Method for reducing water hammer effect, liquid flow shutoff system and water conservancy project

A technology of water hammer effect and liquid flow, applied in water conservancy projects, water conservancy engineering equipment, pipes/pipe joints/fittings, etc., can solve problems such as time delay, pipeline damage, large gate damage, etc., and achieve low cost, time saving, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

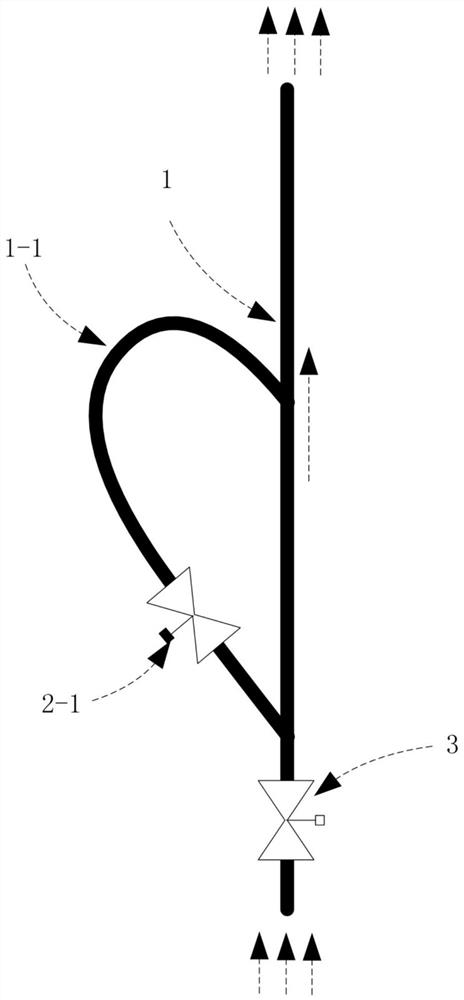

[0031] Embodiment 1, as figure 1 As shown, a method for reducing the water hammer effect is characterized in that when designing the fluid channel, the bypass channel (1-1) of the Tesla valve is integrated on both sides of the main channel (1), and the fluid direction of the fluid channel For the high-resistance direction of the Tesla valve structure; design the bypass valve (2-1) on the bypass channel (1-1), design the main valve (3) on the main channel (1); design the main channel (1-1) ) when working, the main valve (3) opens the bypass valve (2-1) and closes; when the main channel (1) needs to be shut off, first close the bypass valve (2-1), so that the main channel (1) and the bypass water channel (1-1) together constitute a Tesla valve, which reduces the flow rate of the fluid channel and then closes the main valve (3).

[0032] The bypass waterway (1-1) is a pipe or a tank.

[0033] Road (1) is a pipe or a groove.

[0034] The bypass valve (2-1) is a pipeline valve o...

Embodiment 2

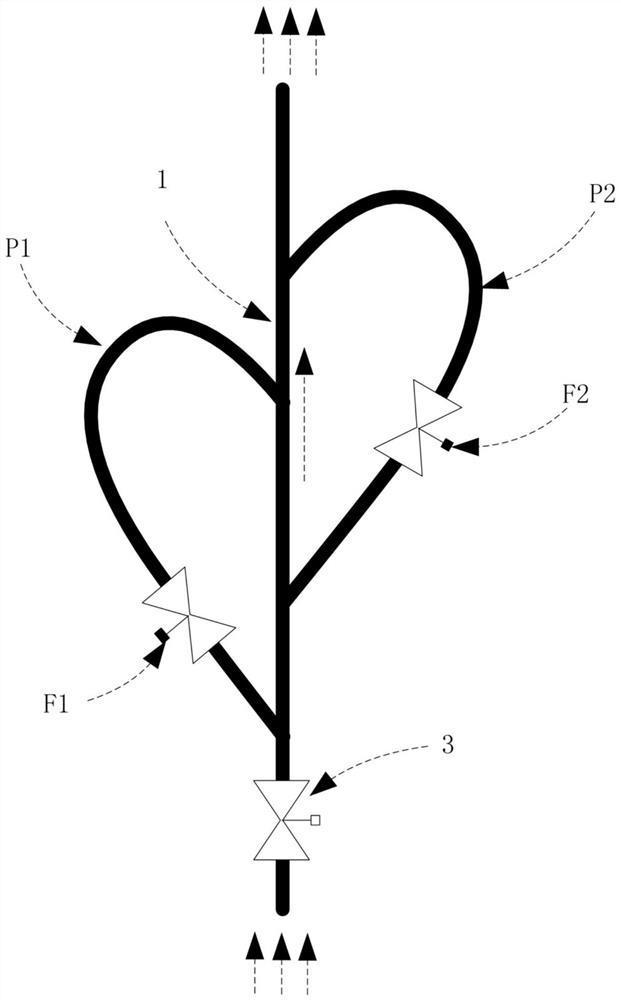

[0036] Embodiment 2, as Figure 2-5 As shown, the number of bypass channels (1-1) is 2, the first bypass valve (F1) is located in the fluid path of the first bypass channel (P1), and the second bypass valve (F2) is located in the second bypass channel (P2) on the fluid path.

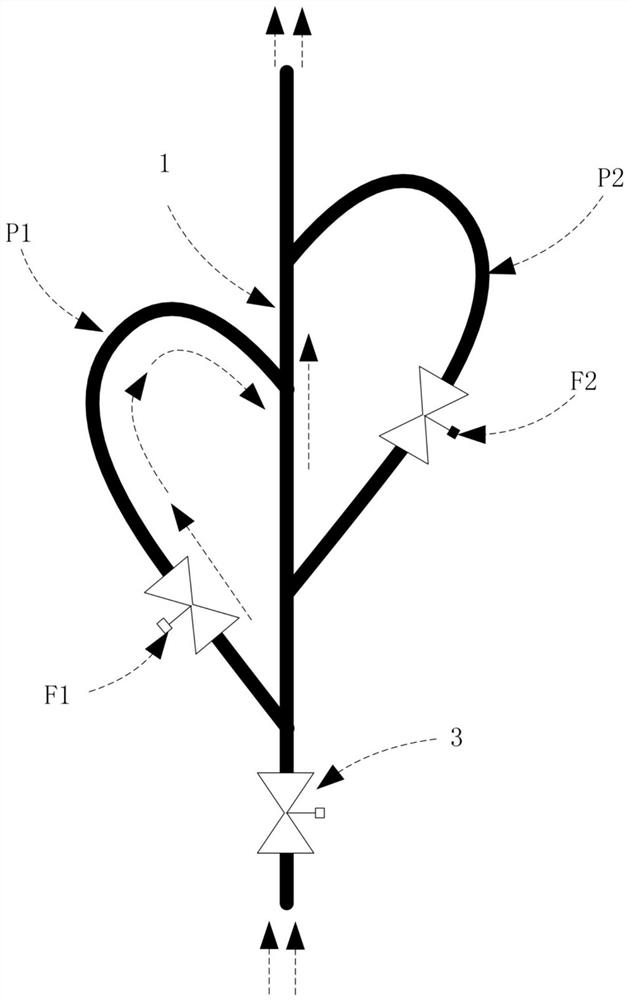

[0037] implementation, 3, such as Figure 6 The number of bypass waterways (1-1) shown is greater than two, and each bypass waterway (1-1) has a bypass valve (2-1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com