Drill rod centering guide for oil-gas drilling

A technology for oil and gas drilling and centralizers, which is applied in the direction of drill pipes, drilling equipment, drill pipes, etc. It can solve the problems of inducing downhole accidents and reducing the risk of stuck pipe in the mud bag of the centralizer, and achieve the effect of reducing the risk of stuck pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

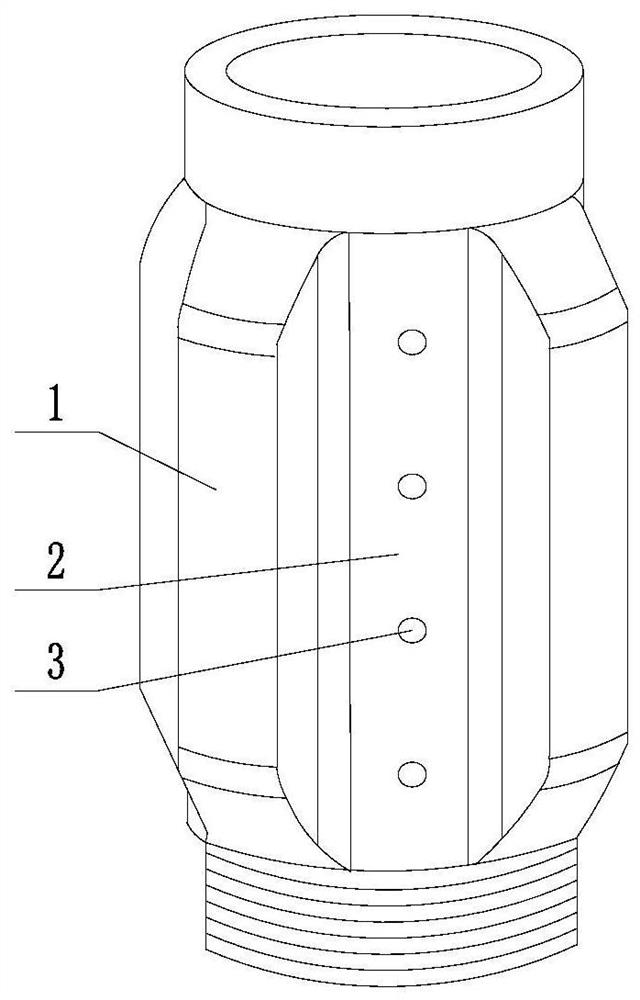

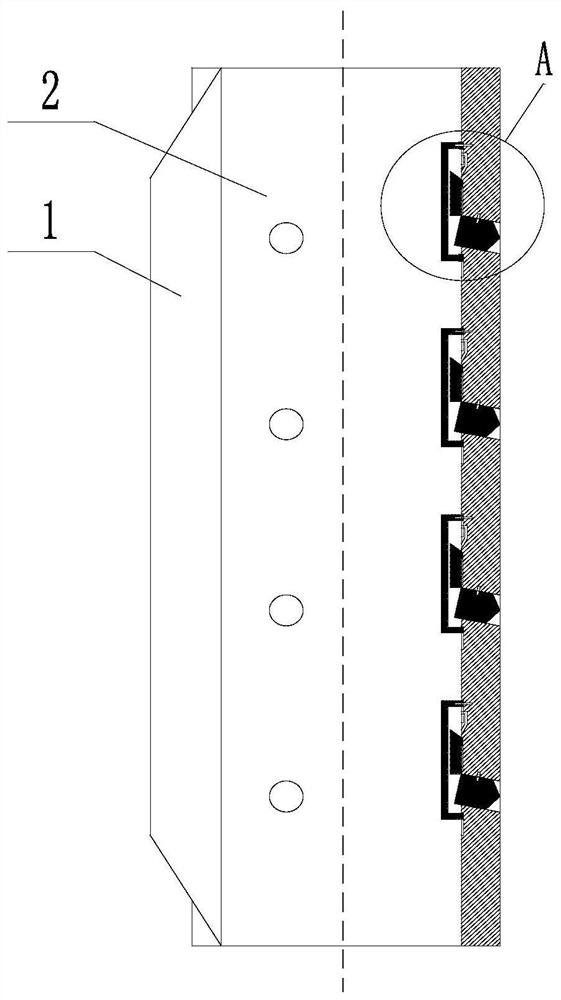

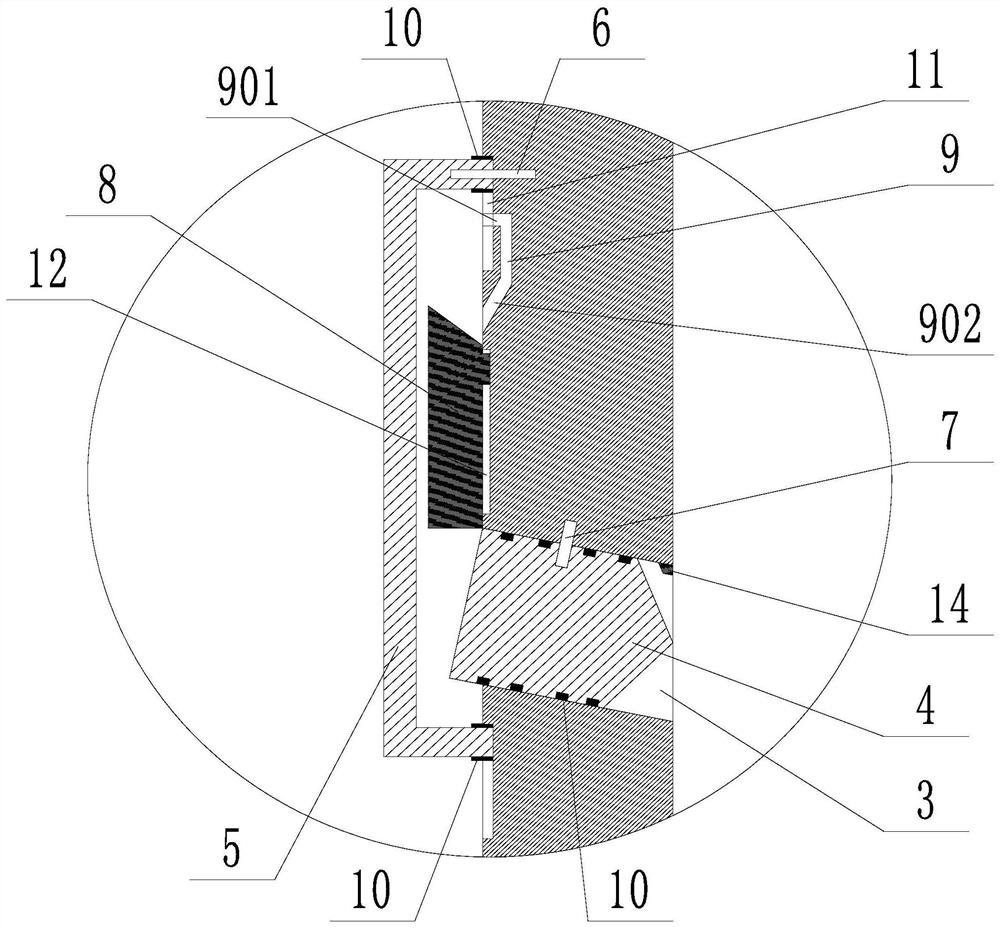

[0038] Such as Figure 1 to Figure 5 The drill pipe centralizer shown includes several centralizing wings 1 and an upper backflow channel 2 between two adjacent centralizing wings 1, and is characterized in that several through holes 3 are provided on the upper backflow channel 2, so that The through hole 3 is sealed with a tapered part 4, the tapered end of the tapered part 4 faces the outside of the through hole 3, and the tapered part 4 is connected with the wall of the through hole 3 through the first shear pin 7; It includes a sliding sleeve 5 corresponding to the through holes 3 one by one, the sliding sleeve 5 is sealed and connected to the inner wall of the centralizer, and the sliding sleeve 5 and the centralizer are connected by a second shear pin 6, and the first The shear stress of the shear pin 7 is less than the shear stress of the second shear pin 6; each sliding sleeve 5 is provided with a sliding push block 8 and a pressurized flow channel 9, and the inlet sec...

Embodiment 2

[0043] Such as Figure 1 to Figure 5 For the drill pipe centralizer shown, on the basis of Embodiment 1, the through hole 3 is inclined downward from the inside to the outside, the outer diameter of the conical part 4 is less than or equal to the inner diameter of the through hole 3, and the conical part 4 and the through hole 3. Several O-rings 10 are dynamically sealed between the hole walls. The bottom surface of the cone 4 is perpendicular to the axis of the through hole 3. When the first shear pin 7 is connected, the top end of the bottom surface of the cone 4 is flush with the inner wall of the centralizer, and the cone 4 supports the slide from below. Push block 8. The inner wall of the centralizer defines a first chute 11 for the sliding of the sliding sleeve 5 , and the sliding sleeve 5 and the first chute 11 are in dynamic and sealing cooperation. The inner wall of the centralizer defines a second sliding slot 12 for the sliding push block 8 to slide. The outlet s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com