Fully automatic multi-angle pot surface grinding device

A multi-angle, fully automatic technology, applied in the direction of used abrasive processing devices, abrasives, abrasive jet machine tools, etc., can solve the problems of complex structure, affecting the grinding effect, affecting the efficiency of pot body grinding, etc., so as to achieve less grinding process , high grinding precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the present invention is further described:

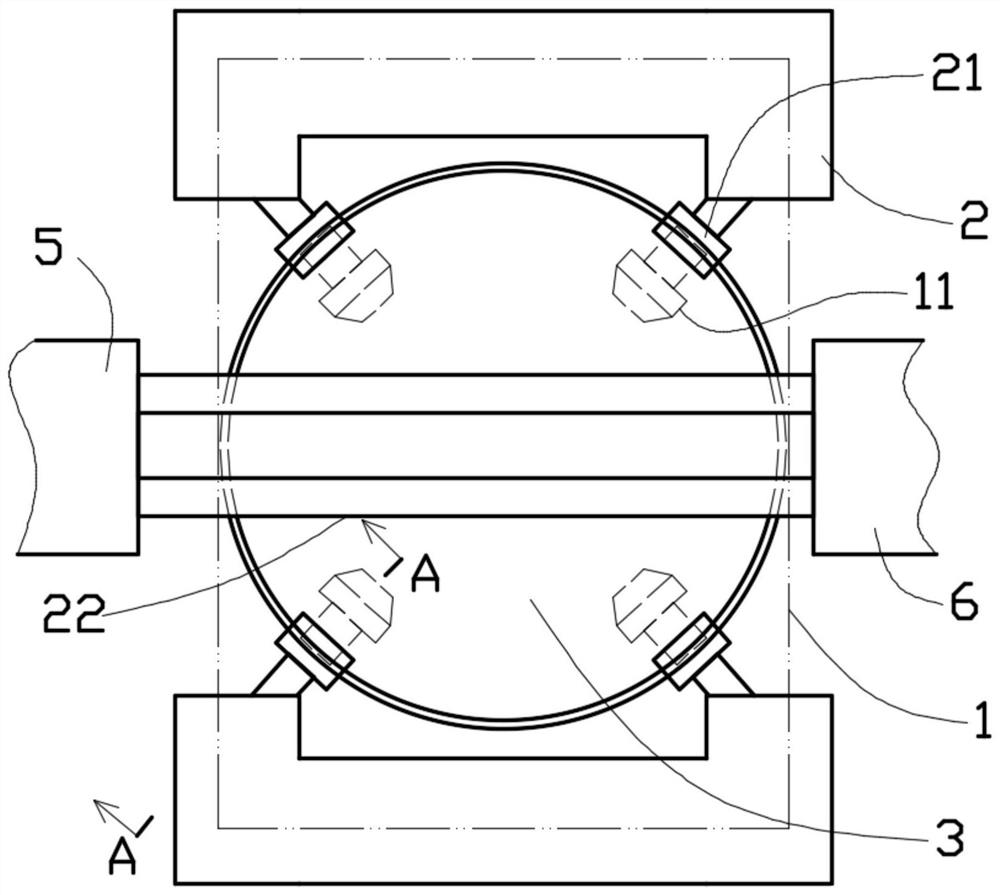

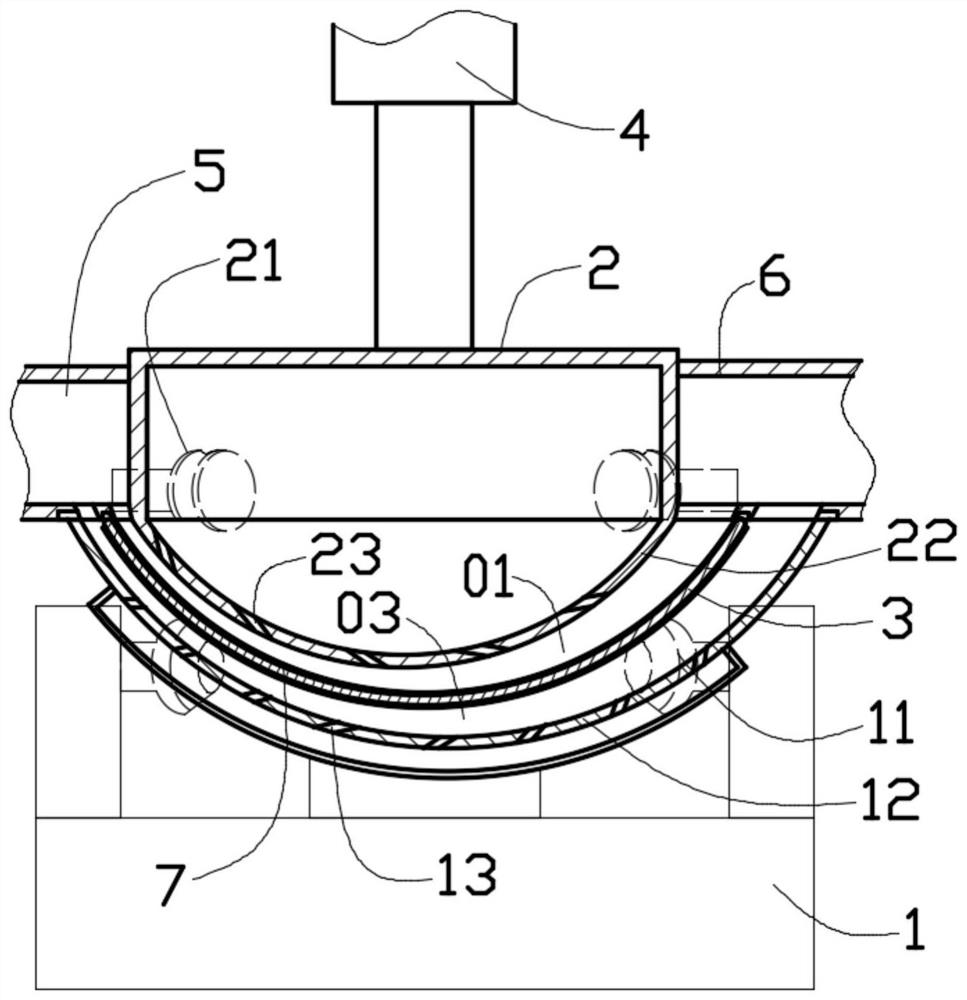

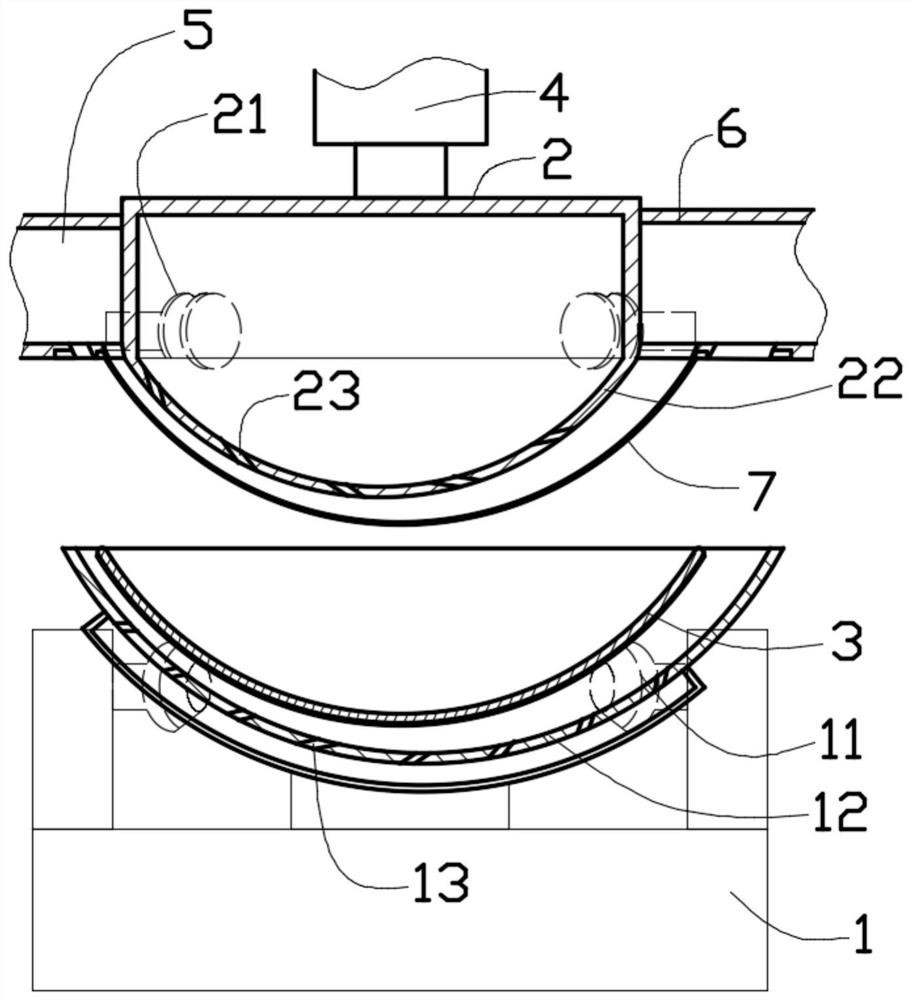

[0018] Such as Figure 1 to Figure 4 In the embodiment of the present invention, the fully automatic multi-angle pot surface grinding device includes a base 1 and a press table 2, and the base 1 is equipped with two sets of axially horizontal rotating wheels 11 at the front and rear, and the number of the rotating wheels 11 in the two groups is There are more than three, which are synchronously connected with the transmission module, that is, the rotation of the rotating wheel 11 can be controlled by the transmission structure. The pot body 3 to be processed is placed on the rotating wheel 11. The pot body 3 is a spherical pot bottom. Shape, the bottom spherical surface of the pot body 3 is close to the truncated cone-shaped side of the rotating wheel 11, the annular cone surface of the rotating wheel 11 matches the spherical size of the pot body 3, and the truncated cone-shaped side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com