Laser ranging dynamic detection belt deviation system

A technology of dynamic detection and laser ranging, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low degree of automation, prone to false alarms, low production efficiency, etc., and achieve high degree of automation, strong real-time performance, The effect of simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

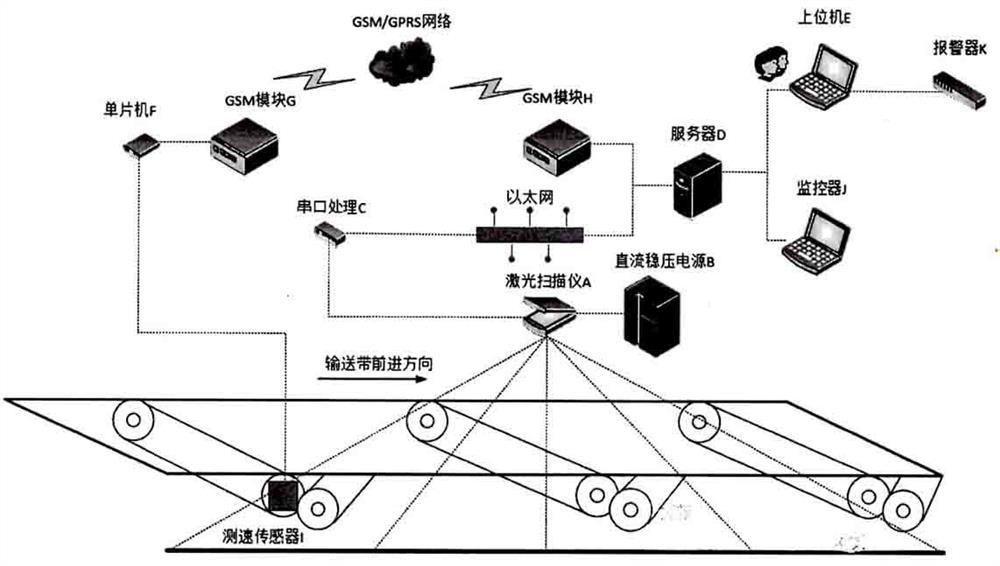

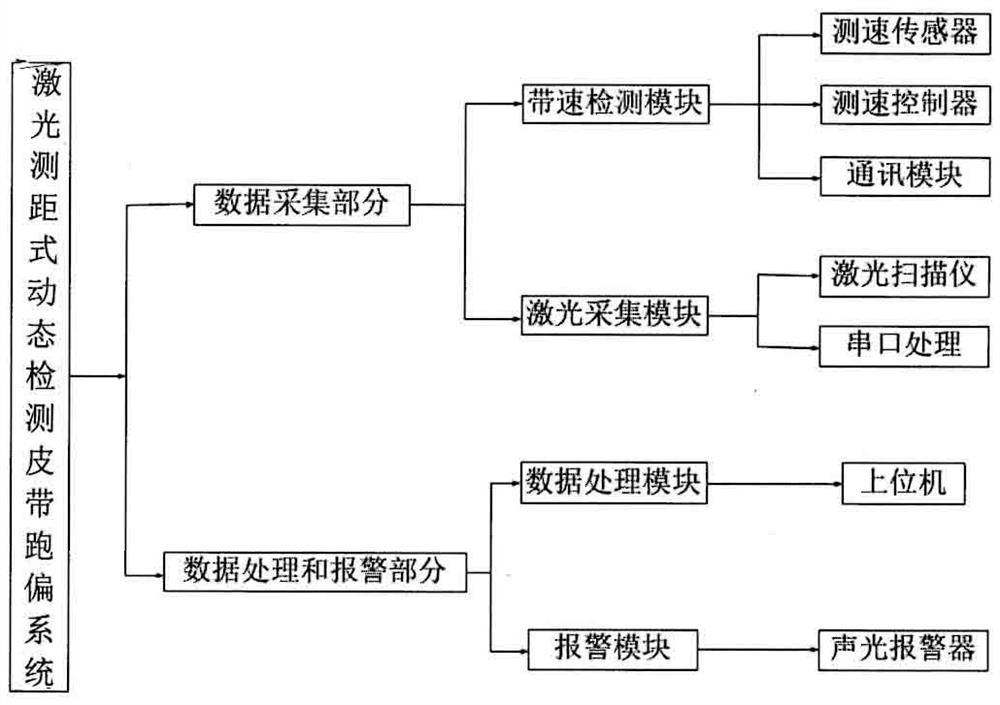

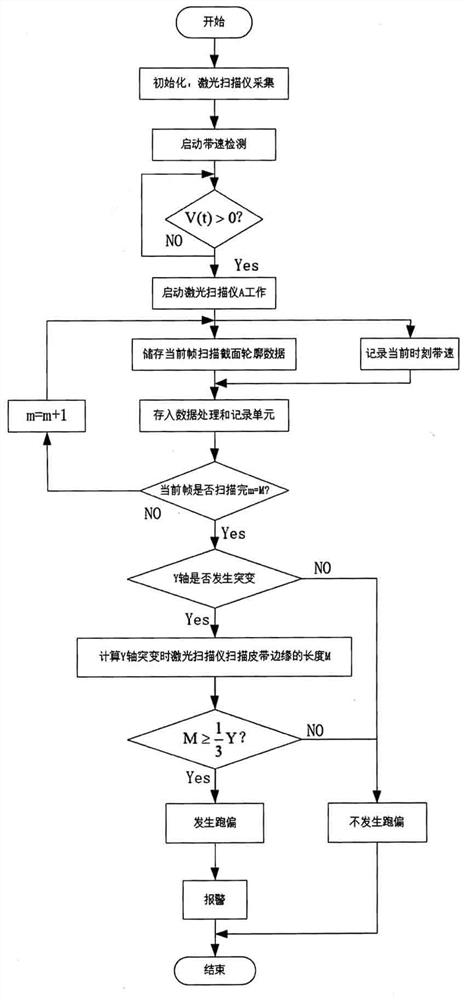

[0036] A laser ranging type dynamic detection belt deviation system, including a belt conveyor 1, a laser scanner A, a serial port processor C, a speed sensor I, a single-chip computer F, and a host computer H; the laser scanner A is fixedly installed on the conveyor belt The side of the edge, the installation distance meets the error range of the belt deviation, and the scanning surface of the laser scanning distance measuring device is perpendicular to the horizontal plane and the ground of the belt; the laser scanning data is sent to the Ethernet by the serial port processor C for remote transmission; the speed sensor I is fixed on the central axis of the uplink roller of the belt conveyor, and rotates coaxially with the roller; the belt speed data is collected by the single-chip microcomputer F and transmitted to the remote host computer through the GSM / GPRS module; the host computer E is based on the measurement data of the detection system, real-time Calculate and realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com