Equivalent collision rigidity ejector for near-wall damage detection

A damage detection and catapult technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of large environmental impact, affecting the detection effect, and not being able to reflect structural damage well, and achieve accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

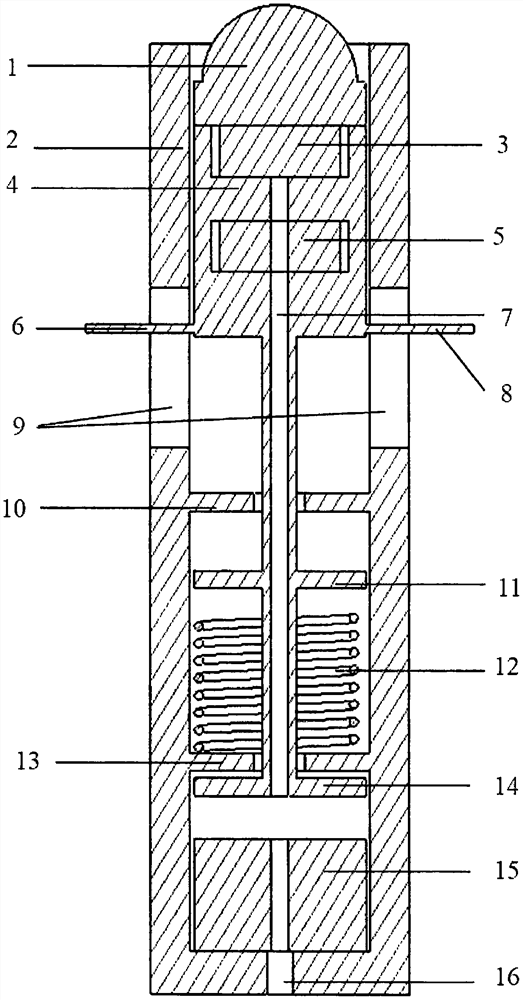

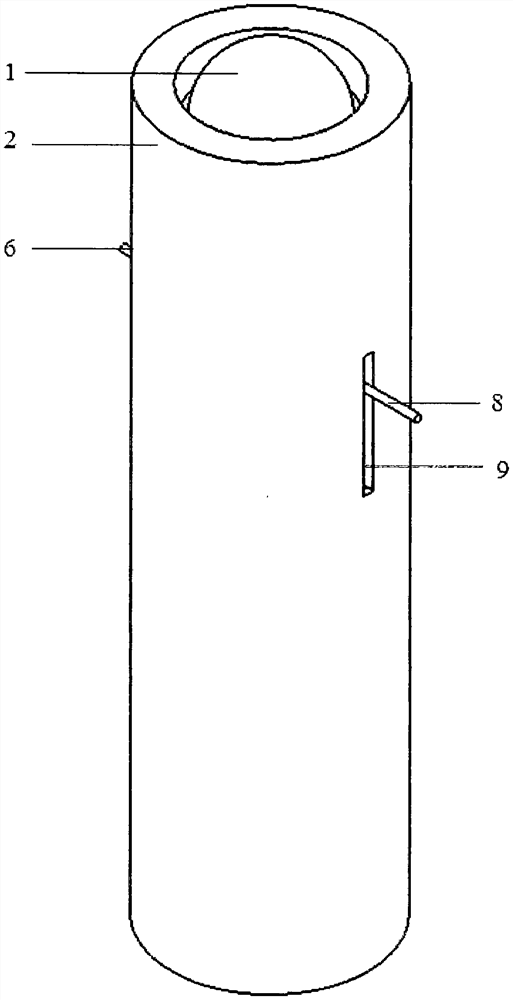

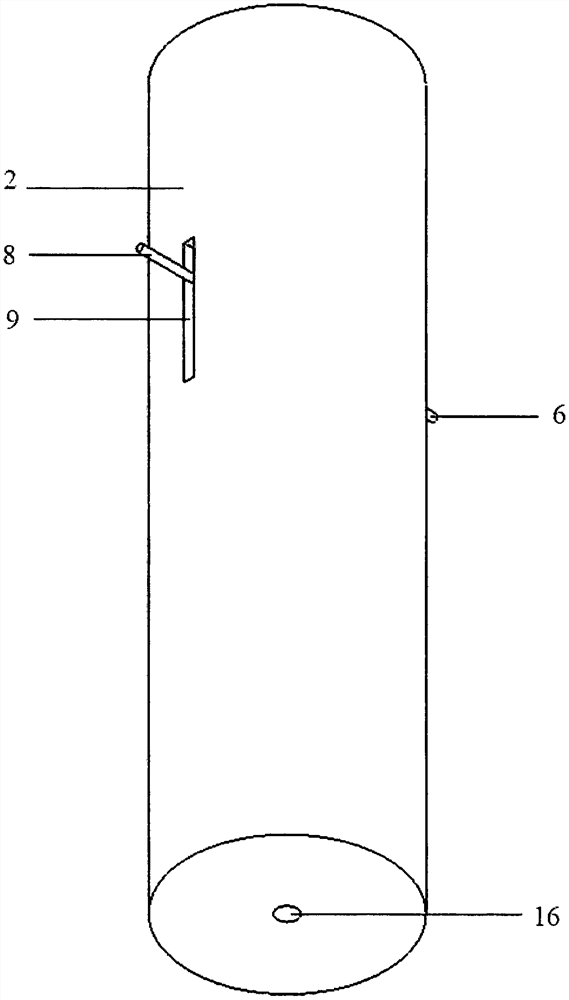

[0031] Such as Figure 1-Figure 5 Shown, the present invention proposes surface impact stiffness ejection measurement device, by hammer head (1), shell (2), force sensor (3), driving hammer seat (4), acceleration sensor (5), driving hammer seat left lever (6), the through hole (7) in the drive hammer seat, the right lever of the drive hammer seat (8), the slideway of the shell lever (9), the upper circular baffle at the center of the shell (10), the upper pressure plate of the drive hammer seat (11 ), spring (12), shell center bottom circular baffle plate (13), driving hammer seat bottom pressure plate (14), electric sucker (15), and the detailed structures such as shell bottom through hole (16). Wherein, the electric sucker (15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com