Method and system for detecting contactor adhesion

A contactor and heating contactor technology, applied in instruments, measuring devices, measuring electrical variables, etc., can solve the problem that the main negative contactor and the pre-charged contactor cannot be determined to stick, and achieve the effect of efficient and convenient sticking fault troubleshooting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

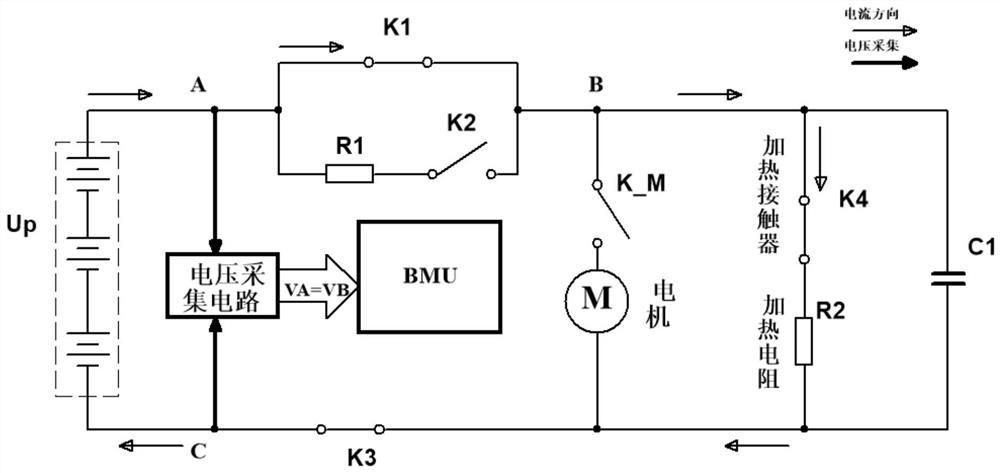

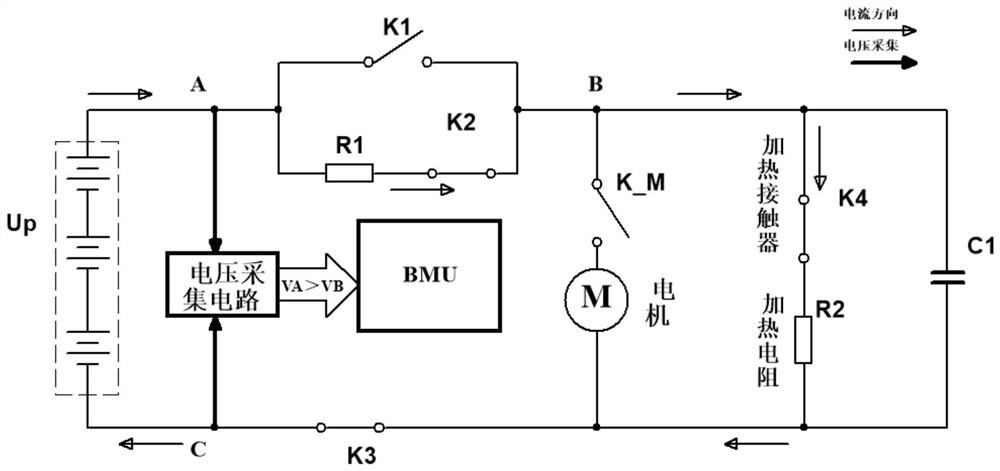

[0056] An embodiment of the present invention provides a method for detecting contactor adhesion, the method comprising:

[0057] It is determined that there is contactor adhesion in one of the first contactor branch and the second contactor branch, wherein the first contactor branch is connected in series with the power battery and the load branch in the working state to form a power supply circuit The second contactor branch of the power supply circuit is connected in parallel with the first contactor branch, and the resistance of the second contactor branch is different from the resistance of the first contactor branch;

[0058] Drive the load branch into a load working state, and then obtain the circuit parameter change of the first contactor branch or the second contactor branch, and determine the first contactor branch through the circuit parameter change there is contactor sticking or there is contactor sticking in said second contactor branch;

[0059] The first conta...

Embodiment 2

[0077] An embodiment of the present invention provides a system for detecting contactor adhesion, the system includes:

[0078] The battery management system is configured to determine that there is contactor adhesion in one of the first contactor branch and the second contactor branch, wherein the first contactor branch is connected to the power battery and the load in the working state The branches are connected in series to form a power supply circuit, and the second contactor branch is connected in parallel with the first contactor branch relative to the power supply circuit, and the resistance of the second contactor branch is the same as that of the first contactor branch The resistance of the circuit is different;

[0079]The battery management system is further configured to drive the load branch into a load working state, and then obtain the change of the circuit parameter of the first contactor branch or the second contactor branch, through the circuit The parameter...

Embodiment 1 and Embodiment 2

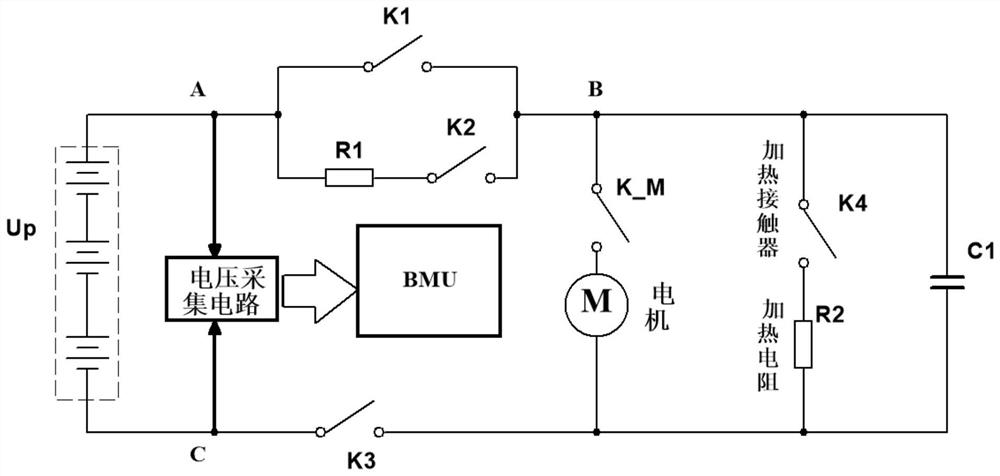

[0082] Based on Embodiment 1 and Embodiment 2, the embodiment of the present invention provides a circuit with a function of detecting contactor adhesion, the circuit includes:

[0083] Power battery and load branch;

[0084] The first contactor branch is used to form a power supply circuit in series with the power battery and the load branch in the working state;

[0085] a second contactor branch for parallel connection with the first contactor branch in the power supply circuit;

[0086] A battery management system, configured to detect circuit parameters of the first contactor branch or the second contactor branch, and to determine that one of the first contactor branch and the second contactor branch is in contact device adhesion, selectively driving the load branch to enter the load working state;

[0087] Wherein, the resistance of the second contactor branch is different from the resistance of the first contactor branch;

[0088] Such as figure 1 , the power batter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com