Ship manufacturing and machining system

A processing system and ship technology, applied in the direction of manufacturing tools, metal processing equipment, grinding workpiece supports, etc., can solve problems such as being unsuitable for rust removal, and achieve the effects of high rust removal work efficiency, convenient operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

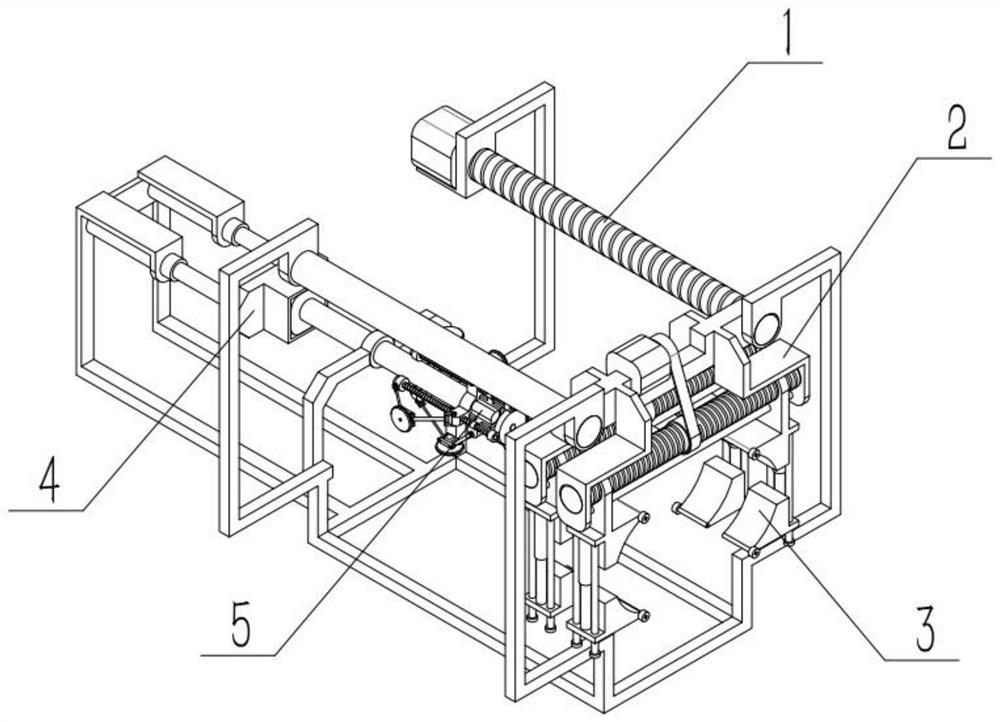

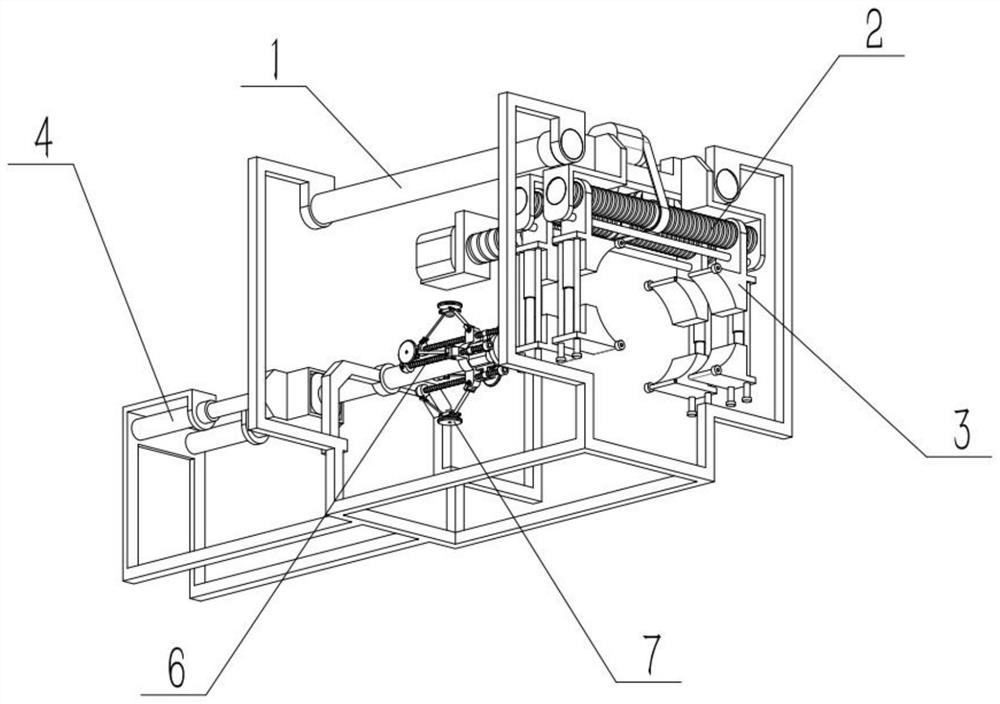

[0033] Such as Figure 1-11 As shown, a ship manufacturing and processing system includes a frame mechanism 1, a power mechanism 2, a clamping mechanism 3, a pushing mechanism 4, a transmission mechanism 5, a connecting rod mechanism 6 and a derusting mechanism 7, and the power mechanism 2 is connected to the frame At the right end of the mechanism 1, there are four clamping mechanisms 3, the left and right ends of the front and rear ends of the power mechanism 2 are respectively connected with a clamping mechanism 3, the pushing mechanism 4 is connected to the left end of the frame mechanism 1, and the transmission mechanism 5 is connected to the pushing mechanism 4 At the right end, four link mechanisms 6 are provided, and the four link mechanisms 6 are evenly arranged on the transmission mechanism 5 in the circumferential direction, and each link mechanism 6 is connected with a derusting mechanism 7 .

specific Embodiment approach 2

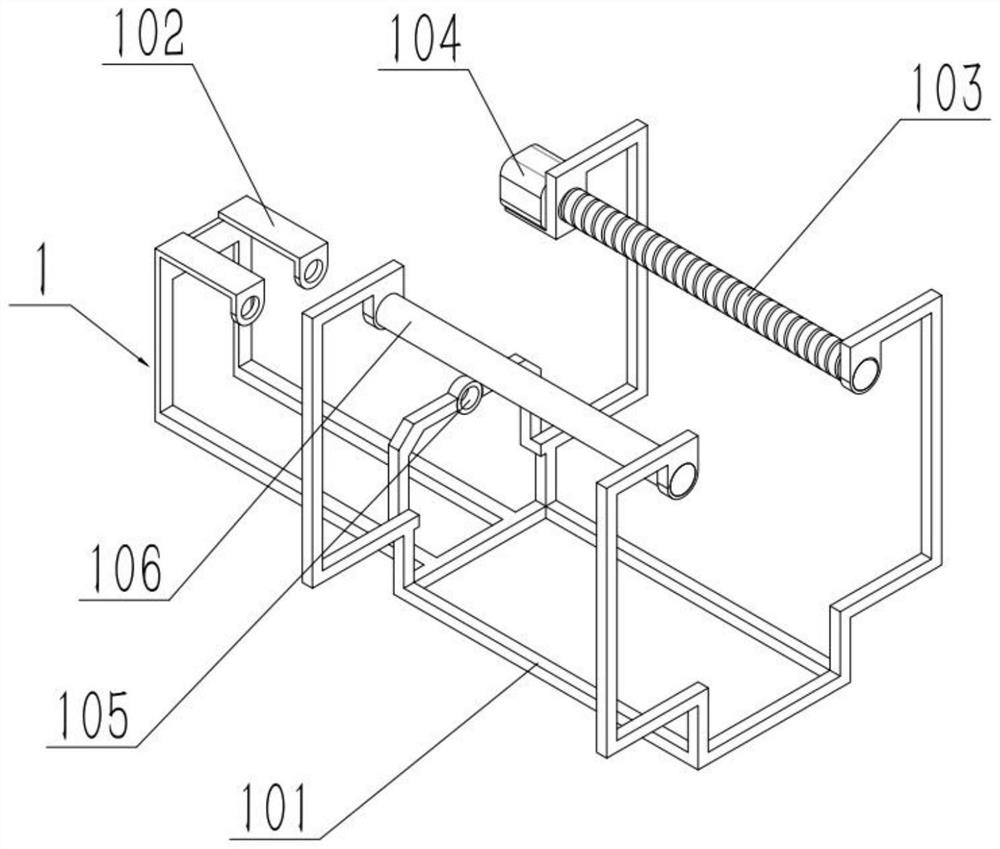

[0035] Such as Figure 1-11As shown, a ship manufacturing and processing system, the frame mechanism 1 includes a frame 101, a boss 102, a first screw 103, a first motor 104, a ring 105 and a slide bar 106, and two bosses 102 are provided, The two bosses 102 are fixed respectively at the front and rear ends of the left end of the frame 101, the first lead screw 103 is rotatably connected to the upper end of the right end of the frame 101, and the output shaft of the first motor 104 is fixedly connected with the first lead screw 103 through a coupling. , the first motor 104 is affixed to the right end of the frame 101 , the ring 105 is affixed to the middle of the frame 101 , and the slide bar 106 is affixed to the upper end of the rear end of the frame 101 . The structure is simple and reasonable for easy storage. When in use, driving the first motor 104 can drive the first lead screw 103 to rotate to provide power for subsequent rust removal. The inside of the ring 105 is pol...

specific Embodiment approach 3

[0037] Such as Figure 1-11 As shown, a ship manufacturing and processing system, the power mechanism 2 includes a power frame 201, a round hole 202, a second motor 203, a second screw 204, a first sprocket 205, a transmission chain 206, a long rod 207, a second Two sprocket wheels 208 and rod 209, the front and rear sides of power frame 201 front and rear upper ends are respectively provided with a round hole 202, and the left and right ends of power frame 201 lower ends rotate respectively and connect a second leading screw 204, each second leading screw 204 A first sprocket 205 is affixed to the middle of each, the output shaft of the second motor 203 is affixed to the rod 209 through a coupling, the second sprocket 208 is affixed to the rod 209, and the second sprocket 208 is connected to the two second sprockets. A sprocket 205 is connected through a transmission chain 206. The front and rear ends of the lower end of the power frame 201 are respectively fixed with a long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com