Building hoisting platform

A technology for hoisting platforms and buildings, which is applied in construction, building structure, processing of building materials, etc., can solve the problems of inconvenient adjustment, inability to adjust support rods, and insufficient bearing space of the mobile trolley structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

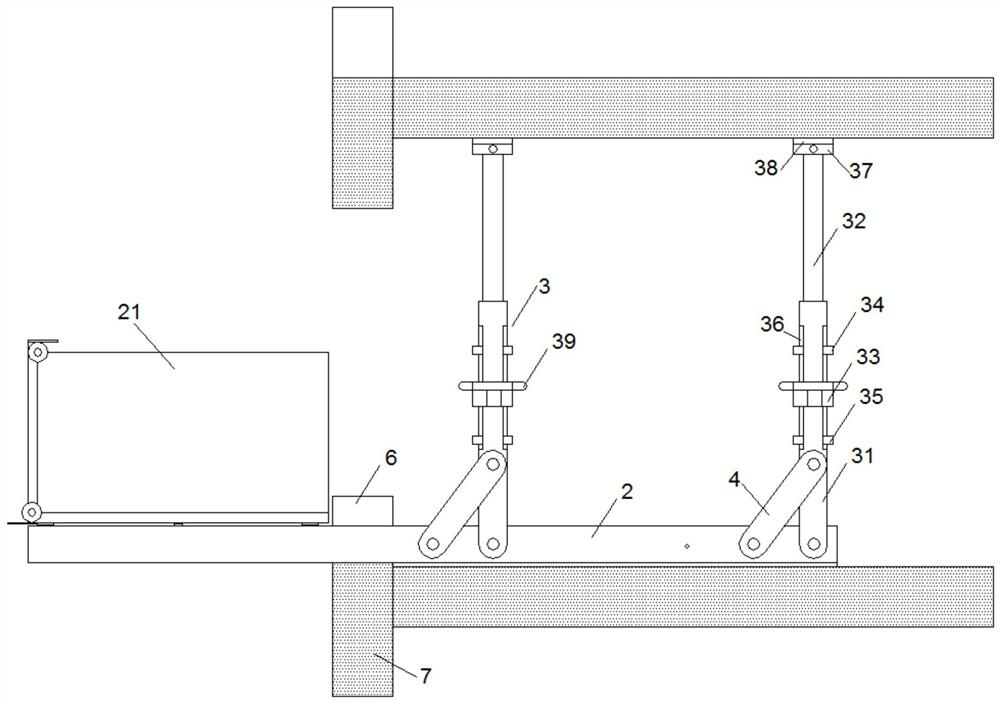

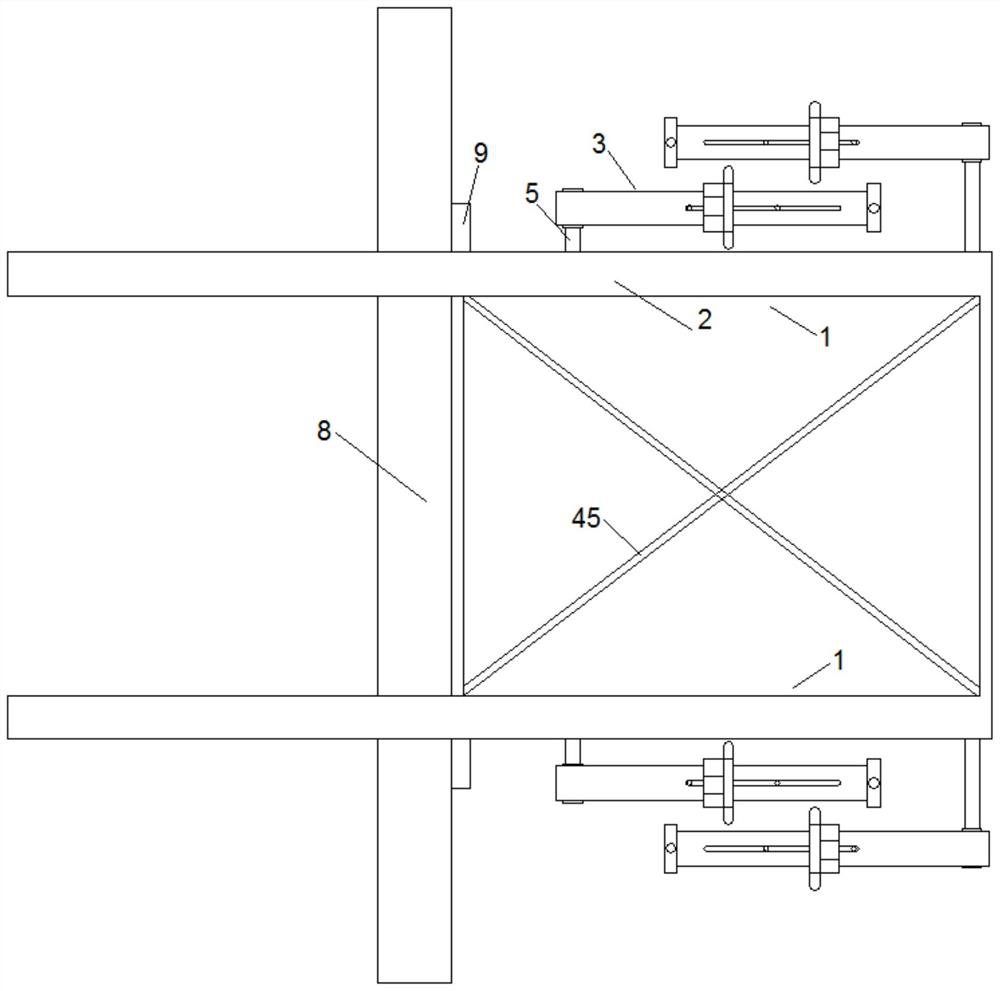

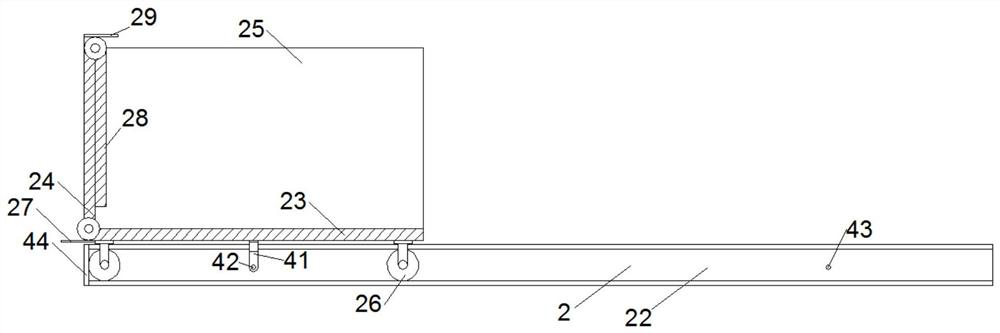

[0025] See attached Figure 1~5 . A construction hoisting platform, comprising two support assemblies 1 and a car body 21; the support assembly 1 includes a main beam 2, at least one telescopic rod 3 and an auxiliary rod 4 corresponding to the telescopic rod 3; the telescopic rod 3. The lower end is hinged to the rear section of the main beam 2, and the upper end of the telescopic rod 3 is supported on the lower surface of the upper floor, so that the rear section of the main beam 2 is pressed down on the upper surface of the lower floor; the front section of the main beam 2 extends to the outside; One end of the auxiliary rod 4 is detachably hinged on the telescopic rod 3, and the other end is detachably hinged on the main beam 2, so that the telescopic rod 3, the main beam 2 and the auxiliary rod 4 are surrounded by a triangle; A guide groove 22 is provided on the opposite inner side of the beam 2 ; the vehicle body 21 includes four bottom wheels 26 ; It can be seen from t...

Embodiment 2

[0027] See attached Figure 1~5 . A construction hoisting platform, comprising two support assemblies 1 and a car body 21; the support assembly 1 includes a main beam 2, at least one telescopic rod 3 and an auxiliary rod 4 corresponding to the telescopic rod 3; the telescopic rod 3. The lower end is hinged to the rear section of the main beam 2, and the upper end of the telescopic rod 3 is supported on the lower surface of the upper floor, so that the rear section of the main beam 2 is pressed down on the upper surface of the lower floor; the front section of the main beam 2 extends to the outside; One end of the auxiliary rod 4 is detachably hinged on the telescopic rod 3, and the other end is detachably hinged on the main beam 2, so that the telescopic rod 3, the main beam 2 and the auxiliary rod 4 are surrounded by a triangle; A guide groove 22 is provided on the opposite inner side of the beam 2 ; the vehicle body 21 includes four bottom wheels 26 ; It can be seen from t...

Embodiment 3

[0030] See attached Figure 1~5 . A construction hoisting platform, comprising two support assemblies 1 and a car body 21; the support assembly 1 includes a main beam 2, at least one telescopic rod 3 and an auxiliary rod 4 corresponding to the telescopic rod 3; the telescopic rod 3. The lower end is hinged to the rear section of the main beam 2, and the upper end of the telescopic rod 3 is supported on the lower surface of the upper floor, so that the rear section of the main beam 2 is pressed down on the upper surface of the lower floor; the front section of the main beam 2 extends to the outside; One end of the auxiliary rod 4 is detachably hinged on the telescopic rod 3, and the other end is detachably hinged on the main beam 2, so that the telescopic rod 3, the main beam 2 and the auxiliary rod 4 are surrounded by a triangle; A guide groove 22 is provided on the opposite inner side of the beam 2 ; the vehicle body 21 includes four bottom wheels 26 ; It can be seen from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com