A method for belt deviation alarm emergency stop with belt edge detection

An edge detection and belt technology, used in conveyor objects, conveyor control devices, transportation and packaging, etc., can solve problems such as poor stability, conveyor belt deviation, conveyor belt misreporting and correction, and achieve low cost and real-time performance. Strong, strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

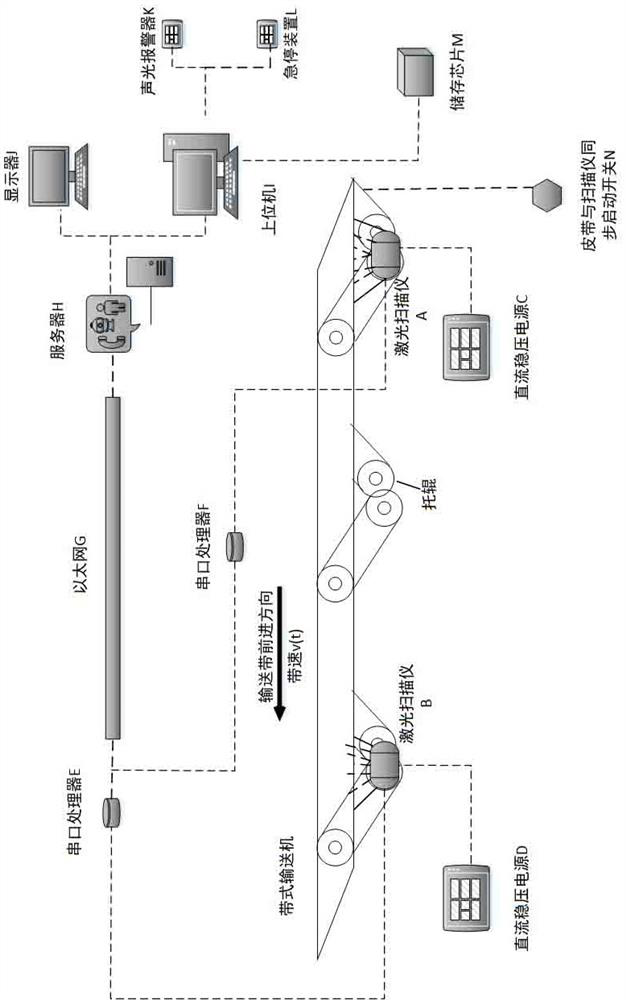

[0042] Take single roller or trough belt conveyor as an example, such as figure 1 shown. Among them are belt conveyors (trough or straight, including basic configurations such as driving motors and rollers), laser scanner A, laser scanner B, DC regulated power supply C, DC regulated power supply D, serial port processor E, serial port processor F, Ethernet G, server H, host computer I, display screen J, sound and light alarm K, emergency stop device L, storage chip M, belt and scanner synchronous start switch N. Laser scanner A and laser scanner B are respectively located on the belt bracket next to the lower and upper rollers of the conveyor belt, and in the same plane as the conveyor belt, so that the laser scanner is perpendicular to the edge section of the belt to scan the sector area, and the scanning distance should be ensured The range should be greater than the belt thickness to obtain the lateral distance of the belt edge from the belt pulley edge support. Laser sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com