Elastic velvet band with double-sided fluff, processing technology and processing device

A processing device and elastic technology, applied in textile processing machine accessories, textile material processing, continuous processing of textile materials, etc., can solve problems such as affecting wear and inconvenient use, and achieve the effect of improving adaptability and avoiding wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Such as figure 1 Shown, a kind of elastic velvet belt of double-sided fine hair, this elastic velvet belt comprises the elastic velvet belt of double-sided fine hair and active dye solution, and the double-sided fine hair of elastic velvet belt, active dye solution is made up of the composition of following parts by weight : 25-33 parts of polypropylene, 1.2-1.4 parts of silver powder, 22-28 parts of polyaniline, 35-45 parts of polyurethane, 12-18 parts of foaming agent, 2.3-4.5 parts of alkyl phosphate and 4.5-6 parts of penetrating agent share.

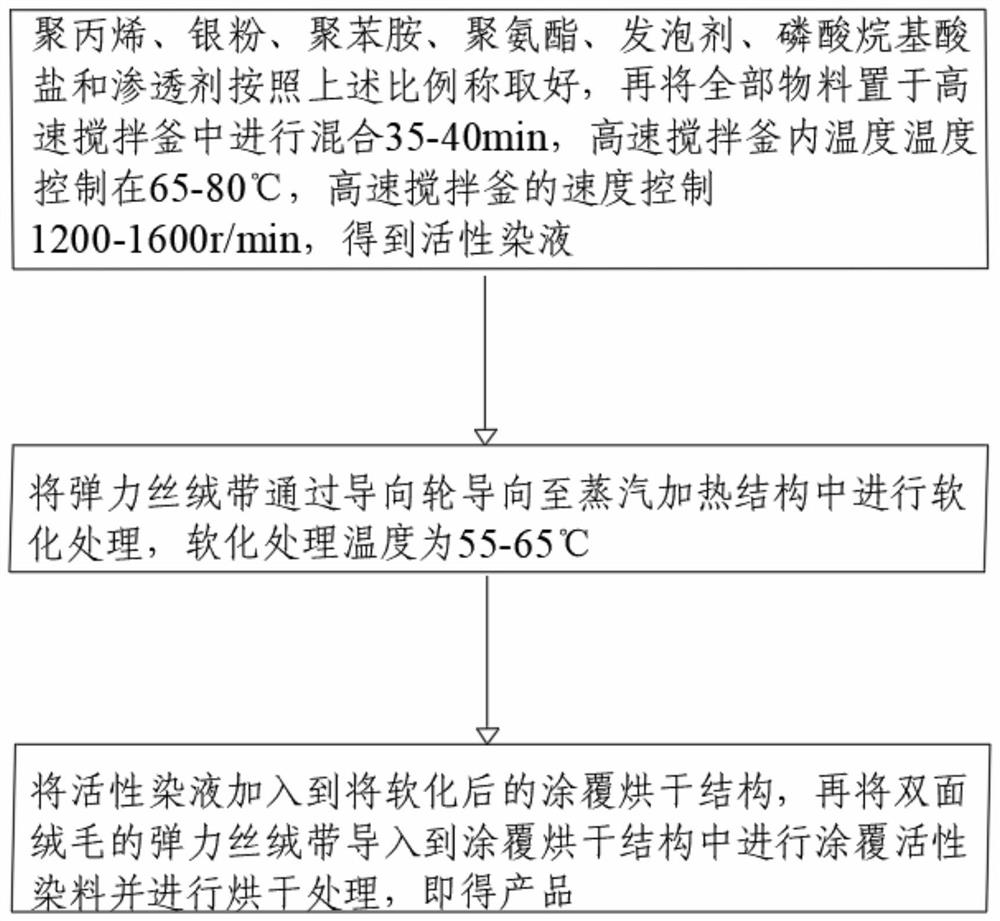

[0045] A kind of processing technology of the elastic velvet belt of double-sided fluff, the processing technology step is as follows:

[0046] Step 1. Weigh polypropylene, silver powder, polyaniline, polyurethane, foaming agent, alkyl phosphate and penetrating agent according to the above ratio, and then put all the materials in a high-speed stirring tank for 35-40 minutes, and stir at a high speed The temperature in the k...

Embodiment 2

[0051] Embodiment 2 is a further improvement to Embodiment 1.

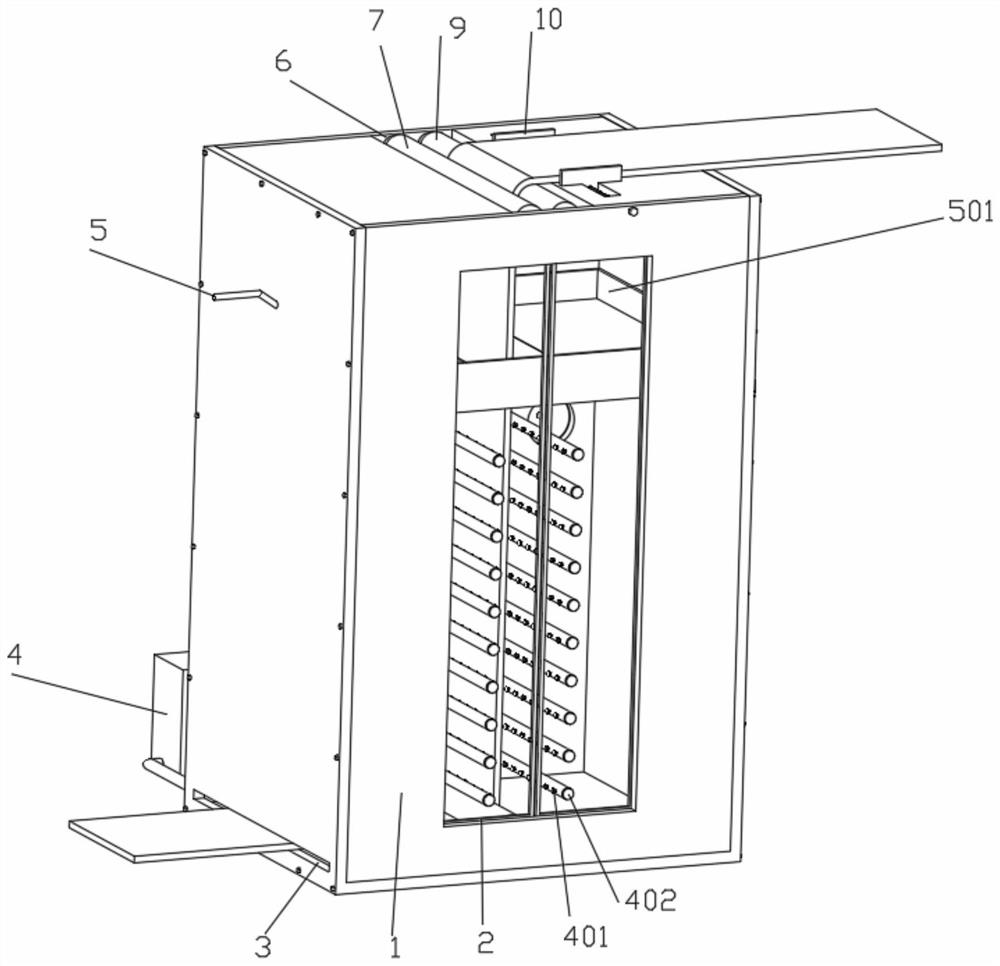

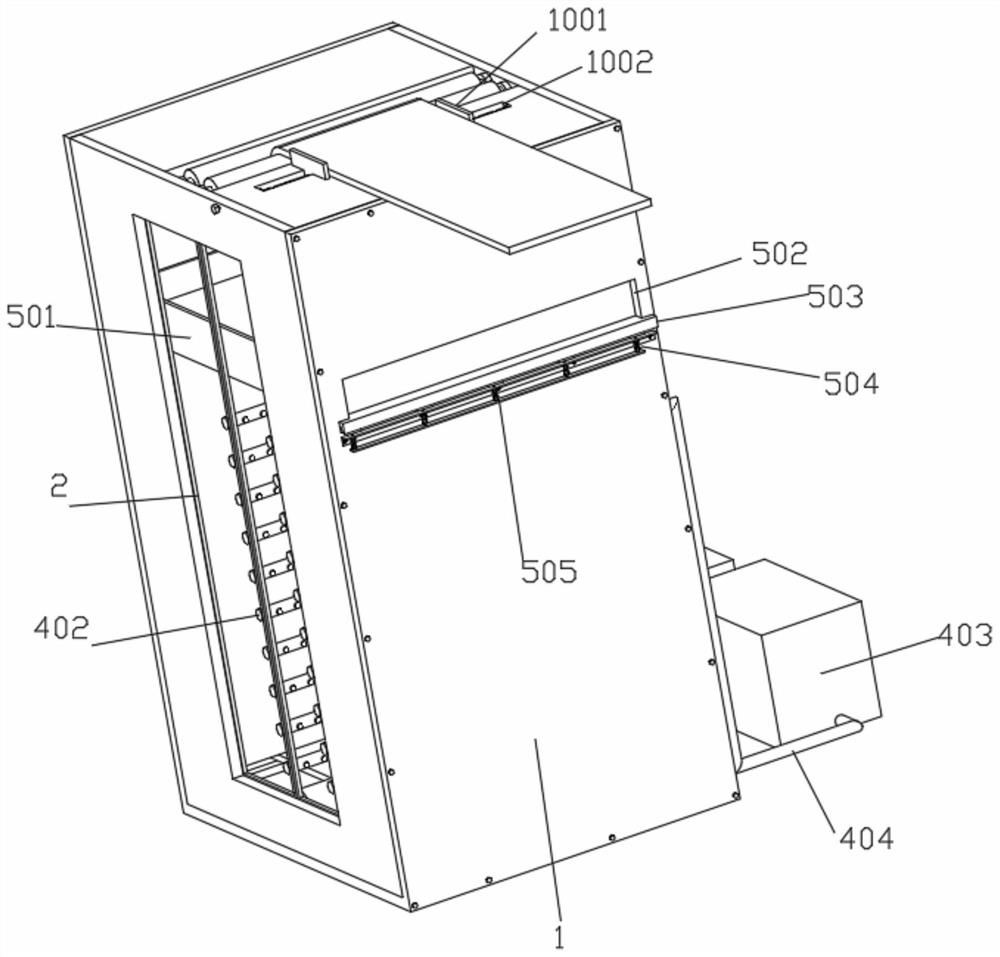

[0052] Such as figure 2 , 3 , 4, 5, 6, 7, 9, 10, and 11 show a processing device for an elastic velvet tape with double-sided fluff, the processing device is a coating and drying structure in step 3, including a box body 1 and a box body 1 It is connected with a guide structure for guiding the elastic velvet belt. The guide structure includes a discharge hole 3, a feed hole 6, a first guide roller 7, a second guide roller 8 and a third guide roller 9. The feed hole 6 is set in the box body 1, the inner wall of the feeding hole 6 is respectively rotatably connected with the first guide roller 7 and the third guide roller 9 through symmetrically fixedly connected bearings, and the elastic velvet belt is between the first guide roller 7 and the third guide roller 9 Movable, the lower end of the inner wall of the box body 1 is rotatably connected with a second guide roller 8 through a fixedly connected bearing, the...

Embodiment 3

[0058] Embodiment 3 is a further improvement to Embodiment 1.

[0059] Such as Figure 4 , 5 , 7, and 8, the box body 1 is provided with a drying structure 4 for drying the elastic velvet belt between the material box 501 and the second guide roller 8, and the drying structure 4 includes a nozzle 401, a horizontal pipe 402, a drying box 403, air inlet pipe 404, intermediate pipe 405, electric heater 406 and outlet pipe 407, the output end of electric heater 406 is fixedly connected with outlet pipe 407, and the upright position of outlet pipe 407 is evenly fixedly connected with horizontal pipe 402, and the inner wall of horizontal pipe 402 The nozzle 401 for spraying air is uniformly and fixedly connected, and the nozzle 401 is arranged on both sides of the elastic velvet belt, the input end of the intermediate pipe 405 is fixedly connected with a drying box 403, and the drying box 403 is connected with an air inlet pipe 404, which is fixedly installed in the box In the mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com