Application method of friction liner capable of detecting steel wire rope tension and alarming

A friction pad, wire rope technology, applied in tension measurement, measuring device, force/torque/work measuring instrument, etc., can solve the problems of reducing the service life of wire rope, broken wire and strand of wire rope, tilting of lifting container, etc., to reduce safety Accidents, tension balance, effects of improving management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

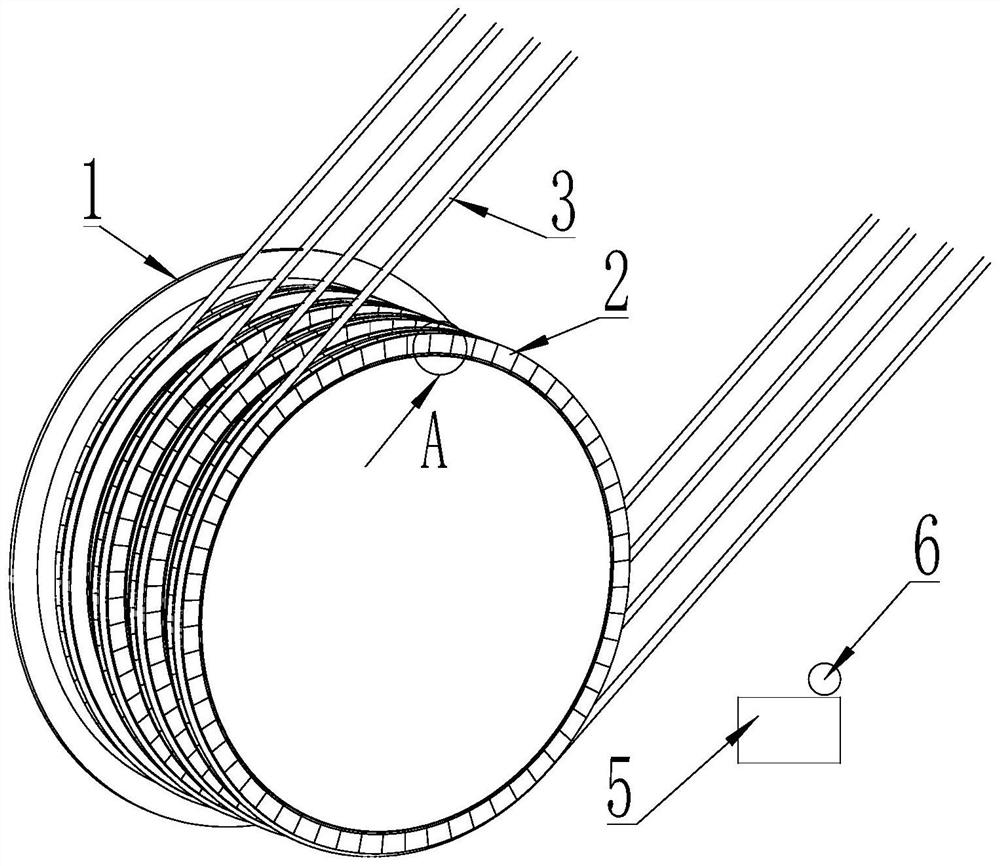

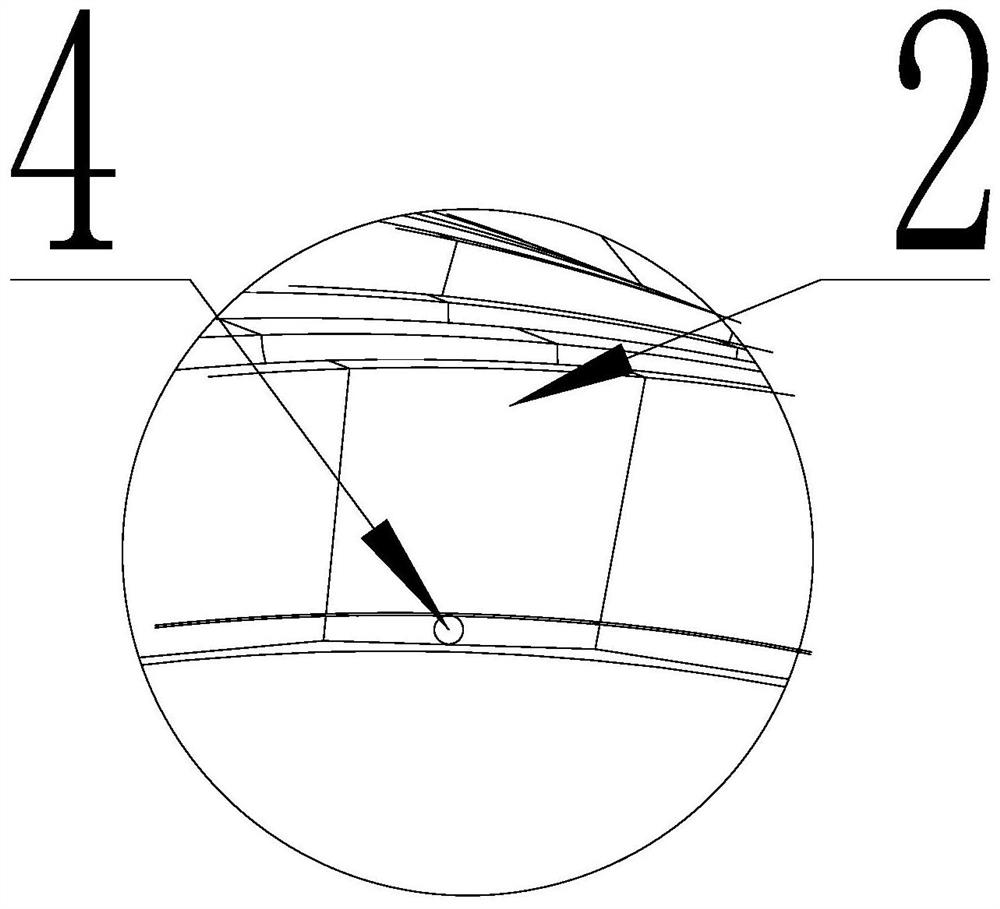

[0015] The friction lining 2 is evenly distributed on the horizontal axis of the drum 1, the steel wire rope 3 is wound and arranged in the groove of the friction lining 2, at least one sensor 4 is arranged on the lower surface of the friction lining 2, a controller 5 is arranged on one side of the drum 1, and the sensor Wire is set between 4 and controller 5, and alarm bell 6 is set on controller 5, and wire is set between controller 5 and alarm bell 6.

Embodiment 2

[0017] The sensor 4 is wirelessly connected to the controller 5 .

Embodiment 3

[0019] A method for using a friction liner capable of detecting steel wire rope tension and alarming according to claim 1, characterized in that: when the tension of the steel wire rope 3 on the drum 1 is unbalanced, the corresponding friction liner 2 on the drum 1 The sensor 4 sends a signal to the controller 5 through a wire. After the controller 5 receives the signal from the sensor 4, it starts the alarm bell 6 to give an alarm. At the same time, the display of the controller 5 displays the serial number corresponding to the sensor 4. The information adjusts the tension corresponding to the steel wire rope 3, so that the average tension of the steel wire rope 3 on the drum 1 is within the allowable range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com