Sliding plug door assembly

An assembly and door panel technology, applied in the field of drive mechanism, can solve the problems of poor door sealing, no good solution, damaged acceleration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

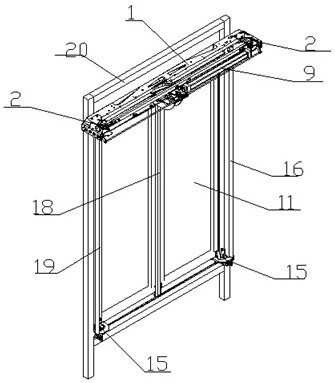

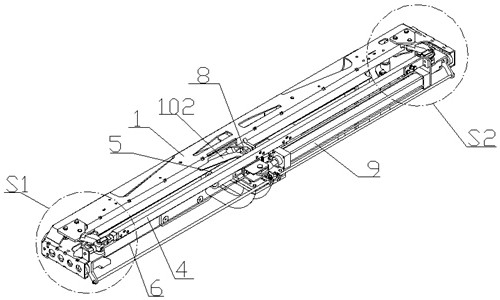

[0073] This embodiment provides a double sliding door assembly, such as Figures 1 to 11 , 17 to 23, mainly by the base 1 fixed on the door frame 20, two sets of shaft-connected drive mechanisms 2, sliding rod 3, pull rod 4, two sliding sleeves 5, wire drawing 6, two wire drawing wheels 7, Guide wheel 8, power source, two door frames 10 and two door panels 11 form.

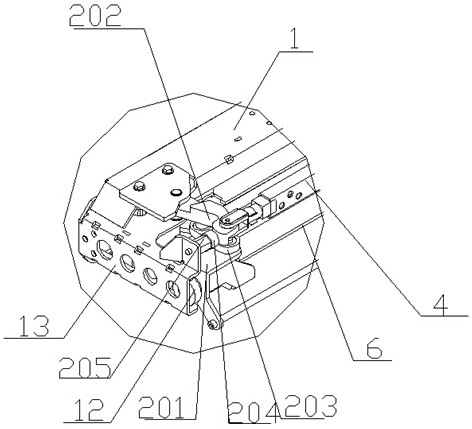

[0074] Two sets of shaft-connecting drive mechanisms 2 are respectively installed on both ends of the upper part of the base 1. The two sets of shaft-connecting drive mechanisms 2 are mainly composed of a sliding bracket 201, a driving arm 202 and a connecting arm 203. The sliding brackets in the two sets of coupling driving mechanisms 2 201 is fixedly connected through the slide bar 3, and the driving arm 202 is rotatably connected through the pull rod 4, and the slide bar 3 and the pull rod 4 are parallel to each other. In each group of shaft-connecting drive mechanisms 2, the sliding bracket 201 in one group i...

Embodiment approach 2

[0085]This embodiment provides a single sliding door assembly, which has roughly the same structure as the double sliding door assembly in Embodiment 1, and only needs to connect one sliding sleeve, wire drawing and two sliding sleeves in the double sliding door assembly. The first drawing wheel can be removed, and the rest of the structure and working principle are exactly the same, so I won’t repeat them here.

Embodiment approach 3

[0087] This embodiment is a further improvement of Embodiment 1. The main improvement is that in the plug door assembly in Embodiment 1, only the top ends of the door panels 11 on both sides enter the guide groove 102 through the guide wheel 8 for positioning, and the bottom of the door panels 11 There is no positioning mechanism at the end, which will cause the bottom end of the door panel 11 to shake easily when the vehicle runs into a bumpy situation during driving. In this embodiment, a door panel positioning mechanism 15 for positioning the bottom ends of both side door panels 11 is added in the plug door assembly, effectively avoiding the situation that the bottom ends of both side door panels 11 shake and are not stable during driving.

[0088] Specifically, as Figures 12 to 16 , in the plug door assembly in this embodiment, two rotating arms 16 are respectively provided on both sides of the two door panels 11, and the upper and lower ends of the two rotating arms 16 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com