Ceramic capacitive pressure sensor and preparation method thereof

A pressure sensor, ceramic capacitor technology, applied in the fluid pressure measurement, instrument, measurement force and other directions using capacitance change, can solve the problems of low output reliability, undetectable, unable to guarantee filling of the cavity, etc., to achieve output reliability. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

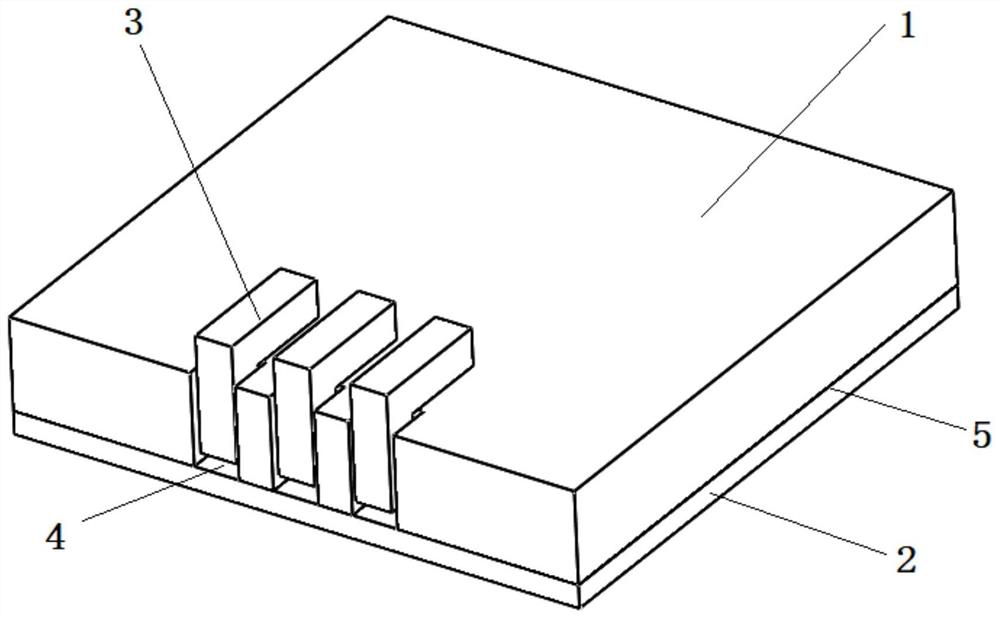

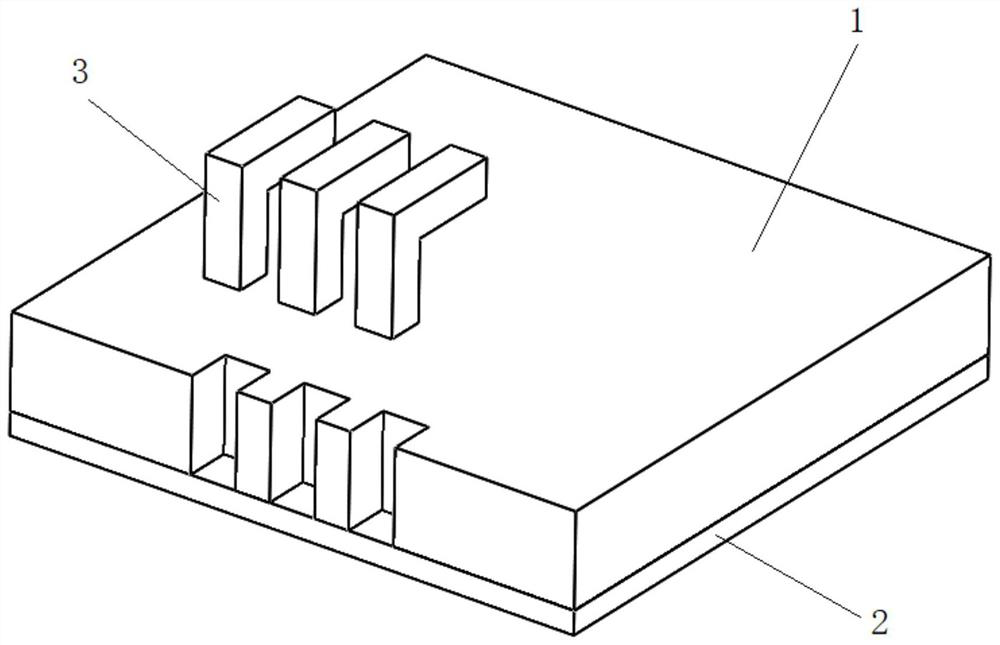

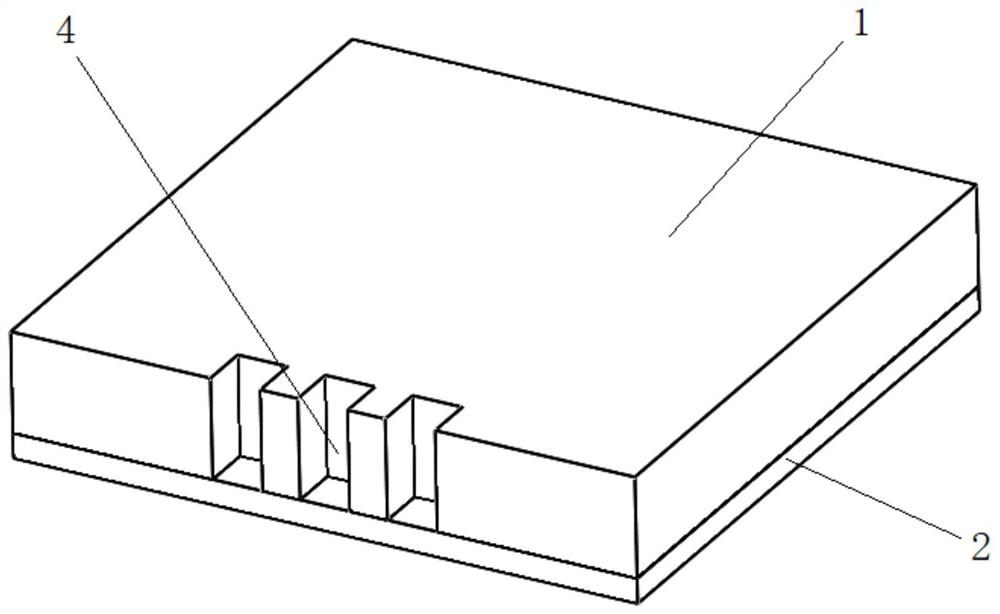

[0037] see Figure 1 to Figure 5 , a ceramic capacitive pressure sensor according to a preferred embodiment of the present invention, comprising a thick ceramic substrate (1), a thin ceramic substrate (2),

[0038] The thick ceramic substrate (1) and the thin ceramic substrate (2) are bonded and fixed through a glass paste bonding layer (5), and a plurality of grooves (4) are opened on the side edge of the thick ceramic substrate (1) , there are 3 grooves (4), each of which is filled with an L-shaped conductive sheet (3), between the conductive sheet (3) and the groove (4) Through the conductive connection of silver glue, there is also a pad (6) on the top groove of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com