Centrifugal high-speed air compressor for fuel cell, and cooling structure of centrifugal high-speed air compressor

A fuel cell and cooling structure technology, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of poor rotor cooling effect, demagnetization of magnetic steel, disadvantage of protecting rotor, etc., so as to improve cooling effect and avoid magnetic steel. The effect of demagnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

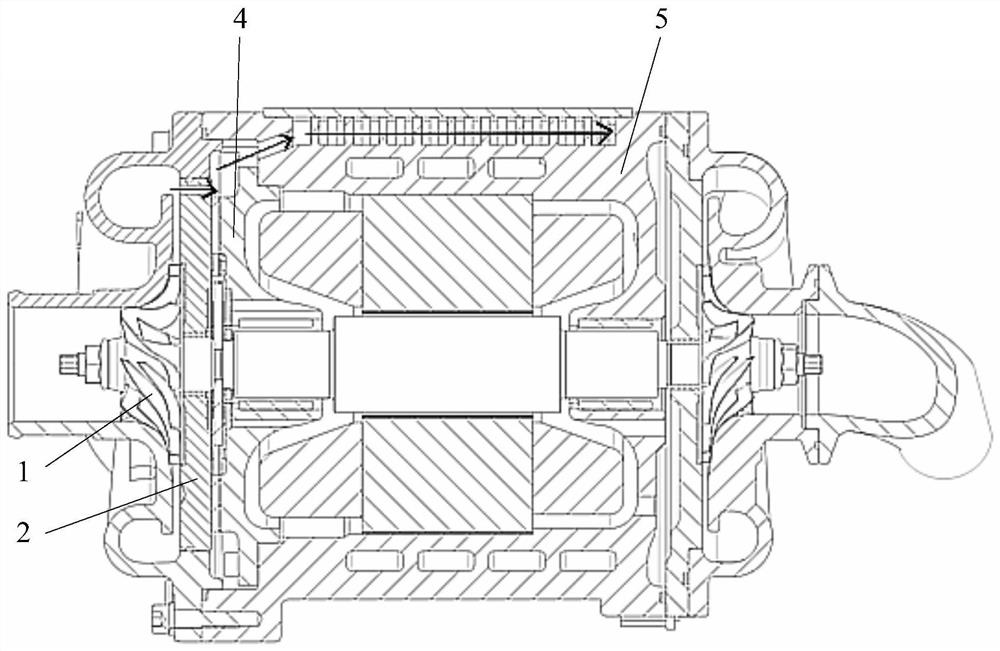

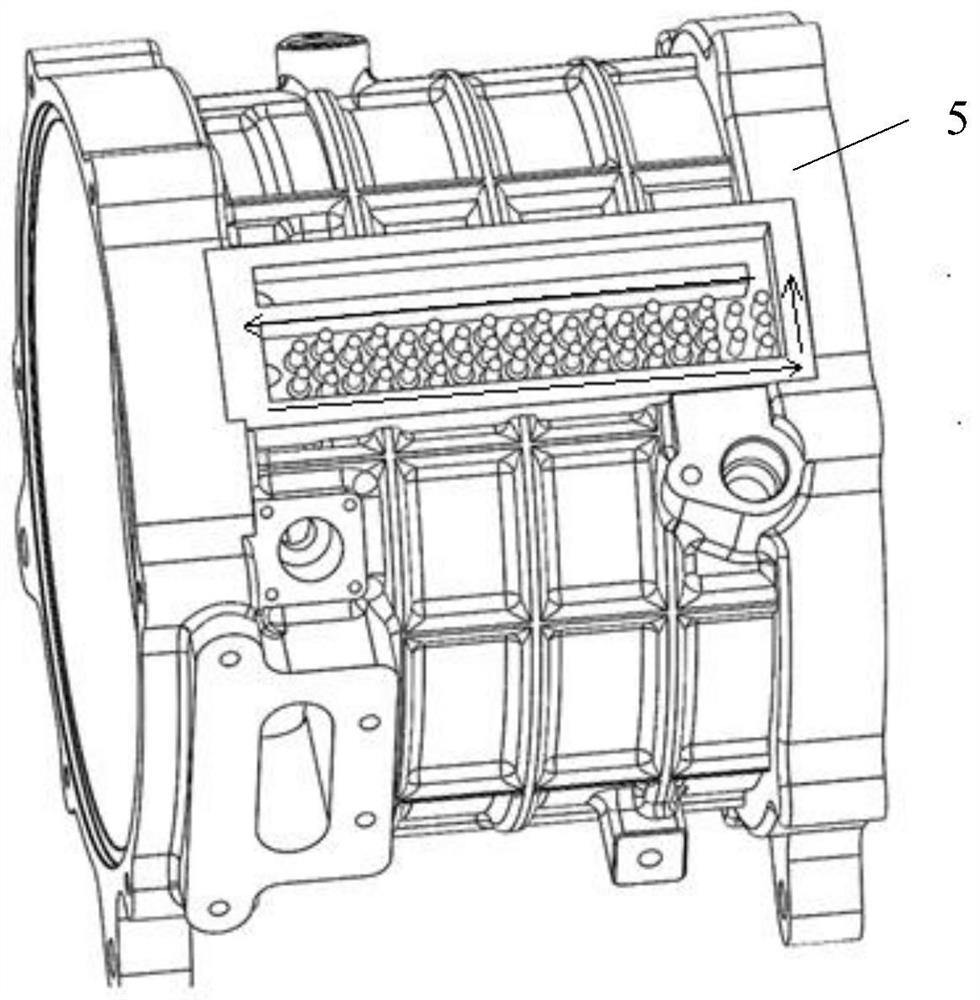

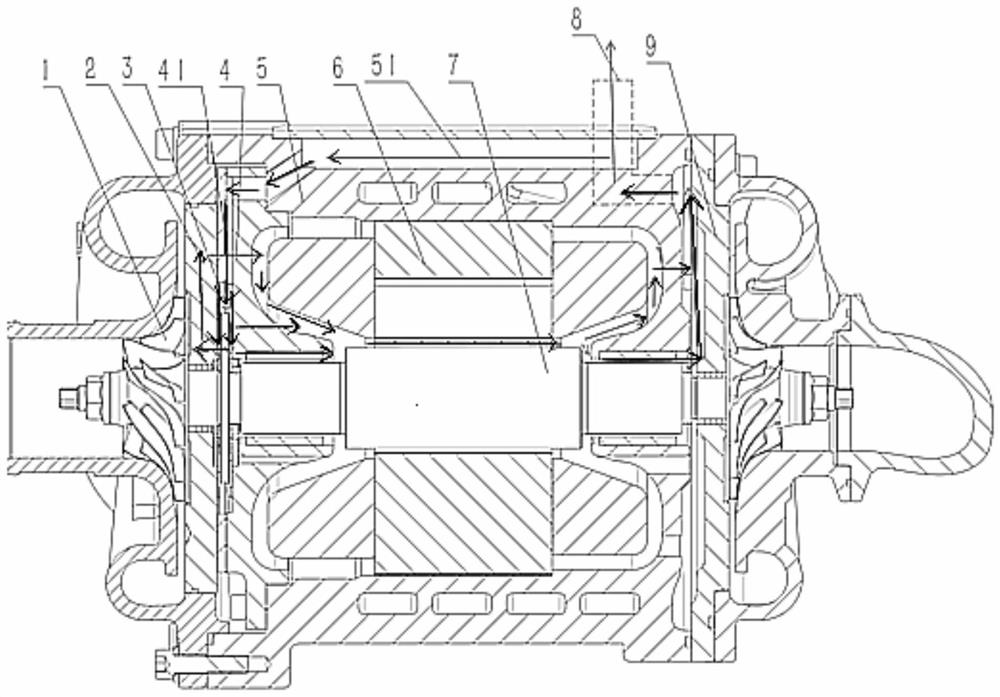

[0023] The embodiment of the present invention discloses a cooling structure of a centrifugal high-speed air compressor for fuel cells, which can draw gas from the volute and transport it to a heat exchanger for pre-cooling with cold water, and then transport the cooled gas to The rotor of the motor is cooled to improve the cooling effect of the cold air on the rotor and avoid demagnetization of the magnetic steel of the rotor. The embodiment of the present invention also discloses a centrifugal high-speed air compressor for a fuel cell, which can improve the reliability of the rotor by applying the cooling structure.

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap