Sand making machine

A sand making machine and shell technology, which is applied in mechanical equipment, vibration suppression adjustment, grain processing, etc., can solve the problems of incomplete crushing of crushed materials, difficulty in meeting established standards, and damage to components, so as to optimize the effect of impact crushing and prevent The effect of violent shaking and reducing the vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

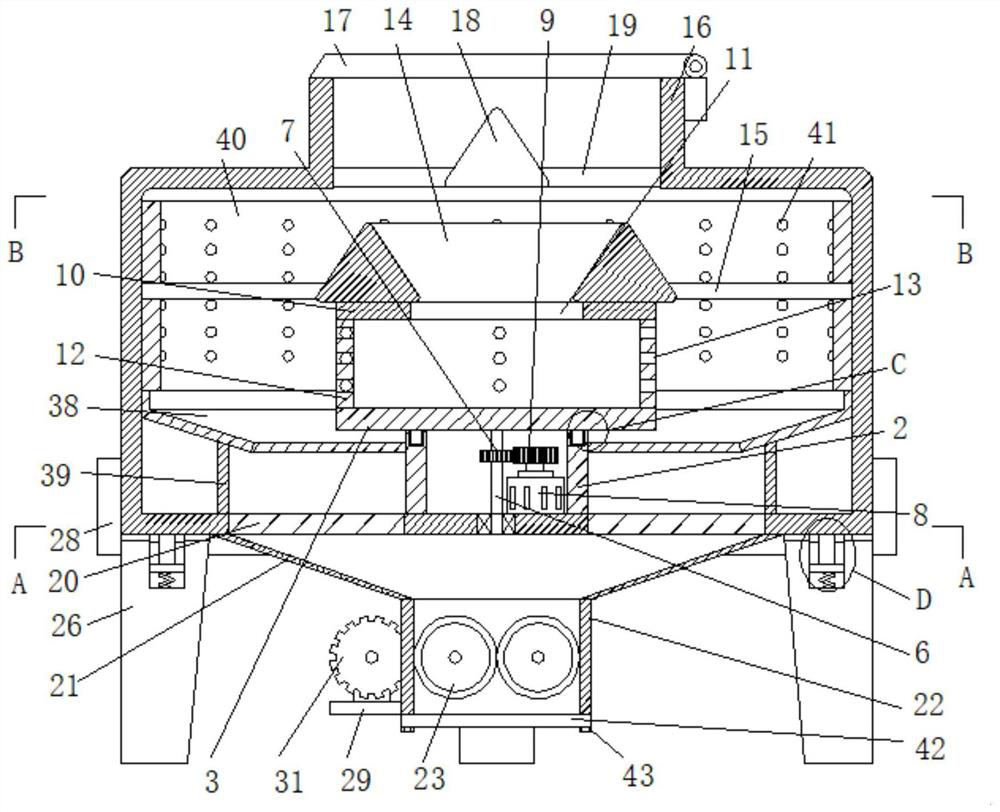

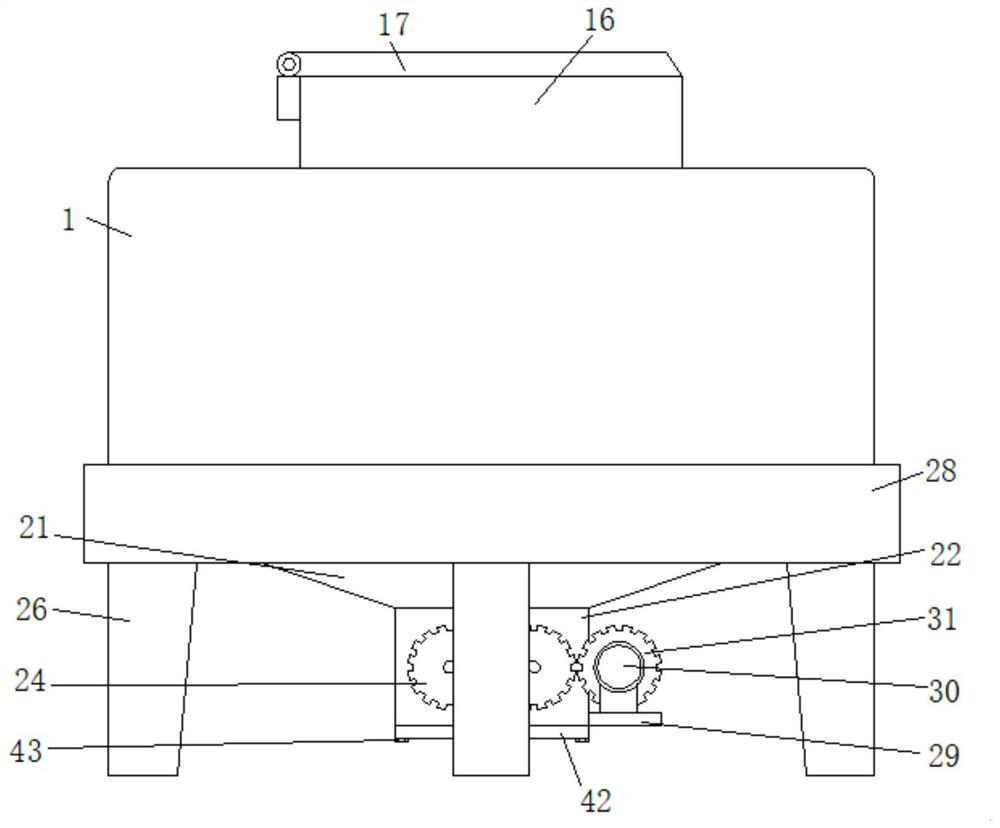

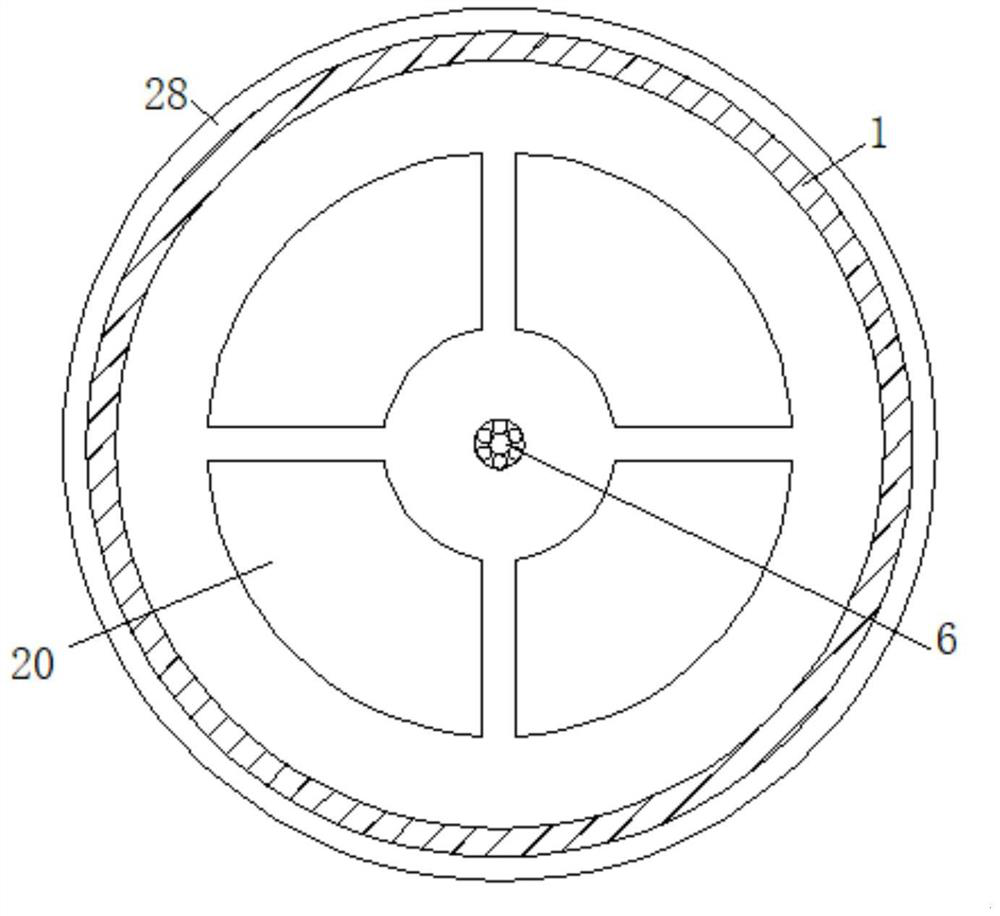

[0033] Embodiment one, such as Figure 1-8As shown, a sand making machine includes a horizontally arranged casing 1, the casing 1 is cylindrical, the inner bottom surface of the casing 1 is fixedly connected with a central cylinder 2, and a first rotating plate 3 is horizontally arranged above the central cylinder 2, The bottom surface of the first rotating plate 3 is fixedly connected with a fixed ring 4, and the upper surface of the central cylinder 2 is provided with a fixed groove 5 that matches the fixed ring 4. The fixed groove 5 is annular, and the fixed ring 4 is rotationally connected with the fixed groove 5. The first The bottom surface of the rotating plate 3 is fixedly connected with a main shaft 6, and the main shaft 6 is vertically arranged. The shaft of the motor 8 is fixedly connected to the second gear 9, and the second gear 9 is meshed with the first gear 7. A second rotating plate 10 is horizontally arranged above the first rotating plate 3, and a circular o...

Embodiment 2

[0034] Embodiment two, such as figure 1 , 2 , 5, the driving mechanism 25 includes a base plate 29 fixedly connected with the tank body 22, the base plate 29 is horizontally arranged, the upper surface of the base plate 29 is fixedly connected with a second motor 30, and the shaft of the second motor 30 is fixedly connected with a driving gear 31. One of the driven gears 24 is meshed with the driving gear 31, and the second motor 30 is used to drive the crushing roller 23 to operate to perform secondary crushing on the crushed materials, so that the crushing effect of the crushed materials is better.

Embodiment 3

[0035] Embodiment three, such as figure 1 , 7 As shown, the shock absorbing mechanism 27 includes a plurality of shock absorbing columns 32 fixedly connected to the outer bottom surface of the casing 1. The plurality of shock absorbing columns 32 are all vertically arranged, and the upper surfaces of the plurality of supporting columns 26 are provided with grooves 33. The bottom end of the shock-absorbing column 32 is fixedly connected with a sliding plate 34, the sliding plate 34 is slidingly connected with the groove 33, the sliding plate 34 is fixedly connected with the inner wall of the groove 33 through a spring 35, and the inner port of the groove 33 is fixedly connected with a limiter 36, The shock-absorbing column 32 is slidingly connected with the stopper 36, the groove 33 is cylindrical, the sliding plate 34 is circular, the stopper 36 is ring-shaped, and the stopper 36 is sleeved on the shock-absorbing column 32 to support The upper surface of the column 26 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com