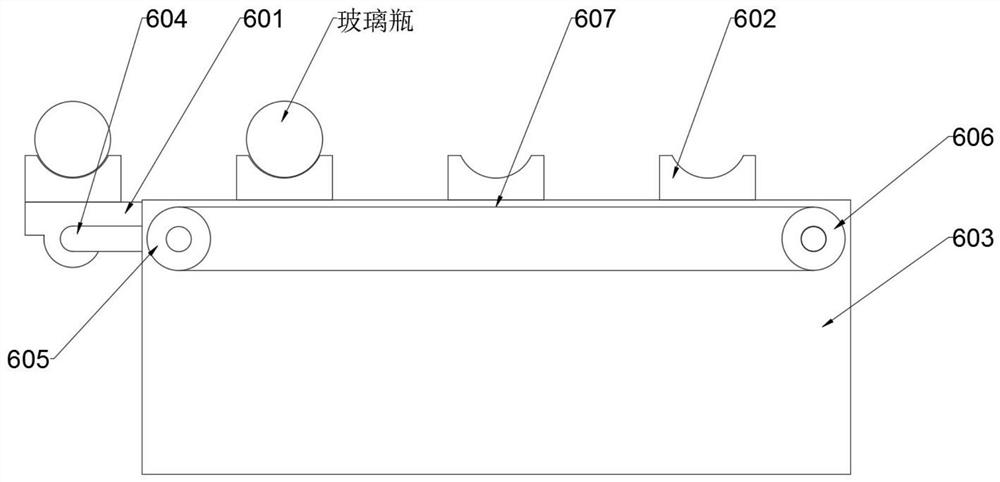

[0037] see Figure 1-2 , a glass bottle annealing walking device, comprising a base 1, the upper side of the base 1 is provided with a bracket 2, the bracket 2 includes a blanking frame 201 and a feeding frame 202 connected to each other, the glass bottles to be transported are arranged on the blanking frame 201, and the falling A connecting frame 3 is connected to the material rack 201, a bottle storage box 4 is fixed on the top of the connecting frame 3, a plurality of equally spaced blocking blocks 5 are fixed on the upper side wall of the feeding rack 202, and the upper surface of the base 1 is located between the brackets 2 A bottle feeding mechanism 6 is provided, and the bottle feeding mechanism 6 includes a conveying plate 601 arranged parallel to the support 2. The upper surface of the conveying plate 601 is fixed with a plurality of glass bottle support seats 602 distributed at equal intervals, and two adjacent glass bottle support seats The spacing of 602 is equal t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com