Protection structure in steel structure building roof plate replacement project

A technology for protective structures and roof panels, applied in building construction, construction, building maintenance, etc., can solve problems such as inconvenience and unfavorable installation and handling of protective devices, and achieve the effects of convenient use, improved installation and handling work, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

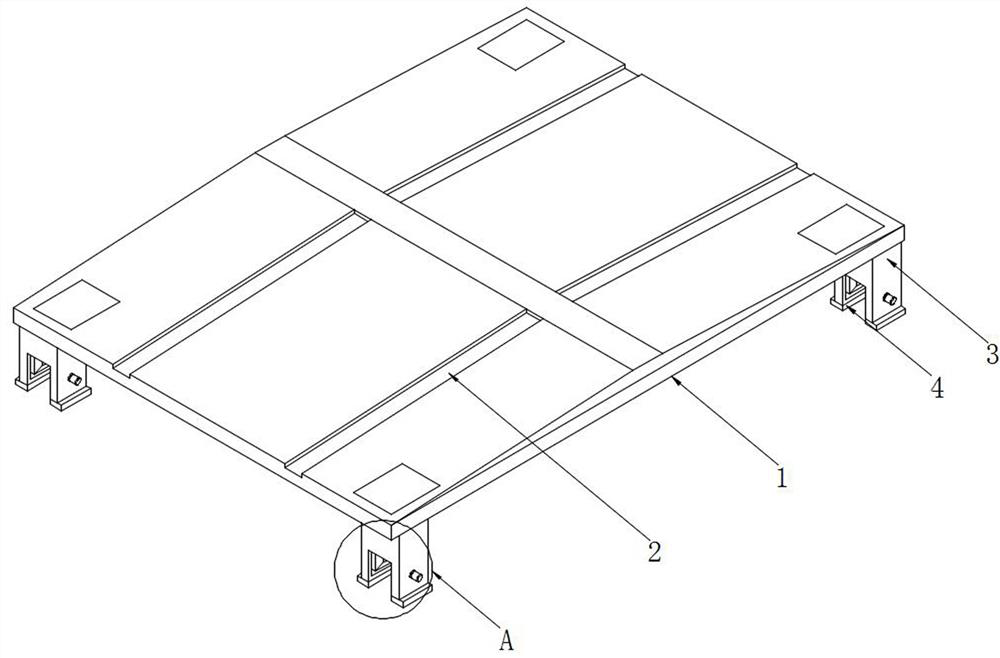

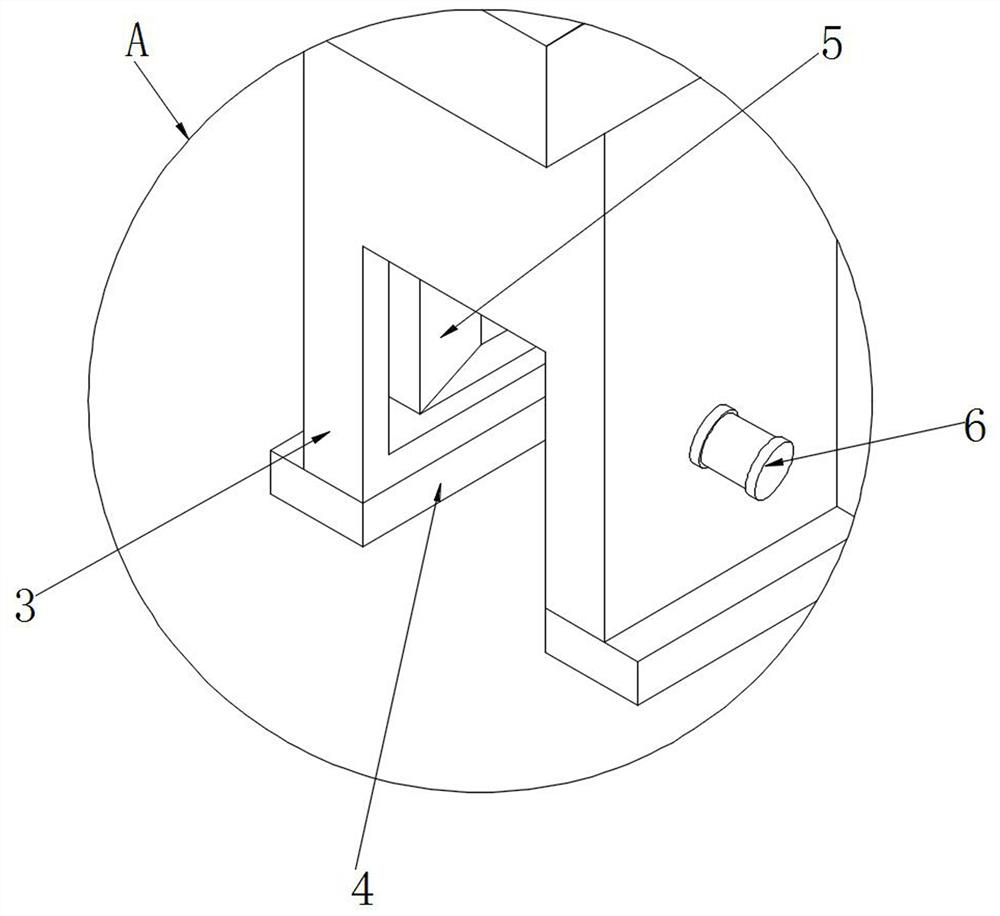

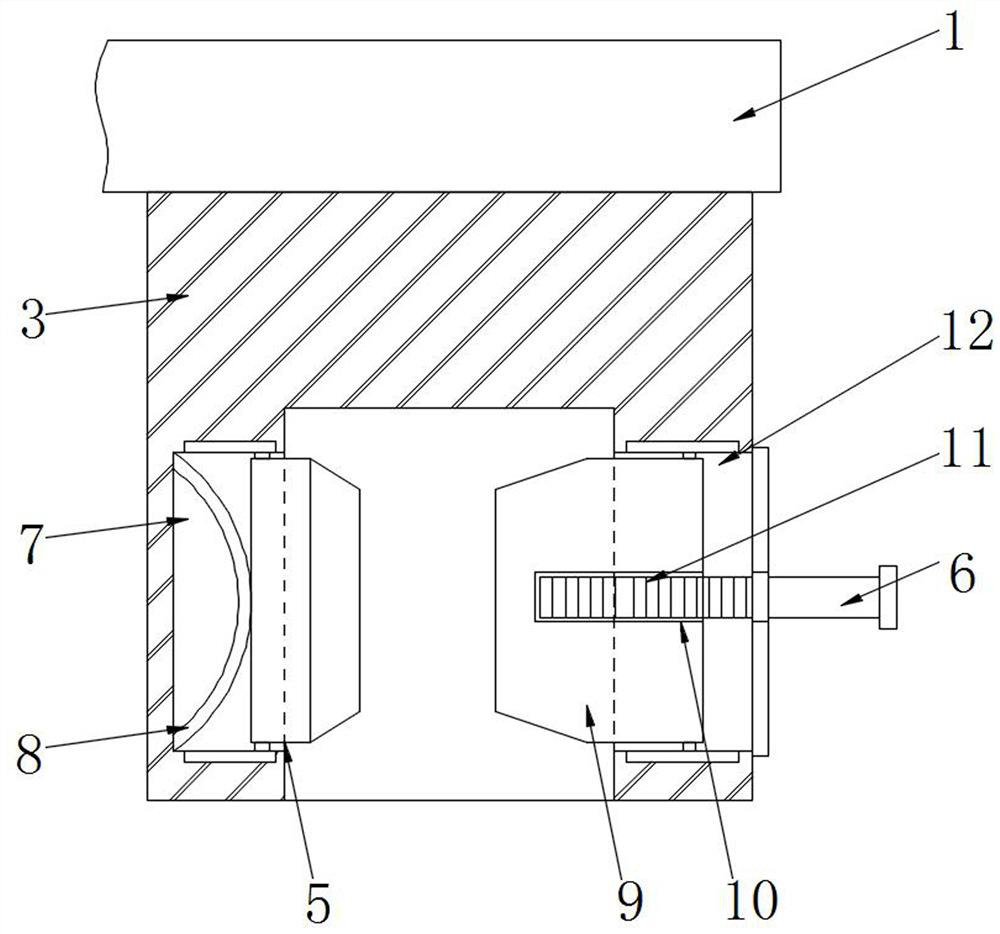

[0026] The main structure of this embodiment, such as Figure 1~3 As shown, by including the upper cover plate 1, side limit blocks 3 are fixedly installed at the four peripheral corners of the lower end of the upper cover plate 1, and several diversion grooves 2 are provided on both sides of the upper end surface of the upper cover plate 1. There is a lock groove 4 inside the limit block 3, and a first movable groove 7 is provided on one side of the inner wall of the lock groove 4, and a collision panel 5 is movably connected inside the first movable groove 7, and the connection between the collision panel 5 and the first movable groove 7 An elastic piece 8 is fixedly connected between them, and the other side of the inner wall of the lock groove 4 is provided with a second movable groove 12 .

[0027] The specific implementation method is that when the upper cover plate 1 is installed, the external personnel can align the side limit block 3 with the external rod body, and af...

Embodiment 2

[0029] In this embodiment, on the basis of the above embodiments, the structure of the second movable groove 12 is further limited, such as image 3 As shown, the inside of the second movable groove 12 is movably connected with a beveled cone plate 9 , and a rotating threaded rod 6 is rotatably connected between the beveled cone plate 9 and the edge limiting block 3 . Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

Embodiment 3

[0031] In this embodiment, on the basis of the foregoing embodiments, the structure of the inclined cone plate 9 is further limited, such as image 3 Therefore, the inside of the inclined cone plate 9 is provided with a built-in through groove 10 for the movement of the rotating threaded rod 6 , and the inner wall of the built-in through groove 10 is provided with a pattern corresponding to the external thread 11 . Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com