Laser derusting method and laser derusting device

A laser rust removal and laser technology, which is applied in laser welding equipment, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of long process time, low rust removal efficiency, and low efficiency, and achieve the effect of precise rust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

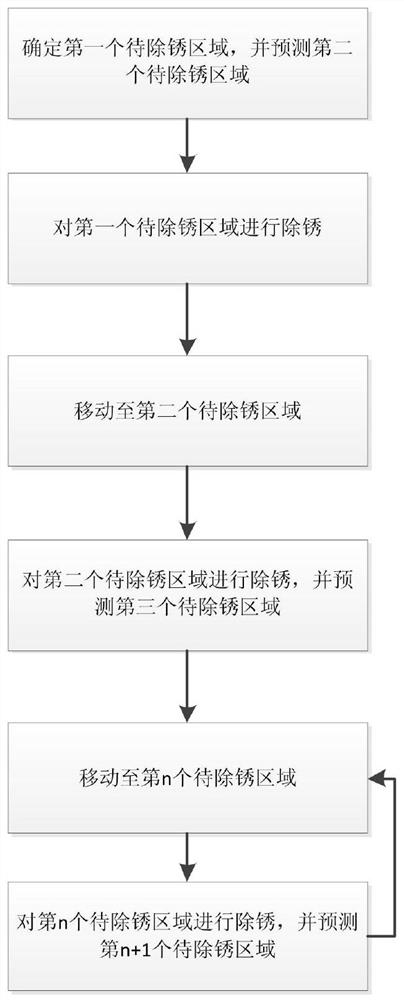

[0081] A laser rust removal method, comprising the following steps:

[0082] The first step is to determine the first area to be derusted by visual laser, and predict the second area to be derusted;

[0083] The second step is to correspond the rust removal laser to the first area to be removed, and perform the rust removal operation on the first area to be removed by the rust removal laser;

[0084] Step 3: According to the predicted position of the second rust-removing area, make the second rust-removing area correspond to the visual laser and rust-removing laser, perform rust removal operation on the second rust-removing area, and predict the first rust removal area. Three areas to be derusted;

[0085] Step 4: According to the predicted position of the nth rust-removing area, make the nth rust-removing area correspond to the visual laser and the rust-removing laser, perform the rust-removing operation on the nth rust-removing area, and predict the nth rust-removing area. ...

Embodiment 2

[0091] This embodiment is a specific optimization of the first embodiment.

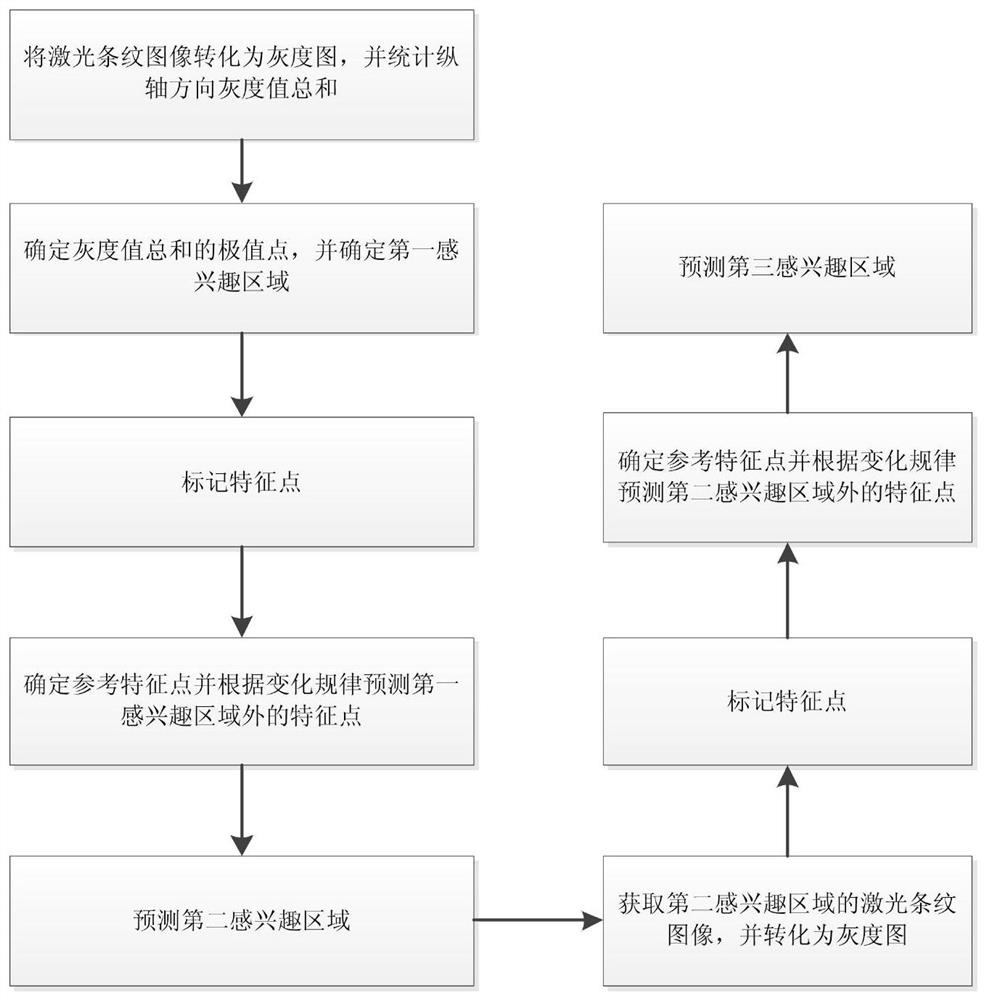

[0092] The method of the first step includes the following steps:

[0093] A1. Project the laser stripe onto the surface to be derusted, convert the laser stripe image within the visual range into a grayscale image, and count the sum of the grayscale values along the longitudinal axis of the laser stripe image;

[0094] A2. Determine the extreme point of the sum of gray values, and obtain the abscissa and ordinate of the laser fringe image at the corresponding position, and use the abscissa and ordinate as the center point to determine the first region of interest [region of interest, ROI], and set the first region of interest as the first region to be derusted;

[0095] A3. Mark multiple feature points in the first region of interest. The marking method is as follows: the gray value of the feature points is greater than the background threshold; the rusted points are generally diffused, that is, t...

Embodiment 3

[0114] This embodiment refines the rust removal method for the rust removal laser in the third step.

[0115] In conventional laser rust removal, long-term high-intensity irradiation may cause energy waste or damage to the substrate. The rust-removing method of the rust-removing laser in the present embodiment includes:

[0116] B1. Establish a one-dimensional linear heat conduction-energy conservation equation: where T is the temperature, j is the thermal conductivity, ρ is the material density, c is the material heat capacity, and Q is the external heat source of the laser;

[0117] B2. Establish a laser rust removal equation:

[0118] Wherein, h is the thickness of the rust layer, s is the rust removal time, A is the reflection coefficient of the steel to be removed to the laser, I 0 is the energy density of the laser, β is the absorption coefficient of the laser energy by the steel to be derusted, θ(h, s) is the initial temperature change value, and τ is the laser pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com