Automatic assembling and machining production line for steering wheel assembly

A steering wheel and production line technology, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of low efficiency of manual assembly of steering wheels, achieve the effects of shortening oiling time, speeding up assembly efficiency, and solving low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

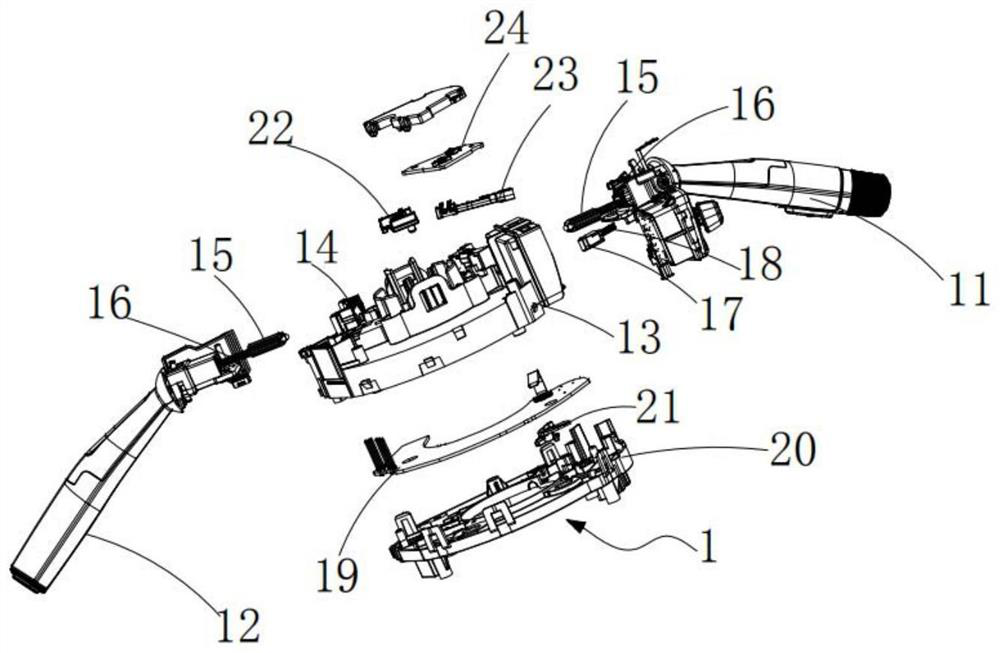

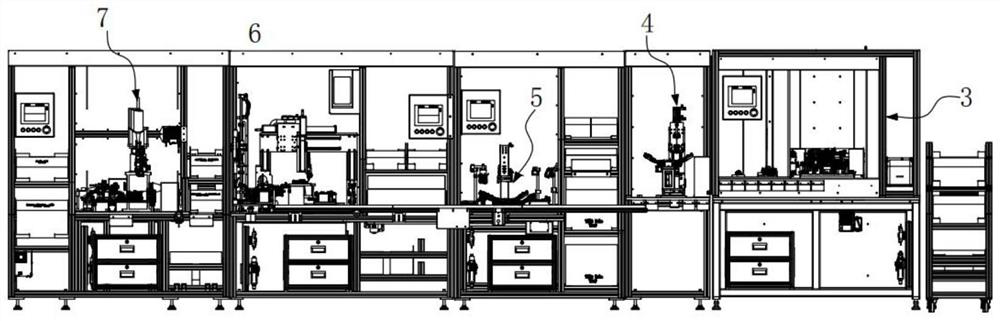

[0102] Such as Figure 1 to Figure 17As shown, an automatic assembly and processing production line for a steering wheel body assembly is used for assembling a steering wheel body assembly 1. The steering wheel body assembly 1 consists of a left handle assembly 11, a right handle assembly 12, a base 13, and a stop shifter. 14. Piston a15, spring a16, piston b17, spring b18, PCB main board 19, bracket cover 20, pawl 21, rotating carrier 22, contact module 23 and handle PCB board 24 are assembled to form the steering wheel The automatic assembly and processing production line of body assembly 1 includes in sequence according to the assembly sequence:

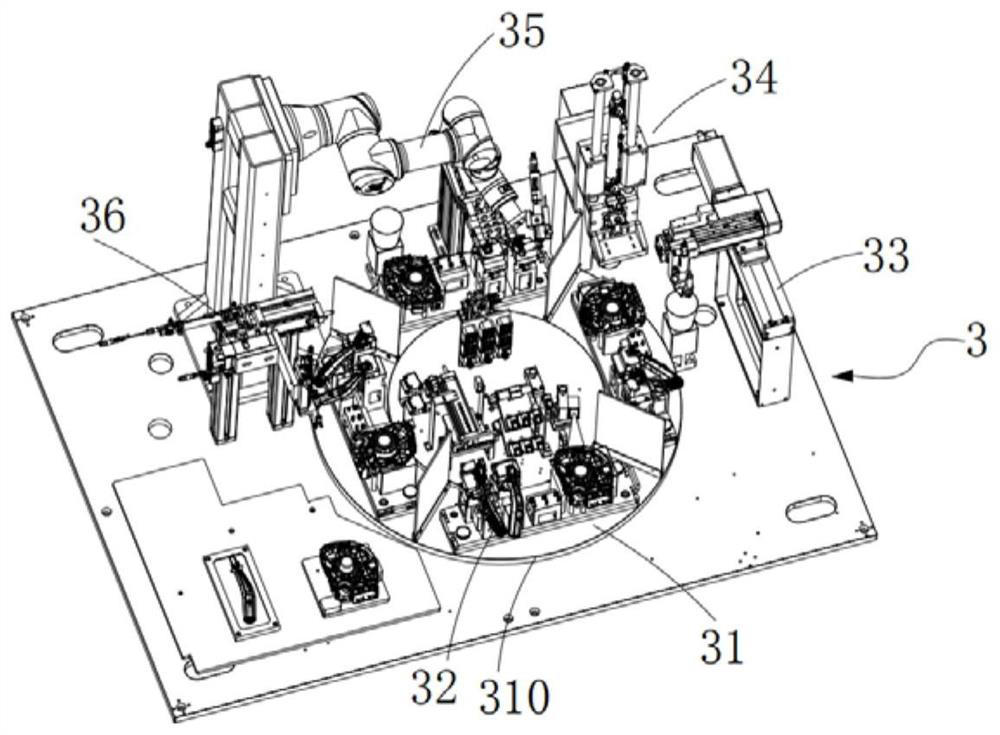

[0103] Turntable pre-assembly mechanism 3, said turntable pre-assembly mechanism 3 includes a turntable assembly 31, a loading assembly 32, a first oiling assembly 33, a press-fit assembly 34, a second oiling assembly 35, a pre-installation assembly 36 and an unlocking assembly 37 , a number of said loading assemblies 32 are equi...

Embodiment approach

[0108] As a preferred embodiment, the loading assembly 32 includes:

[0109] a bottom plate 321, the bottom plate 321 is arranged horizontally;

[0110] a base positioning unit 322, the base positioning unit 322 is arranged on the bottom plate 321, and it is used to carry the horizontally placed base 13;

[0111] The left handle positioning unit 323, the left handle positioning unit 323 is arranged on the bottom plate 321, which is used to carry the vertically arranged left handle assembly 11, and the left handle assembly 11 is equipped with the piston a15 The left handle notch 111 is located at the top setting;

[0112] The right handle positioning unit 324, the right handle positioning unit 324 is arranged on the bottom plate 321, which is used to carry the vertically arranged right handle assembly 12, and the right handle assembly 12 is equipped with the piston a15 The right handle notch 121 is located at the top setting; and

[0113] Material carrier 325, said material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com