A four-sided moulded, damage-resistant lumber feed wheel

A technology of four-sided planing and feeding wheel, which is applied in the direction of the workpiece feeding device, can solve the problems of large wood damage, damage, and large groove depth, etc., and achieve the effect of reducing production costs and reducing the probability of scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

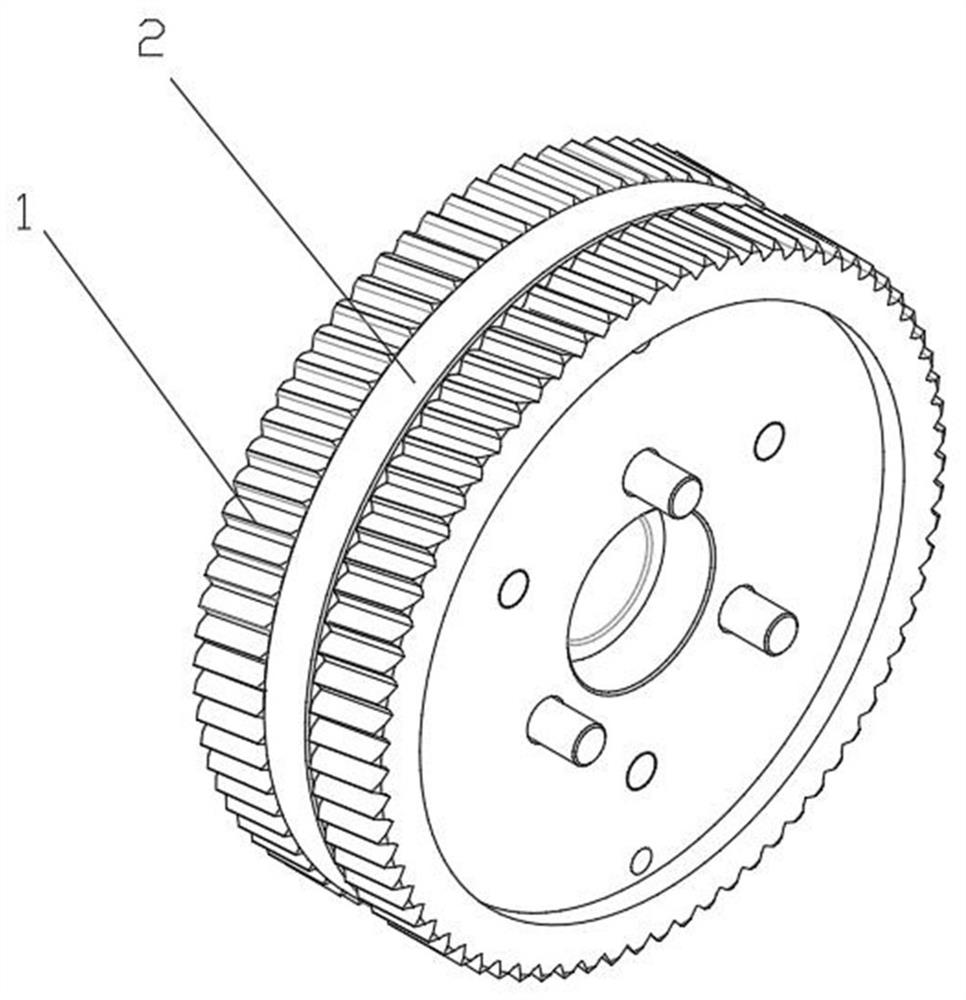

[0021] Such as figure 1 As shown, a four-sided planer anti-damage wood feed wheel includes two feed rollers 1 and a movable smooth roller 2, one of the two feed rollers 1 is provided with a protruding shaft 4, and the other feed roller 1 is sleeved On the protruding shaft 4, the outer diameter of the protruding shaft 4 is the same as the inner diameter of the other feed roller 1, and a bearing 9 is also sleeved on the protruding shaft 4, and the bearing 9 is located between the two feed rollers 1, and the active light The roller 2 is sleeved on the outer ring of the bearing 9. Wherein the outer diameter of the movable smooth roll 2 is smaller than the outer diameter of the feed roll 1, and the difference between the outer diameter of the movable smooth roll 2 and the outer diameter of the feed roll 1 is 2 mm. Gear teeth are arranged on the tread of the feed roller 1 to increase the gripping force of the feed roller to wood.

[0022] Such as figure 2 As shown, a shaft shoul...

Embodiment 2

[0028] Embodiment two, different from embodiment one is:

[0029] Such as image 3 and Figure 4 As shown, the feed wheel is not driven by a drive shaft, but is driven by a roulette, and the roulette and the feed wheel are connected by three screws, and the two feed rollers 1 are provided with holes for passing through the screws to connect with the roulette . Because there is no drive shaft to directly drive, no keyway is provided on the protruding shaft 4 , and the diameter of the hollow part on the protruding shaft 4 is the same as the inner diameter of another feeding roller 1 . The outer diameter of the protruding shaft 4 is the same as the inner diameter of the annular protrusion 5 on the other feed roller 1, that is, the end face of the protruding shaft 4 abuts against the other feeding roller 1, and the annular protrusion 5 is sleeved on the protruding shaft 4, At this time, the annular protrusion 5 plays two roles of positioning the two feeding rollers 1 and limiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com